Ever since the financial crisis took hold in 2007, politicians have been shouting over each other for a ’rebalancing of the economy’ away from financial engineering towards real engineering and high-value manufacturing.

This of course misses the point that the UK was already punching above its weight in manufacturing, with unique expertise in particular areas. Nevertheless the ensuing credit problem risks losing this position and missing out on valuable opportunities with fledgling technologies, as companies scale back on research and development.

Partly in response to this threat, the government has created the High Value Manufacturing Technology and Innovation Centre (HVM-TIC) a consortium of seven centres from across the UK (see panel one).

The newest of these and arguably the most ambitious in scope is the National Composites Centre (NCC) in Bristol. It will cater for a range of potential partners, from individual university research groups to global corporations, across different industrial sectors. As a corollary it also aims to drive down carbon emissions through the widescale uptake of composite components.

“If companies have an idea about how to improve a process, they can come here”

PETER CHIVERS, NCC CHIEF EXECUTIVE

’One of the key reasons for the growth of composites is that you can make things lighter, and for anything that moves if you make it lighter you need less energy to make it move, to make it go round corners or stop it’s pretty fundamental Newtonian laws,’ said Peter Chivers, NCC chief executive.

Of course, the UK has decades of composite experience in specialist aerospace components and performance cars McLaren being the first company to use the technology in Formula 1 motorsport back in 1981. But this expertise has tended to be somewhat isolated and focused on particular processes or single components. Some believe that has prevented the transfer of technologies and the emergence of a unified ’UK composites industry’.

’Collaborative problem solving is very powerful. Bringing together people making luxury yachts, with the automotive sector, with aerospace they’re all in some ways trying to solve the same problems. You’ve got an opportunity [at the NCC] for them to say: “hang on a minute I’ve solved something like that over here.” They’re non-competing, it’s neutral territory.’

The NCC will be equipped with all the latest kit for building and testing composites, and in this particular context size matters (see panel two).

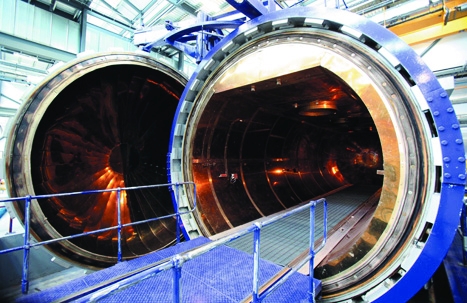

For example, the 8, 500m2 space has a 90-tonne autoclave for curing parts up to 10 x 3m the idea being that experimental technologies can be tested out at full industrial scale without the large capital risk, on a ’power-by-the-hour’ basis.

A professor of materials science might come and see how a promising new resin performs as part of a small component, while an SME might test out a new, more efficient, production process at full tilt.

As Chivers puts it: ’helping cross what some people call the valley of death, where so many technologies die.

’Obviously [companies have] got to set up a production line at some point and there’ll be a capital cost then, but at that point they’ll understand so much more about what it is they’re trying to make, what the processes are and they’ll spend that capital much more wisely.’

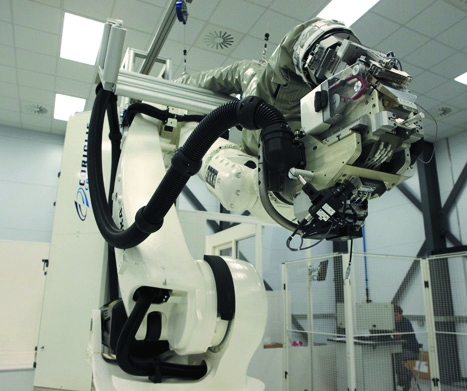

That applies to some of the larger NCC partners too. Aerospace company GKN has led the way in composite manufacture with a new state-of-the-art production facility in Filton, north of Bristol. It houses a robotic machine that precisely lays down fibres pre-impregnated with resin, thereby bypassing a previously time and labour-intensive process and increasing repeatability. The factory is currently producing the wings for the A350 XWB lightweight composite airliner (Airbus).

So why has GKN now forked out £2.5m for a slightly better machine at the NCC?

’That equipment they have [at Filton] will be running flat-out on production,’ said Chivers. ’If [companies] have an idea about how to improve the process or subtly change the product, they can come here. They don’t have to take a piece of equipment that’s earning money for them out of service for an undetermined period of time while they experiment with it.’

The work the NCC does could engender a shift in the way we think about composite manufacture

The most recent addition to the NCC family is Umeco, one of Europe’s largest companies focused solely on composites, with interests across aerospace, defence, wind power, sports and the automotive industry. The company hit the headlines recently when its Advanced Composites Group secured the contract to build the body for the Bloodhound land speed record bid.

But as far as the motor industry goes Chivers sees composites being used not just in small-volume hypercars, but in regular production models. It is simply a matter of confidence, perception and fashions, he says.

’You look back and think how automotive technologies have set the message for lots of territories how it went from the basic capabilities of the vehicle, then the Japanese came along and you had to have lots of goodies on your car, then safety with the NCAP rating was critical, now fuel economy is a major driver. Is lightweighting going to be the next one? I hope so.’

The NCC has a large team of dedicated engineers, technicians and designers to not only assist the partners and clients, but to take an active role in projects, if needed. Chivers says that the team he has assembled already has substantial expertise, but the unique experience it will gain in the coming years will make it ’truly world class’ a repository of composites knowledge to draw upon. The work the NCC does could even engender a paradigm shift in the way we think about composite manufacture, eventually making current components look almost primitive.

’There are still too many places where we’re making “black metal solutions”; we’re designing things in composites in the same way we used to make them in metal, but it’s fundamentally a different material in terms of properties and behaviour and manufacturing processes.

’If you make it like you used to make metallics you build in all sorts of weakness you don’t need to have there. But also you don’t take advantage of the fact that you can make things you couldn’t make in metallic materials one-piece integrated solutions with the features embodied in the composite.’

To this end he points towards the construction industry. Bristol University is looking at building composite footbridges for railways and motorways, the advantage being that it doesn’t need a central pier and is light enough to be handled as a whole structure. Cost seen as a limiting factor for composite use is also potentially reduced.

’People see composites as being a lot more expensive and for a part-for-part basis you’ll probably never compete with metallics. But if you start to take a much more holistic view and think about integrating parts into one subassembly and even embedding other functionality into the component then you start to create a much higher value single component out of one process.’

in depth

cutting-edge

The NCC is set to use the latest kit for the testing of composites

Management: University of Bristol and South West Regional Development Agency (RDA)

’Tier-one’ members: Umeco, AgustaWestland, Airbus, GKN, Rolls-Royce, Vestas

Facility: 8,500m2 space houses workshops, offices, meeting rooms, designed to BREEAM excellent environmental rating

Key equipment: Double-diaphragm forming machine (15 x 3m capability); automated fibre placement machine with twin robotic heads; 90-tonne autoclave (10 x 3m capability); non-destructive ultrasonic testing facility; and materials laboratory

in depth

the consortium

A group of seven centres will make up the government’s HVM-TIC

Investment funding: £140m over six years with an additional £33m from the Technology Strategy Board

Centres: Advanced Manufacturing Research Centre (Rotherham); Nuclear Advanced Manufacturing Research Centre (Rotherham); Manufacturing Technology Centre (Coventry); Advanced Forming Research Centre (University of Strathclyde); National Composite Centre (University of Bristol); Centre for Process Innovation (Wilton & Sedgefield); Warwick Manufacturing Group

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...