Last week MWP Advanced Manufacturing reported on how Britain’s car manufacturers are experiencing increased levels of output and higher productivity.

A new report out today paints a similarly bright picture, with Britain’ regions the being scrutinised in relation to business confidence, export success, output, productivity and employment.

Regional Manufacturing Outlook is an annual report from EEF and its main findings include:

- West Midlands manufacturers are the most confident in the UK, with manufacturers in Wales and the North East at the other end of the confidence spectrum.

- London and South East accounts for 25.4% of the UK’s manufactured exports, which represents the biggest contribution by any single region

- The EU is the biggest export market for manufacturers in every region of the UK, accounting for between 40% (West Midlands) and 59% (South West) of manufactured exports

- East Midlands manufacturers contribute the most to regional output (16.3%) but London and South East manufacturers account for just under a fifth (18%) of total UK manufacturing output

- UK manufacturing employs 2.6 million people but the importance of manufacturing to local employment varies from 6% of the workforce in London and the South East through to 15% in the East Midlands.

The full Regional Manufacturing Outlook can be downloaded here: http://www.eef.org.uk/resources-and-knowledge/research-and-intelligence/industry-reports/eef-regional-manufacturing-outlook

Lee Hopley, EEF’s chief economist commented that manufacturers are overcoming challenges and by doing so are gaining recognition in key markets for their “ingenuity, creativity and skills”.

“It is also clear, however, that some of the obstacles facing UK manufacturers cannot be overcome by grit and determination alone,” Hopley cautions. “Policy makers have a critical role to play and must focus on ensuring that support for exporters, innovators and investors is well-targeted and hits the sweet spot.”

The West Midlands is often a valuable source of material for MWP Advanced Manufacturing, so I put the feelers out to gauge whether the sentiment contained in today’s report is reflected in the region.

SMT Developments is an electronic assembly specialist based in Warwick and the company’s John Rowley told The Engineer: “Business is very buoyant at the moment, with good quality quotation requests and a general sense of optimism across the markets we operate in, including automotive, LED and specialist electronics.

“Our spend on capital equipment is higher than ever, as we recongise the importance of building on this momentum with the installation of technology that will improve quality, speed of turnaround and increase capacity. We’ve also taken on more people to cope with new contract wins and the workforce currently stands at 37 people.

“However, the outlook isn’t all sweetness and light. There are still issues around the ability to employ skilled staff and this threatens to stifle productivity.”

Michael Collins, sales and marketing director at Penso added: “Policy makers have a critical role to play and must focus on ensuring that support for exporters, innovators and investors is well-targeted.

“At Penso with support of AMSCI [Advanced Manufacturing Supply Chain Initiative] and Innovate we have advanced our learning and business successfully with support from these government backed initiatives.

“R&D Tax credits are superb for a business like Penso as we are consistently researching and developing new idea to take to production to assist OEM’s with C02 reduction requirements.”

Aiming to do their bit for productivity is Senseye, whose online tool promises to cut operations and maintenance costs for manufacturers.

The company’s founders have backgrounds in aerospace and defence where for over 20 years complex condition monitoring systems have been accurately predicting variables including engine performance, component wear rates, and safety failures.

These predictive tools come at a cost and require a degree of expert input, which is why Senseye is “giving the manufacturing and machines markets predictive technology that they can use without a background in engineering or data analytics and for less than the cost of a small pump.”

Dr Simon Kampa, co-founder of Senseye, has been to touch with a request that some of you might be able to help with.

He says: “As the web-based product is still in development, we are hoping to start off by attracting manufacturing companies (and companies that operate machinery) to join our free trial so that we can start getting their data and feedback to help us improve the product – whilst saving them money and making their busy lives easier!”

Interested parties should visit the trial sign-up page.

Some will mourn whilst some may marvel at this week’s next event, which literally brings the curtain down on one of E.ON’s power stations.

This coming Sunday (August 2) sees the demolition of boiler houses and boilers of Grain Power Station in Kent.

Grain closed in December 2012 as it was no longer economically viable but, similar to other power stations in Britain, the EU’s Large Combustion Plant Directive would have required it to close after generating for 20,000 hours from 1 January 2008, or before the end of 2015 depending on which milestone came first.

At the time of closure the power station was capable of producing around 1,320MW and this Sunday the boiler houses, and three of the five oil-fired boilers integral to this rating, will be demolition via controlled explosion.

During the demolition approximately 20,000 tonnes of steel will be brought to the ground, which E.ON say will be one of three demolition milestones at Grain before the 244m chimney is demolished during 2016.

Today marks the start of the Institution of Engineering and Technology’s (IET) inaugural Engineering Open House Day with events taking place to alert youngsters to engineering careers.

Part of IET’s Engineer a Better World campaign, a number of venues and businesses are opening their doors to reveal how engineers are integral to the running of their operations.

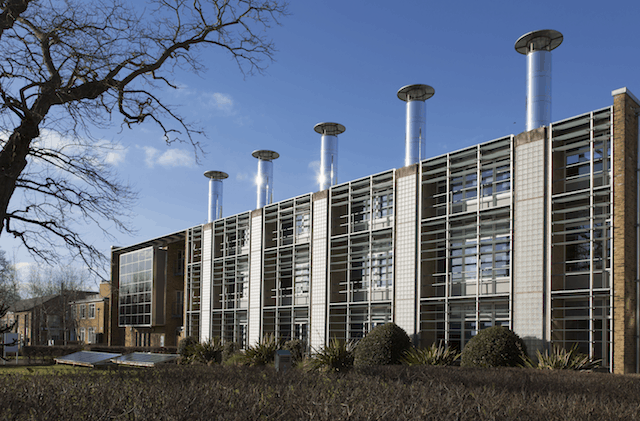

Participants include ITN Studios, the Royal Opera House in London, Soho House (part of Birmingham Science Museum) in Birmingham, the Everyman Theatre in Liverpool and the Building Research Establishment (BRE) in Hertfordshire (pictured above).

IET say in publicity material that “all of the organisations involved will give young people and their parents the chance to explore the variety of stimulating and creative careers in modern engineering by putting on tours, workshops and talks from inspirational engineers.

“Additionally, guests will have the chance to ask engineers about their career experiences, what they actually do and why the industry appealed to them.”

To find out more about the events on offer and how to register for a place at the IET’s Engineering Open House Day, please visit: http://www.engineer-a-better-world.org/engineering-open-house-day.

In a similar vein of betterment and engagement, a number of students from the UK and EU are taking part in a week-long series of events and activities designed to give them a taste of university life and an insight into engineering careers.

A total of 74 A-Level students from across the UK and beyond are taking part in Southampton University’s Electronics and Computer Science (ECS) annual summer school, which includes lectures covering varied aspects of ECS, from electronic and electrical engineering to computer science and software engineering. Participants will also be given the opportunity to tour the University’s specialist facilities, including the Tony Davies High Voltage Laboratory and the Southampton Nanofabrication Centre.

Sponsored by JP Morgan and Imagination Technologies, the summer school’s links with industry are helping participants to better understand career options for ECS graduates. Next year’s ECS residential course will run from 25 to 29July 2016. To find out more, or for any enquiries, visit www.summerschool.ecs.soton.ac.uk or follow updates on Twitter using #ecssummerschool.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.