Imagine an industry that has defied the worst economic downturn in living memory and continued to grow; an industry that designs and manufactures the most advanced pieces of some of the world’s most-talked-about feats of engineering; an industry with a bright present and a plan for the future; and an industry that’s internationally recognised as being one of the best in the world. While this might sound to some like a frustrating blueprint for everything the UK has lost, its buoyant aerospace sector ticks all of these boxes and many more.

In this feature we’ve detailed some of the UK aerospace sector’s many success stories: from its rapidly growing expertise in the space industry, to its established position as one of the world’s leading designers and manufacturers of everything you need to make an aircraft.

Commercial aircraft

Although the UK no longer builds complete passenger aircraft it retains the skills and capabilities to design and manufacture almost all of the key components: from fuel systems and landing gear, through to wings, fuselages, flight control surfaces, nacelles and jet engines.

And whilst the lack of an entirely domestically produced civil airliner is viewed by some as a sign of an industry in decline, the truth is that the UK boasts the second largest civil aerospace industry in the world. Exporting 75% of what it produces, and generating almost £12bn in revenues the sector enjoys a 17 % market share, and is second only to the US.

over a quarter of the value of Boeing’s 787 “Dreamliner” comes from UK manufacturers

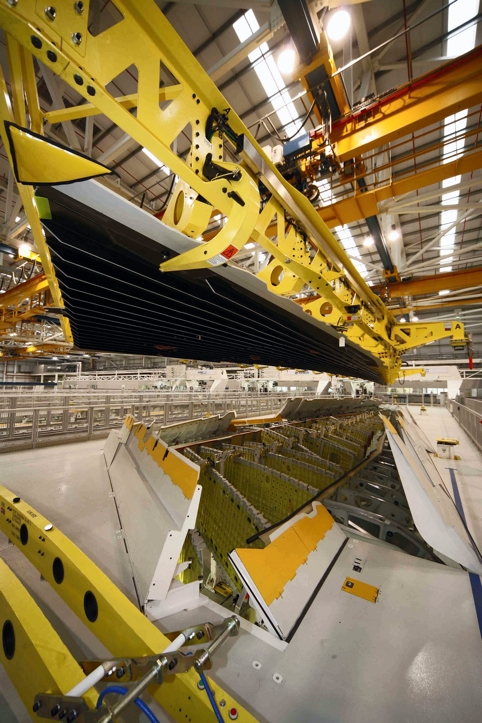

UK firms are at the forefront of industry’s quest to make civil aircraft ever more fuel efficient and have had significant involvement in the most prominent new civil aircraft of recent times. The wings for the Airbus A380 and the A350 XWB are designed and manufactured at Airbus UK’s world-leading Broughton facility, whilst over a quarter of the value of Boeing’s 787 “Dreamliner” comes from UK manufacturers including Eaton (fuel subsystem pumps), Messier-Bugatti-Dowty (the landing gear) and Rolls-Royce (the engines)

Other key names include GKN Aerospace – an expert in metallic and composite aerostructures that’s involved in almost every civil and military fixed and rotary wing aircraft in production and development today, and Bombardier - the world’s third largest airline manufacturer, which built the wings for its new C-Series aircraft at its Northern Ireland manufacturing facility.

Prospects for the future look good. According to the Global Aerospace Outlook 2013, a recent report commissioned by industry trade body ADS Group, expected demand over the next 15 years for 27,000 new large civil airliners and 40,000 rotor aircraft could translate into UK orders worth £474bn.

The challenge for industry now is to continue to play to its strengths, to innovate and to invest in the skills that will help the sector remain competitive. The establishment of the aerospace growth partnership - a joint collaboration between industry and government – is a welcome move towards a coherent vision for the years ahead.

Supply Chain

By some estimates, the UK has around 3,000 companies that are involved in the aerospace supply chain employing some 230,000 people directly and indirectly, ranging from very large companies such as Rolls-Royce to small businesses making very specialised components.

Developing the supply chain is a matter of concern for the government, with a £90m initiative unveiled by the Department of Business, Innovation and Skills this summer; £50m to fund collaborative R&D projects to develop innovative technologies and £40m to address skills shortages. ‘The National Aerospace Technology Exploitation Programme will embed important new technology and capability into the UK supply chain,’ commented Graham Chisnell, deputy chairman of the industry association ADS. ‘Helping smaller companies to invest and develop new technologies will help us achieve long-term competitive advantage.’

Martin-Baker, the world’s leading manufacturer of ejector seats, is based in the UK

Examples of aerospace supply-chain companies include Gloucester-based Messier-Bugatti-Dowty (actually part of the French aerospace conglomerate Safran), which produces landing gear for most of the world’s large commercial airliners. MBD is supported, as are many companies involved in the metal components of aircraft, by the Advanced Manufacturing Research Centre at Sheffield University, which is co-funded by Boeing — this centre helped MBD to develop machining processes to work titanium spars used in the landing gear of the Boeing 787 Dreamliner.

In the defence aerospace supply chain, the world’s leading manufacturer of ejector seats is based in the UK. Martin-Baker, which developed the first ejector seats in the mid-1940s, and now produces ejector seats for fixed-wing aircraft and crashworthy seating for helicopters from its headquarters near Uxbridge.

Military Aircraft

Of all areas of UK aerospace, the defence sector has perhaps been characterised as the most enfeebled. And cuts to government spending in recent years have done little to dispel perceptions that an industry responsible for iconic aircraft like the Spitfire and Harrier Jump Jet is in decline.

There are, it’s true to say, genuine concerns in some quarters that the sector has become overly reliant on the production of components designed elsewhere. Writing in The Engineer last year, Professor Keith Haywood of The Royal Aeronautical Society warned that the UK had become overly reliant on production work on overseas projects and that its established sovereign expertise is at risk without a major domestic aircraft project.

But for now at least, the UK remains a potent force with defence aerospace providing the bulk of UK military export sales and contributing £35 billion a year to the economy.

The UK - primarily through BAE Systems - plays a critical role on some of the world’s biggest defence aerospace projects.

The company makes large sections of the Typhoon Eurofighter at its sub-assembly plant in Salmesbury and assembles the aircraft for the RAF at its Warton Plant, near Preston. It is also a principal subcontractor on the F35 Joint Strike Fighter - the world’s largest single defence project - for which it designs and manufactures a range of components including the aft fuselage, vertical and horizontal tail and wing tips and fuel system. As well as this it manufactures the Hawk, the world’s most successful jet training aircraft - at its Warton plant.

Other major players include Airbus UK - which manufactures the wings for the A400m military transporter, Rolls Royce, whose engines power around a quarter of the word’s military fleet and Agusta Westland which designs and manufactures complete helicopters in the UK.

UAVs

Although endlessly controversial, unmanned aircraft systems (UAS) — ‘drones’ to the public — are a crucial sector for the aerospace industry. The distinction between a UAV (unmanned autonomous/aerial vehicle) and a UAS is that the UAV is just the flying part, while UAS refers to the entire system, including the ground-based technology that’s vital for monitoring and setting mission parameters for the aircraft.

The UK is an important centre for UAS development, particularly because, as single countries are finding it increasingly difficult to fund the development of advanced piloted fighter aircraft, UAS technology is seen as part of ‘sovereignty’ — the ability of the country to produce the essential defence equipment to ensure its own security without the need to depend on other nations. They also embody all the skills needed to design and build entire aircraft: particularly important when aircraft are being built component by component in different countries and assembled elsewhere.

ASTRAEA is developing all the systems necessary to fly a UAV in occupied civil airspace

The main player in UAS in the UK is, unsurprisingly, BAE Systems, which produces the MANTIS twin-engined UAV and has development programmes for the TARANIS stealthy unmanned combat aircraft, which is projected to enter flight trials this year, and the DEMON flapless aircraft, which controls its trajectory with jets of air blown over the edges of its wings. But the project which best illustrates the reach of UAS in the UK aerospace sector is ASTRAEA (autonomous systems technology related airborne evaluation and assessment), which is developing all the systems necessary to fly a UAV in occupied civil airspace, including the ability to sense and avoid other aircraft and to navigate around dangerous weather systems. Led by BAE, the ASTRAEA consortium includes software company AOS, EADS’ defence arm Cassidian, Thales, QinetiQ and Cobham. The technology has been installed on a flying test-bed, which although piloted for safety reasons, can be operated as a UAV; it is currently undergoing flight trials in UK airspace.

Research base

The UK’s aerospace sector is supported by a widespread research base, with many universities contributing towards study of the fundamentals of flight and development of new technologies. Notable sites include the National Composites Centre at Bristol University, which has been heavily involved in developing composite wings for civil aircraft such as the Airbus A350; the Institute for Aerospace Technology at Nottingham University: the Whittle Centre at the University of Cambridge, which focuses on jet-engine technologies; and the Department for Aerospace Engineering at the University of Cranfield, which was BAE Systems’ partner in developing the flapless DEMON UAV.

Cranfield is set to further its aerospace credentials with an Aerospace Technology Institute (ATI), which will open its doors at Cranfield Technology Park in December. The ATI, which will develop academic-industrial collaborative projects worth some £2bn, will have a core team of 30 staff, although the projects it develops will be carried out at centres across the UK including at the various High-Value Manufacturing Catapult centres, for which aerospace is a key sector.

The ATI is focusing on work across four streams: aerodynamics, propulsion, aerostructures and advanced systems. In an early ‘Grand Challenge’, the centre will direct research into quieter, more energy-efficient aircraft; parts of this project include a project called HARMONY, in conjunction with Rolls-Royce, Short Brothers and the universities of Southampton and Cambridge. This is developing prediction tools for unsteady airflow and the acoustics associated with it, for airframes and engines destined to go into service after 2020, when Advisory Council for Aeronautics Research in Europe targets stipulate, for example, a 50 per cent reduction of CO2 emissions.

Space

Possibly the least-known part of the aerospace industry, the space sector is also the fastest growing. Worth £9.1bn in 2011 and employing 29,000 people, it is growing at a rate of some 7.5 per cent annually, according to its umbrella organisation, the UK Space Agency. Government strategy is for space to be a £40bn business for the UK by 2030, capturing a 10 per cent share of the $250bn world market for commercial space technology — up from about six per cent in 2007 and with a target of 100,000 new jobs.

The UK’s contribution to space centres around communications satellites, very much the workhorses of Low Earth Orbit. Although the UK is heavily involved in space science and discovery missions, a series of historical decisions, including not developing launcher technologies in the early 1960s and opting out of manned mission technologies in the 1980s, contrived to keep the UK out of the limelight of the most visible, high-profile aspects of space.

Both of these might be changing, however, with the much-discussed development of the Skylon spaceplane and the UK’s involvement in developing the service module for NASA’s Orion capsule, the manned successor to the Space Shuttle.

Much of the UK’s space industry is centred around EADS Astrium, based in Stevenage and Portsmouth. The company builds the buses — the underlying structure onto which the payload and propulsion systems are built — for most of the European Space Agency’s spacecraft, as well as commercial satellites. The world leader in compact satellite systems, Surrey Satellites (spun out of Surrey University), is also part of Astrium. In support are many smaller companies, producing components such as optics, computing hardware and propulsion.

Materials

The use of new high-performance materials is key to solving many of industry’s biggest challenges. And the UK boasts a wealth of experience in areas ranging from the development of components designed to operate at the heart of a jet engine (see below) to the potential applications of 3D printing to produce functional structural components.

But arguably the most-prominent area of material innovation in UK aerospace is in the design and production of lightweight composite structures and components.

Composite materials are widely seen as being one of the keys to helping the aerospace industry meet its efficiency targets and, with aircraft across the board using the materials in ever-increasing amounts, the UK is very well placed.

On the manufacturing side there are a number of key projects. Airbus is assembling composite wings for its A350XWB at its Broughton facility in Wales. While GKN Aerospace — which has led the way in the development of manufacturing processes for the production of composite components — is manufacturing the rear spar sections for the A350 wing at its Bristol site.

Other key facilities include Bombardier’s Belfast plant, which designed and produced the composite wings for its newly launched C-Series passenger jet, and Spirit Aerosystems composite development centre in Prestwick, Scotland.

This commercial activity is all backed up by a host of composite material producers and suppliers, including Atlas Composites and Umeco, and plenty of healthy activity on the research side: with facilities such as Bristol’s National Composite’s centre helping to investigate new applications for composite materials, and enabling firms to test and refine new industry-scale manufacturing processes.

Engines

It was Britain — courtesy of Frank Whittle — that propelled aviation into the jet age. And although it was initially slow to exploit the potential of Whittle’s invention (the air ministry rejected his idea in the 1920s), the UK is today one of the world’s biggest manufacturers of jet engines.

The main player here is, of course, Rolls-Royce, the world’s second-largest aero-engine manufacturer. Its engines power more than 30 types of commercial aircraft, and it has more 30,000 engines currently in service across both the civil and defence sectors. Sales across both sectors accounted for £1.1bn profit in 2012.

The firm’s flagship Trent product line makes up around 75 per cent of its order book, with variants of the Trent engine used on both the Airbus A380 and the Boeing Dreamliner.

The newest member of the family, the Trent XWB, which boasts a range of innovative features designed to reduce weight and improve efficiency, is poised to enter service on the Airbus A350 XWB in 2014.

In a highly competitive sector, driven by demanding environmental targets, innovation is key, and last year the firm invested £919m in research and development.

A major focus of research is developing blade materials able to operate at exceptionally high temperatures, thereby improving engine efficiency. Last year, the company began work on an advanced aero-engine blade-casting facility in Rotherham that will be capable of manufacturing 100,000 blades per year when fully operational. Each blade will be cast to form a single crystal of super alloy, making it extremely strong and able to resist the intense heat. It will also use new manufacturing techniques such as 3D structured light for geometry inspection.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...