For £4,395 the Robot Bike Co (RBC) will build customers a bespoke frame with carbon fibre components and tubing bonded into the double lap joints of additive manufactured lugs made from powdered titanium.

Despite the price tag, RBC maintains that the R160 fulfils criteria missing in today's mountain bikes, with AM parts allowing for customisation in a market more used to moulding carbon fibre frames in three sizes. RBC founding partner Ed Haythornthwaite added that technology developments would eventually bring bespoke bikes to a wider market.

To order a frame, customers use RBC's website to input their height, inside leg measurements and arm span, from which the size of the frame is then calculated. A CAD model of the entire bike frame is quickly generated to ensure the optimum fit, with 11 titanium lugs built around the customers’ exact requirements.

Bath-based HiETA, a specialist AM development and project engineering company, introduced RBC to project partners Altair and Renishaw and also provided the frame's parametric CAD model. They say that 225,720 geometries are possible.

RBC said it has placed high-strength-to-weight ratio titanium in areas of maximum stress and connected them together with high-stiffness-to-weight carbon composite tubes.

"One of the key things is those double lap joints," said Haythornthwaite. "We've seen bonded frames in the past and where they fail. [By using AM] it not only reduces peel loads, but also the way we fill...the double lap joint with adhesive. When we push the joint in the tube it splurges out any excess, ensuring the [Henkel] adhesive is absolutely covered, [ensuring] the best possible joint.

"We couldn't produce that shape by any other sculpt, basically 1mm wall thickness, [and] a very fine gap going down 25mm.

The lugs – titanium grade Ti6AI4V - are batch processed by Renishaw with SLS (selective laser sintering) of Ti particles in the 10-45μm range prior to heat treatment and CNC machining for bearing, headset, and bottom bracket fit.

Double lap shear joints are used to avoid so-called out of plane loads and AM allows RBS to produce parts with higher aspect ratios, thinner walls and more control over wall thickness tapering compared to a cast or machined parts.

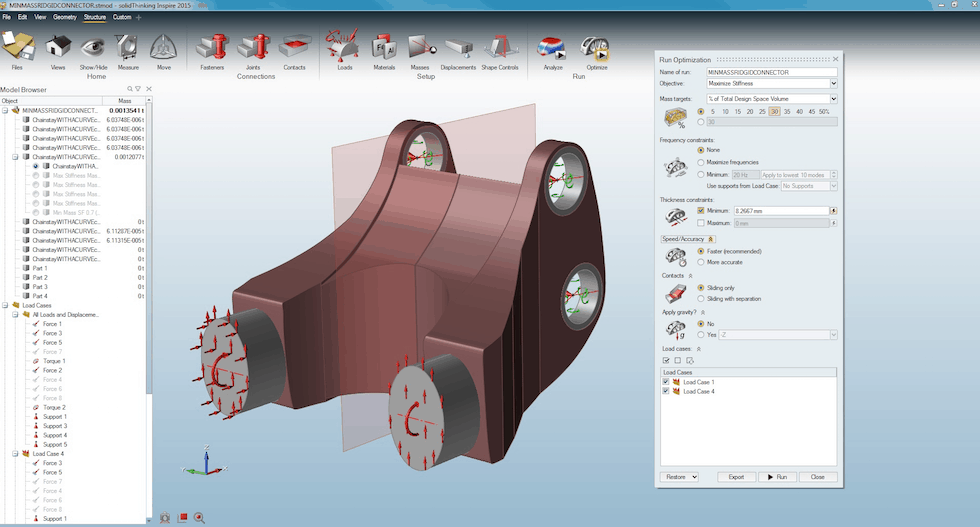

Altair were pivotal to AM part optimisation with solidThinking Inspire helping to identify where material in the connectors could be removed to save weight and reduce the number of parts used. The simulation experts took the original 3-piece chain-stay lug design to a single, hollow-walled component that is lighter, strong and requires minimal support structure during AM build.

According to Haythornthwaite, Altair's input into the R160 ensures there'll be no fatigue issues, adding that RBC would have struggled to get it to ascertain correct weight and strength ratios without Altair’s topology optimisation software.

RBC said it would take around four weeks to produce a frame with the finished bike fitted with a suspension system designed and developed by David Weagle.

Mike Adams, HiETA's CEO said AM parts will add value to products and that mass customisation is one of the AM industry's goals.

Echoing these sentiments, Haythornthwaite said: "We know the price of these parts is only going to go in one direction: they're going to get cheaper, so if we can make it a viable product now it will only become better in the future.

Swiss geoengineering start-up targets methane removal

Several rather dubious statistics in this report. IF methane had 120× the thermal effect of CO2 that would be TWO orders of magnitude. Two is not...