There have also been changes in technology: solidsand feature-based machining systems and tools such as verifiers and simulators have caught on with a vengeance. Generally, buying decisions are more clear-cut than in the CAD market and are not adversely affected by trendy new companies entering the market and offering a new brand of snake oil to change the way everyone does business.

The ’CAM agnostic’ approach of recent years requires independent simulation and verification of the CAM output. Simulation is now part of every CAM system, but the trend is towards CAM systems with interfaces to CGTech’s VERICUT. Many CAM vendors have their own verification capability, but the industry was sceptical and resisted toolpath verifiers that came from the same software suite that generated the toolpath. In addition to the established interfaces (to CATIA V4 and V5, Siemens PLM, PTC, EdgeCAM and MasterCAM) over the past couple of years CGTech has added interfaces to GibbsCAM and Missler TopSolid CAM. Delcam has written an interface for PowerMill while Open Mind wrote one for hyperMILL.

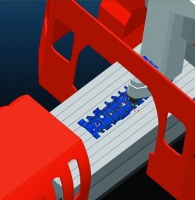

VERICUT simulates all types of CNC machine tools, including those from manufacturers such as Mazak, Makino, Matsuura, Hermle, DMG, DIXI, Mori Seiki and Chiron. In addition to verifying CNC part programs, it also optimises them to save time and produce higher-quality surface finishes. It also reduces scrap loss and rework.

MachineSim, a development from Open Mind Technologies, takes this notion one step further by letting the user verify selected machining processes without tying up valuable machine time.

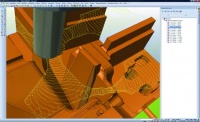

MachineSim is like other simulators in that it lets the user run the machining process virtually, while at the same time dynamically rotating and zooming the 3D model of the machine and workpiece (including jigs and fixtures) to check for any gouging or collisions. The simulation can be fast-forwarded, paused and rewound, which helps to build up the user’s confidence of running complex parts on machines that can run at extremely high speeds.

The key element in this is hyperMILL’s patented collision-avoidance technology – this automatically avoids collisions and means no further action is necessary, saving considerable time and effort.

Up until now, the CAM system was exclusively used for programming individual machining steps. With its job-based workflow, Open Mind Technologies was an early pioneer of job list-oriented CAM programming. With the latest version of hyperMILL, this approach was further developed to create CAM process planning.

Developments at Siemens PLM have involved part manufacturing solutions that connect planning to production. This is made feasible by the combination of Siemens PLM Software and Siemens Motion Control Systems (MC). PLM provides the (virtual) planning side of the solution and MC provides the production (real) side. Overall efficiency in part manufacturing has been improved, with enhanced utilisation of manufacturing resources such as machine tools and controllers.

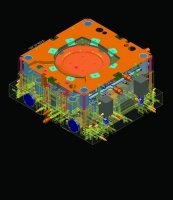

Siemens PLM introduced a new set of technology to drive its feature-based machining in NX 6. A wide range of prismatic features can be now be recognised from any geometry. The machining method is generated on the fly – an engine assembles each operation step based on selection logic managed in a machining knowledge database. The benefit is that this significantly reduces the number of stored/retained machining-method templates.

In recent years, advances in machining strategies have been largely associated with five-axis technology. With regards to material removal, only isolated adaptations of the machining strategies took place in CAM in conventional 2D and 3D machining in order to allow for further improvements in tools.

On the other hand, auxiliary processing times arising from infeed and clearance movements provide enormous possibilities for time savings and therefore cost savings, even if they occur with high feed rates and rapid movements. In order to reduce these auxiliary processing times, the user has to use well thought-out reliable technologies that set the course for decreasing machine running times, even during CAM programming.

Companies are constantly looking to make further cost savings in their machining. But most of the technology-driven cost savings have long since been exhausted. Focus is now shifting to integrating the CNC into manufacturing planning processes to gain efficiencies.

Design essentials

The key facts to take away from this article

» VERICUT verifies and optimises CNC programs

» MachineSim also verifies machining processes

» Siemens PLM has focused on connecting planning to production

» It combined its PLM and motion control (MC) systems: the PLM system plans while the MC one deals with production

What’snew

Design software

» Making the vericut

VERICUT 7 speeds up the development, analysis, inspection and documentation of the CNC programming and machining process. Its modified user interface has a more obvious sequence to the most common user actions and there is also a top-down flow through the user’s graphical tree layout, with context-sensitive choices that appear as the user moves along in the NC program simulation. It also features improved system and graphics performance for a better and faster system.

www.cgtech.com

» Open wide

Open Mind hyperDENT facilitates production of dental crowns and bridges. It is an open and automated programming system that accepts different data formats and accommodates different milling machines and raw materials from several manufacturers. It features intuitive user interfaces and practical functions for reliable and timesaving programming. Open Mind hyperDENT has many machining strategies tasks – from 3D milling to sophisticated five-axis programming – for reliable machining of complex dental structures. An optional workflow manager automatically guides users to the finished NC program.

www.openmind-tech.com

» Three-axis machining advances

NX-CAM Version 6, from Siemens PLM, features advances in three-axis machining and feature-based automation. These include cutting strategies for curve/edge and 3D-profile cutting, optimised corner-rounding techniques, smoother finish cuts through specialised point distribution, and new toolpath editing/dividing tools. Siemens PLM Software offers many of these facilities in CAM Express as part of its Velocity Series. The system is easy to deploy, learn and use, with the industry’s best practices pre-configured and built in to standard processes.

www.plm.automation.siemens.com

» Complete machining software

PTC’s Pro/ENGINEER Complete Machining creates all types of programs for CNC machines used in production environments. It lets the user directly machine simple or complex product geometries with NC toolpaths optimised for manufacturing. It has the capabilities of Pro/ENGINEER Production Machining, extended to multi-axis machining, full NC programming capabilities and tool libraries. Complete Machining improves tool design and manufacturing. It features 2.5 to five-axis milling, multi-axis turning and mill/turn (live tooling), and four-axis wire EDM. As part of an integrated CAD/CAM solution, no data translation is required and it cuts time to market with associative tool-path updates to design changes.

www.ptc.com

» Parasolid Toolmaker

Delcam’s Toolmaker tooling-design software now incorporates the Parasolid modelling kernel from Siemens PLM Software. It also features catalogues from all leading global mould-component suppliers. Parasolid reinforces the solid modelling and assembly modelling capabilities of Toolmaker and complements its surface-modelling capabilities. The two technologies provide benefits for toolmakers that use imported product-design data as the basis for their tooling designs.

www.delcam.com

Red Bull makes hydrogen fuel cell play with AVL

Many a true word spoken in jest. "<i><b>Surely EVs are the best solution for motor sports</b></i>?" Naturally, two electric motors demonstrably...