Instead of pushing the tool down from above as a conventional press does, Schuler’s Twin Servo Technology (TST) uses two large servomotors below the bed of the press to pull the tool down. This gives a number of significant advantages in terms of the power requirement, force distribution and rigidity that reduce costs, give better quality parts and enhance die life.

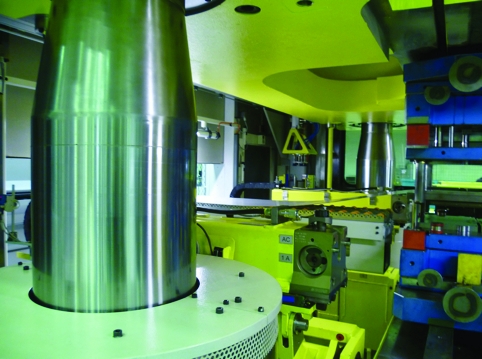

Compared to a conventional press, the construction of the TST press is much simpler. A traditional press has a crown at the top housing the motor and gearing, a side frame to support the crown and linkages to connect the drive from the motors to the press slide that holds the top tool. In the TST press the drives are connected through a low ratio gear to tie rods that pull down the slide.

There is no crown and no side frame. This means that when the press force is applied there is 30% less elastic deformation of the structure of the press – potential energy that is released when the tool breaks through the strip. This drastic reduction in cutting impact gives better quality parts and is gentler on the die. The press is also much more rigid – again giving better quality and die life.

The geometry of a bottom-driven press is particularly suitable for transfer and progression presswork, where the component is formed from a blank or coil in a series of operations along the bed of the press.

Frank Viola, Schuler’s Sales Manager for Automotive Press Technology, explained: ‘You normally have five stages across the press, with the biggest load at the first stage and a very low load at the fifth stage. So you are always going to have an off-centre load on a transfer press.’

This means that there is always going to be a tendency for the slide to tilt during the forming process, and it also means that you need a high tonnage press to achieve the typical off-centre loads required by a transfer press die.

On a traditional press the load is applied at the four corners of the die, but on the TST press it is applied to the corners of the slide – much further away from the centre of the die – so the force available at the first stage of the forming process is around 20% higher for the same press tonnage. This means that on a 1000t press the available force at the first stage could be 600t instead of 500t – or if you only need 500t, you might be able to achieve this with an 800t press.

The bottom-driven TST design, optimised using finite element analysis, is also twice as rigid as a conventional press in the work flow direction, and four times more rigid across the work flow direction.

Together with the reduced vertical deflection, this gives much better part quality and is much gentler on the dies.

The idea of a bottom-driven press is not new; Schuler was making them 100 years ago, but the mechanical gearing required made them extremely complicated machines – hard to maintain and expensive. They finally died out in the 1960s when press makers moved from double-acting presses to single-acting presses with die cushions, as the mechanical drive mechanism meant there was no space in the bed to incorporate this technology.

The advent of powerful servo motors that could be used as the main drive for presses applying thousands of tonnes of force allowed Schuler to revisit the idea. Driving the press with twin, independent servo motors – electronically rather than mechanically linked – overcame all the drawbacks of the mechanical bottom-driven presses and added some new advantages.

In contrast to a conventional eccentric geared press that can only move the press slide up and down according to a sinusoidal curve, the servo motor gives complete control over the speed and position of the slide throughout the press stroke.

This means that the press can be controlled to give a fast approach speed, slow down to the optimum speed for the forming process, and then accelerate up again for the next stroke. There is no need to use the complete stroke of the press either; in what Schuler calls ‘pendular’ mode, the press only moves up and down enough to allow the die to open and close. The result, says Schuler, is that these ‘Servo Direct’ presses can be more than twice as productive as a conventional press.

A further benefit that servo technology brings to the TST press is what Schuler calls ‘active slide parallelism’ compensation.

As Frank Viola explained: ‘On a conventional press, because of the off-centre loads, the slide is slightly tilted when it reaches bottom dead centre because of the force distribution along the bed.’

The geometry of the TST press alone reduces this tilting effect by half compared to a conventional press. In trials at Schuler’s Forming Technology Centre in Erfurt, a die set with a 3mm tilt in a conventional press had an uncompensated tilt of 1.5mm on the TST press.

‘Using the slide adjustment we tilted the slide by 1.5mm to compensate for this,’ said Viola, ‘we then compensated for that by controlling each servo drive independently, changing the velocity so that the slide remained parallel throughout the stroke. So at bottom dead centre we applied the full press force with zero tilting. This really is revolutionary – when we are applying the maximum force, the tilting is completely eliminated.’

Overall, he says, it is still early days when it comes to assessing all the possible advantages of the TST technology, but some are already clear. As well as the improved part quality and die life, the presses are quieter than conventional models, take up less space and, because of the reduced elastic deformation of the press, he expects them to use less energy and require less long-term maintenance.

A final advantage is that the customer can invest in a smaller press: ‘If they can use an 800t press rather than a 1000t press to get the forces they need then you are talking about a lower investment cost,’ said Viola.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...