The future is low carbon. The message has been drummed into us insistently over the past decade and more. Whether the argument is climate change or dwindling resources, we’ve all been told that we need to prepare for a future without oil. However, the reality is that even taking into account reductions in fossil-fuel use, we still get through a hell of a lot of the stuff and we’re going to keep using it for most of the next century, at least.

That means oil has to be moved around in large volumes. With much of the supply in the Middle East and demand distributed around the world, the most practical way of moving the heaviest of hydrocarbons, crude oil, is much the same as it has been for years: big ships.

The workhorses of the oil tanker world are Very Large Crude Carriers (VLCCs) and they’re the biggest things afloat. Typically around 300m long and 60m wide, they ply the main routes – from the Gulf around the Cape of Good Hope and into the ports of Texas; through the Suez Canal and across the Mediterranean to Milford Haven and Western Europe; and around India to Singapore and then on to China – carrying around 300,000 tonnes of crude oil on each voyage. Shipping is one of the most efficient users of energy for transport and, besides, there’s very little choice but to use these oceanic giants for this type of work. However, VLCCs are coming under increasing scrutiny for their own environmental profiles.

Alongside their carbon emissions, there is a particular concern about the amount of other pollutants they produce, notably the oxides of sulphur and nitrogen (SOx and NOx) and particulates resulting from the heavy oil they use as fuel. These are all associated with respiratory illnesses. The Baltic and North Sea are esignated as emissions control areas by the International Marine Organisation (IMO), with the Baltic area coming into force in 2006 and the North Sea in the following year; in these regions, ships must use low-sulphur fuel or fit a scrubber system and must also take steps to rein in NOx and particulates.

Last year, the US and Canada also applied for their entire coastal regions to be declared emissions control areas, out to 200 nautical miles from the coast. This is likely to come into effect in 2012, with emissions limits tightening in the first few years of operation. By 2015, vessels will have to have SOx and particulate emissions more than 85 per cent below current levels, and NOx emissions will have to come down by 80 per cent. The Mediterranean and Black Sea could also become emissions control zones by 2015. Moreover, with the COP16 climate talks in Cancun earlier this month also discussing marine pollution, with a proposal to charge ships docking fees related to their carbon emissions, ship owners and carrier operators are facing up to a need to design a new generation of cleaner VLCCs.

One such design has come from the research department of Norwegian ship classification society Set Norske Veritas (DNV). The Triality concept ship, devised by a 30-strong team of naval architects, financial analysts and specialists in environmental technologies and logistics, was designed with a focus on reducing pollution to air and water rather than on energy efficiency, but despite that, according to chief executive Henrik Madsen, it produces 34 per cent less CO2 than conventional VLCCs. Triality’s environmental performance is markedly better than a conventional tanker; Madsen said that local emissions are ’virtually eliminated’. Moreover, it solves two other problems of VLCCs: the escape of volatile organic compounds (VOCs) from the cargo; and the need for ballast water to ensure that the ship rides at the correct level in the water when emptied of cargo. Taking on ballast water in the port where the oil is unloaded, then travelling to an oil terminal in another continent and discharging the ballast there, leads to the introduction of marine organisms into alien environments that can seriously endanger native species, Madsen said, and international regulators are becoming increasingly concerned about this.

this reduces SOx and particulates by 95 per cent, while it also reduces NOx and CO2 emissions

Torill Grimstag Osberg, project leader

The air-quality improvements in Triality stem from a single change in the way the ship operates: it is fuelled with liquefied natural gas (LNG)rather than heavy fuel oil or marine diesel. ’Directly, without the need for any kind of treatment plant, this reduces SOx and particulates by 95 per cent, while it also reduces NOx and CO2 emissions,’ said project leader Torill Grimstag Osberg. ’Conventional VLCCs need to install scrubber systems for SOx and catalytic converters for NOx; these add complexity and cost, and also have a fuel penalty because they consume energy in operation.’

LNG is a new marine fuel, but it is beginning to make its first footholds in the market and DNV believes that it will become increasingly important in the coming decades. ’There are already about 20 ships around the world that are fuelled by LNG,’ said Osberg, who has previously specialised in safety systems for gas-fuelled ships. ’They’re mostly smaller vessels such as ferries, but one of the goals of this project was to see whether we could design a large vessel to be gas fuelled,’ she added. ’And as VLCCs are the biggest thing on the water, if you can do it with them, you can do it with anything.’

When you’re running a ship on LNG, the biggest problem you have is where to put the fuel tanks, because it takes up quite a lot more space than other fuels

Torill Grimstag Osberg

According to Madsen, there is increasing interest in LNG. ’We haven’t seen many ship owners ordering ships fuelled exclusively by LNG,’ he admitted. ’But we are seeing many owners considering ships that can be run on LNG, heavy oil or marine diesel. At some point it could well become the dominant fuel for merchant ships.’

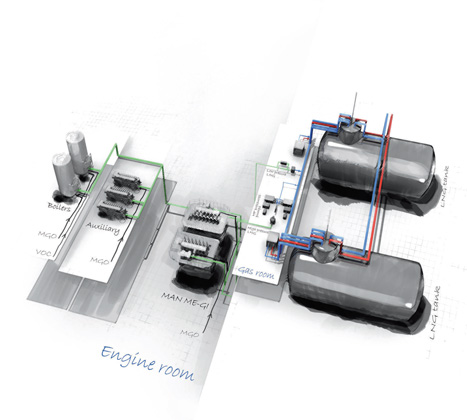

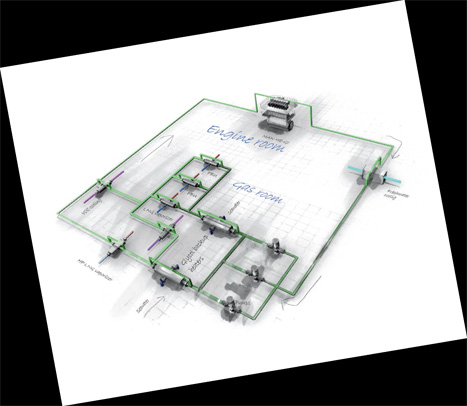

’When you’re running a ship on LNG, the biggest problem you have is where to put the fuel tanks, because it takes up quite a lot more space than other fuels,’ Osberg said. ’But with VLCCs, that actually isn’t much of a problem: there’s lots of space on the cargo deck.’

The Triality concept includes two LNG pressure vessels, each capable of storing 6,750m3 of LNG at -160°C and five-bar pressure; enough for 25,000 nautical miles of operation. This capacity was important, Osberg explained, because ports that carry enough LNG to refuel a VLCC are rare. ’This is enough to go all the way around the world, so a ship that bunkers LNG in the Middle East will have enough fuel to go to the US and back without rebunkering.’ The tanks also have to be able to cope with the increase in pressure caused by evaporation of the LNG during storage, she added.

Standard marine engines can cope with LNG fuelling, so the Triality is equipped with two large dual-fuel two-stroke main engines, which burn natural gas at 300 bar. These engines need to be started using low-sulphur marine gas oil, which is also used as a back-up fuel, particularly when the engines need to operate below 25 per cent loads while manoeuvring at low speed.

One advantage of switching to gas is it removes the need for the equipment to treat heavy fuel oil, a substance that has to be preheated and treated to flow into engines. This reduces the engineering complexity of the ship and therefore cuts costs, Osberg said.

The low temperature of the LNG provides another opportunity. It has to be evaporated and heated to 45°C before it enters the engine, but this means there is potential for cooling on board, something that can come in rather handy. It means that the evaporation of volatile organic compounds (VOCs) from the tanker’s cargo can be recovered.

A VLCC can lose up to 500 tonnes of cargo through evaporation on a typical voyage, Madsen explained. ’The cargo tanks are not designed to handle pressure and as the vapour accumulates, it has to be vented; generally, just to the atmosphere,’ he said. ’There are air-quality implications from this, such as VOCs plus NOx and sunlight-produced ozone, which is toxic. There are also commercial implications, of course, especially as the compounds that escape tend to be the more valuable light fractions from the crude oil.’

The Triality concept includes a system to collect VOCs from the cargo tanks and condense them in a heat exchanger. ’They can be burned as fuel on the voyage, especially during cargo operations, when they can fuel the boilers to produce steam to operate the pumps,’ Osberg said. ’Alternatively, they could be stored for sale at the port. I suspect that would be a commercial decision, based on the prices of the substances in the VOCs and of LNG, but either would be an option.’

The cold LNG is also used to cool the air needed for combustion, in the engines. ’This increases the air you can get into the engine, which enhances efficiency by two to three per cent,’ Osberg said.

The elimination of the need for ballast was achieved by changing the shape of the hull. ’Conventional tankers were mostly designed when the cost of fuel wasn’t a problem and the main concern was getting the maximum amount of cargo on board, so they’re flatbottomed,’ Osberg explained. ’We’ve changed that to a more

V-shaped hull that sits lower in the water at all times, so the propellors are always under water and the bow is down – that’s what ballast does in a conventional ship.’

The concern over marine organisms in ballast is leading ship owners to look at installing water-treatment systems on board to clean the water before it is discharged, but this, like the gastreatment systems, increases complexity and adds cost. Doing away with ballast altogether is a far simpler option, Osberg commented. ’Ships can carry up to 100,000 tonnes of seawater – that’s a huge volume to have to handle and treat,’ she said.

In ’light mode’, the draught at Triality’s bow – the amount of the ship that is under water – is two metres less than the stern, but that is still enough for safe operation, she said. ’Because of the shape, the ship is bigger – 361m long and 70m wide – but the cargo volume is the same. The cost of manufacturing the hull should not be much different from a conventional shape.’

The other reason for using ballast on a tanker is to keep it balanced while loading; conventionally, ballast water is pumped out while the oil is pumped in, which prevents the changing load from twisting the ship. In Triality, this is achieved by a new configuration of cargo tanks. The ship is divided into five sections along its length, with each divided by bulkheads across the ship. Each longitudinal section is filled along its entire length, from the central section outwards, with the pairs of sections on either side of the centre filling simultaneously.

We hope we have shown it is possible to meet environmental targets and still save money, with the efficiency improvements and reduction in fuel requirement that Triality gives us

Henrik Madsen, Chief Executive DNV

Running without ballast also reduces the fuel usage considerably. ’When there’s no water, the wetted surface of the hull is reduced by about 16 per cent, because the ship is so much lighter,’ Osberg said. ’That equates to a fuel reduction of about 11 per cent per year.’

Triality is a concept, Madsen stressed. ’We are not in a position to design ships ourselves and we’re certainly not commissioning them; we have no ambition to be a ship owner ourselves,’ he said. ’We are hoping we can highlight these issues and these innovative solutions, and lead a trend in VLCC design; we hope we have shown it is possible to meet environmental targets and still save money, with the efficiency improvements and reduction in fuel requirement that Triality gives us.

Maybe, in 20 years’ time, my successor will be standing here telling you about a new concept for nuclear-powered merchant ships.’

Floating ideas

A research effort in Britain is also focused on ways of enhancing shipping performance

The UK’s low-carbon shipping project, co-ordinated by the Research Councils and operating across five universities, is looking at many of the same issues that DNV has tackled in Triality. With UCL, Newcastle, Hull, Strathclyde and Plymouth universities joining forces with some 15 industry and government partners, the project is looking at a variety of methods to improve the environmental performance of a whole range of shipping types, but with the priority on energy efficiency and emissions reduction.

The project, which began in May 2010, is divided into six units. UCL is leading an effort to model the global shipping system, using historical data and computing power to represent the major components of the system and the interactions between them. Newcastle and Hull are producing a map of the maritime transport network, looking particularly at the way the UK is connected to it and at possible future options, including new routes such as the Northwest Passage.

Newcastle and Plymouth are looking at the economics of ship production and operation, and how these interact with the economics of the shipping market, including the effects of the industrial cycle on the markets and how possible carbon markets could effect these. Strathclyde and UCL are tackling the technology side of the problem, studying new hull forms, propulsion design, new power-plant options and integration into whole ship designs.

UCL is looking into the possibilities for legislation and regulation on the environmental performance of shipping, which is currently mostly voluntary. This part of the project focuses particularly on carbon emissions and their control. Finally, Strathclyde is carrying out research into the human factor in ship operation and how this can be integrated into low-carbon operation.

Swiss geoengineering start-up targets methane removal

Several rather dubious statistics in this report. IF methane had 120× the thermal effect of CO2 that would be TWO orders of magnitude. Two is not...