Industrial Biotechnology (IB) is one of the rising stars of the UK’s science and engineering industries. It has the potential to both address global challenges and change the engineering and manufacturing industries for the better. In doing so, it could contribute up to £12 billion to the UK economy by 2025.

But like many fledgling industries, it has some way to go, both on the technical and the business side. In particular, it is not well understood by those outside the sector, which is a problem for an industry with so much downstream potential. If IB is to reach this potential, it needs to take a greater role within the wider engineering and manufacturing industries.

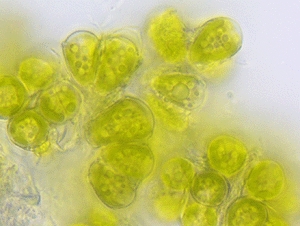

Industrial Biotechnology is defined as the use of biological organisms or substances to produce materials, chemicals and energy for industrial purposes. By manipulating plants and organic materials, we can create new effects unachievable with conventional chemistry, and replace current materials and processes with improved and more environmentally friendly ones.

The opportunities are enormous. A 2007 Paper (En route to the knowledge-based bio economy) suggested that by 2030, one third of chemicals and materials would be based on biological sources. This has big implications for other industries.

Fibre based materials, for example, have a wide range of applications. They are sparking interest in sectors such as automotive - where fuel saving through weight reduction and ease of disposal of vehicles is important - for parts ranging from damping and insulation to wheel arches and door trim panels.

Bio plastics could eliminate environmental nightmares such as plastic bags by making them biodegradable. One company we have worked with, Innovia Films, has produced biodegradable materials which, among other things, have replaced the wrappers for Quality Street.

One of the most exciting and rapidly growing areas is biofuel. This could replace a substantial chunk of oil based fuels having a huge impact on all sorts of areas of engineering. Petroleum giants are extremely interested in new more sustainable fuels to diversify their output away from a reliance on oil and are investing big money in developing technologies to make this viable on mass scales.

Demand for biofuels and materials are likely to grow in the coming years. How much so will depend in part on the cost of fossil fuels – but with depleting resources, prices are likely to rise over the long term. This, coupled with ever growing environmental concerns, makes biotechnology an exciting prospect.

“Our chemicals industry has moved away from oil and chlorine towards functional materials and more high end chemical applications

The good news is that the UK is well placed to be a world leader in this area. We have a top three position in research and technology for biosciences and biotechnology and a top ten position in the commercial size of our chemical process manufacturing base. Our chemicals industry has moved away from oil and chlorine towards functional materials and more high end chemical applications. We have the expertise in gene codes to produce the materials people are looking for and the right biochemists to develop useful businesses.

But we are not there yet. The industry still has a number of barriers to overcome.

The instinct of chemists is to try and make biological alternatives to the chemicals we have always used. Plants, unlike chemicals, are by their nature unspecific, so creating like-for-like replacements can be difficult. In many cases, isolating the useful molecules requires separation from vast amounts of waste product. For the future of the industry, we need to look at either using biosystems in an unseperated form, or find more efficient means of separation. This will be a job for our more imaginative engineers.

“Much of IB’s value is in its ability to improve other industries. To succeed it needs to engage with them more closely

One of the biggest challenges isn’t the chemistry itself but the disconnect between industries. Much of IB’s value is in its ability to improve other industries. To succeed it needs to engage with them more closely. There is as yet little understanding in industries such as engineering and manufacturing of what IB can offer. Equally problematic is that many of those working in IB don’t fully understand the needs that chemistry using industries face.

It is vitally important that we get IB talking to downstream industries so that both sides understand the huge potential that can be gained from IB in providing better materials, reducing fuel costs and emissions, improving production processes and identifying new areas which haven’t even been considered yet.

IB has huge potential for engineering industries in a variety of ways. But it needs engineers to engage with it to solve problems and take advantage of its solutions.

There are many ways to get involved with Industrial biotechnology through the Chemistry Innovation Knowledge Transfer Network, of which Mr Armstrong is chairman, and the Industrial Biotechnology Leadership Forum, which is chaired by Mr Shott

Red Bull makes hydrogen fuel cell play with AVL

Many a true word spoken in jest. "<i><b>Surely EVs are the best solution for motor sports</b></i>?" Naturally, two electric motors demonstrably...