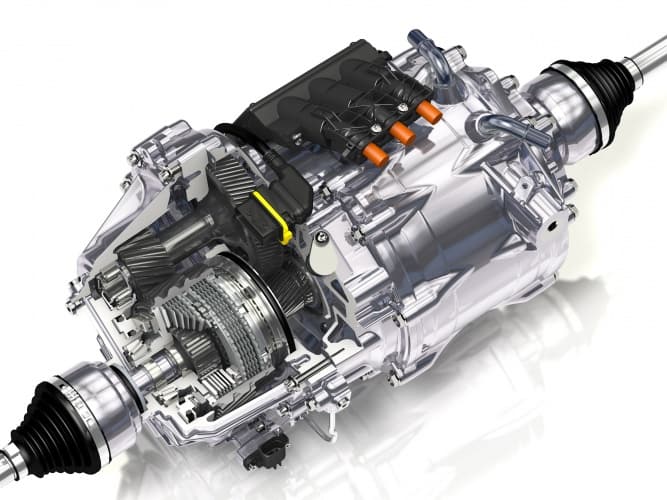

Recently demonstrated to The Engineer at the firm’s Wintertest proving ground in Arjeplog, Northern Sweden, the so-called ‘e-Twinster’ system is a plug-in hybrid module claimed to make it simpler for vehicle platforms to offer electric all-wheel drive and torque vectoring.

The technology combines the firm’s existing eAxle technology - already used on plug-in hybrids including the Volvo XC90 T8, and BMW i8 - with the twin-clutch torque vectoring technology featured in both the Ford Focus RS and Range Rover Evoque.

The technology was demonstrated on a prototype version of the Volvo XC90 T8 chosen partly because GKN already supplies the vehicle’s electric motor module. In the vehicle, a 60kW, 240Nm electric motor drives an electric axle with a transmission ratio of 1:10. A dual-clutch Twinster system then vectors the resulting 2,400Nm of torque between the rear wheels.

Presented alongside a conventional version of the car, the prototype vehicle demonstrated significantly superior dynamic response and handling on the frozen lake at the heart of the firm’s winter test facility.

GKN Automotive’s technology chief Peter Moelgg said: “We believe…our system represents the next step forward for the industry: a production-ready way to create higher performance hybrids that are more rewarding to drive.”

The company predicts that by 2025 up to 50% of all vehicles will have some level of electrification, with a greater proportion of hybrids’ power delivered from the electric motor. While current mass-production vehicle platforms can only draw around 30% of their energy from a battery, GKN claims that small, powerful, torque-vectoring electric axles could deliver 60-70% of the power in future vehicles.

According to the company several major automakers have already expressed an interest in the system, and it could be integrated into a vehicle platform for production within the next three years.

Swiss geoengineering start-up targets methane removal

Several rather dubious statistics in this report. IF methane had 120× the thermal effect of CO2 that would be TWO orders of magnitude. Two is not...