They believe that devices based on their technology could be faster and more accurate than current polarisation measurement techniques, which use devices based on silicon technology.

Polarisation is determined by the direction in which the electrical component of the electromagnetic field we perceive as light oscillates. Plane-polarised light – in which the field of a whole light-stream oscillates in the same direction - has many uses; because its polarisation affects how it bounces off objects, it can show up disturbed ground when searching or buried objects and can be used in atmospheric monitoring and medicine, for example.

The North Carolina team, led by Michael Kudenov, used a polymer known as P3HT:PCBM in their research; when this polymer is stretched, the backbones of the polymer chains all orient in one direction, and it absorbs polarised light whose oscillation is parallel to that direction and produces a photoelectric current.

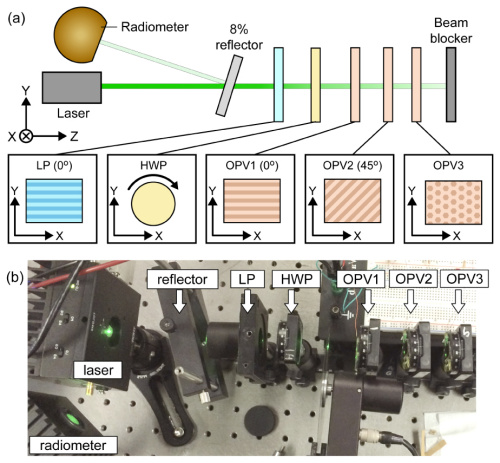

Kudenov’s team, which explains its results in the journal Optical Express, made semi-transparent polymer films and placed them into a stack of materials with transparent gold film and indium tin oxide, stacked them together so that their alignment directions were all different.

This means that when a sample of light passes through the stack, each film absorbs the light in the sample that is polarised in the corresponding direction and produces a photocurrent proportional to the light absorbed.

The rest of the sample continues to the next layer and so on. Analysing the currents from each film using a specifically designed algorithm gives a measurement of how the original sample was polarised, even though the last film in the stack has unoriented polymer chains.

"Most types of polarised light, particularly in natural environments, have a large linear polarisation signature," Kudenov said. "And three measurements are sufficient for us to calculate the state of linear polarisation in a light sample."

Conventional polarisation detectors, based on photovoltaic silicon, have to sample light at different times, or at the same time but at multiple points, which can affect accuracy. The NC State team’s prototype device, tested using laser light of known polarisation, does it all in one measurement and produced errors as low as 1.2 per cent.

"It's a good starting point, though not as good as the best polarisation detectors currently on the market," Kudenov said. "However, we're optimistic that we'll be able to reduce the measurement error significantly as we improve the device's design. We're really just getting started."

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?