‘This technology could eventually lead to wearable “smart clothes” that can power hand-held electronics through ordinary body movements,’ said Liwei Lin, UC Berkeley professor of mechanical engineering and head of the international research team that developed the fibre nanogenerators.

The nanofibres are made from organic polyvinylidene fluoride (PVDF), making them flexible and relatively easy and economical to manufacture.

‘Because the nanofibres are so small, we could weave them right into clothes with no perceptible change in comfort for the user,’ added Lin, who is also co-director of the Berkeley Sensor and Actuator Center at UC Berkeley.

Other research teams have previously made nanogenerators out of inorganic semiconducting materials, such as zinc oxide or barium titanate.

‘Inorganic nanogenerators — in contrast to the organic nanogenerators we created — are more brittle and harder to grow in significant quantities,’ Lin said.

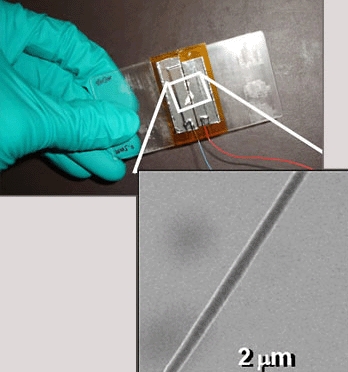

The nanogenerators have diameters as small as 500 nanometres.

The researchers repeatedly tugged the nanofibres, generating electrical outputs ranging from five to 30 millivolts and 0.5 to three nanoamps.

Furthermore, the researchers report no noticeable degradation after stretching and releasing the nanofibres for 100 minutes at a frequency of 0.5Hz.

Lin’s team at UC Berkeley are said to have pioneered the near-field electrospinning technique used to create and position the polymeric nanogenerators 50 micrometres apart in a grid pattern.

The technology enables greater control of the placement of the nanofibres onto a surface, allowing researchers to properly align the fibre nanogenerators so that positive and negative poles are on opposite ends.

The researchers demonstrated energy conversion efficiencies as high as 21.8 per cent, with an average of 12.5 per cent.

‘Surprisingly, the energy-efficiency ratings of the nanofibres are much greater than the 0.5 to four per cent achieved in typical power generators made from experimental piezoelectric PVDF thin films and the 6.8 per cent in nanogenerators made from zinc-oxide fine wires,’ said researcher Chieh Chang.

‘We think the efficiency could be raised further,’ Lin continued.

‘For our preliminary results, we see a trend that the smaller the fibre we have, the better the energy efficiency. We don’t know what the limit is.’

The fibre nanogenerators are described in this month’s issue of Nano Letters.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...