The trade buying season for Christmas books is at its hottest in July. That’s when publishers need to have samples ready to convince trade-buyers that their products will fill stockings. Romain Pages (www.romain-pages.com) had a mouth-watering new book of chocolate recipes, written by the firm’s talented chocolatier and finance director Anne Deblois. They had wanted to sell the book pre-packaged with a mould to produce chocolate bars but by the end of May had still not found anyone who could make the mould in the time or quantity needed.

As CEO and editor Jean-Pierre Duval explains: “Romain Pages had not worked with plastic before, so we really needed a reliable sub-contractor.” He got the break he needed in early June, when he came across two websites: one for Protomold, the rapid injection moulding service of Proto Labs and the other, Forum International de Plasturgie (FIP), a trade show in Lyon that month. Within 24 hours of emailing Protomold, Jean-Pierre received a call from Bernard Faure, Protomold’s Technical Sales Manager in France, who outlined the possibilities of rapid injection moulding and arranged a meeting at the FIP show just 10 days later.

Romain Pages is a specialist publisher of books on travel, cookery and the arts. Jean-Pierre founded the firm in 1987 when he was just 24, having trained as a photographer, with the aim of producing beautiful travel guides. Over the years the firm has won numerous national and international awards.

Some five years ago the firm revolutionised the French market by publishing a book of bread recipes that came complete with a bread making machine. The result was a best seller that has sold over 600,000 copies so far. As Jean-Pierre says: “This taught us a valuable lesson; that flexibility is the key to success. Not only did we update the book regularly with completely new recipes but we also included a utensil that was practical and related to the subject matter.”

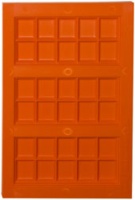

Since then other publishers have copied the idea, but Jean-Pierre and Anne have been determined to stay ahead of the market by developing new concepts. In February 2009 they saw the opportunity for their latest book when they realised that, despite the French eating an average of 7kg of chocolate per person a year, there were no books on how to make your own chocolate bars and no easy-to-use moulds.

Drawing on her own culinary skills, Anne spent the next two months developing and writing 50 recipes, which range from classics like hazelnut chocolate to original ideas such as chocolate flavoured with smoked Sencha tea (inspired by a trip to Japan). Meanwhile, Jean-Pierre shot the sumptuous photographs that illustrate the text.

So when they met Bernard Faure in Lyon on 17 June, they had the book, “Je fais mes tablettes de chocolat” (www.chocolanne.com) and a clear idea of what they wanted for the mould, including Jean-Pierre’s own 2D designs. To their amazement, a few days later they were discussing tweaks and reviewing pricing using their unique online ProtoQutoe®. As Anne says, it was “bien foutu” (“really good”).

However, what really amazed Jean-Pierre and Anne was the speed with which Protomold delivered the first 50 samples. At the FIP show, competitors from France and China had only been able to promise delivery of samples in six weeks (no finished goods for three months; parts from Protomold arrived in a mere two weeks after placing the first order). As a result, Romain Pages had the samples ready for the trade buyers and were able to secure orders from major retailers in France including Fnac, Cultura, Virgin and Amazon.fr.

Jean-Pierre explains: “It was good to be able to choose a European supplier with a French contact – it made the whole process easier to manage.” Most publishers will use Chinese suppliers to package similar books with plastic components but it does not always work out cheaper. One big competitor came unstuck last year when their very beautiful book sold out in a week. Rather than miss the Christmas sales and damage their reputation, the company flew in new stock at a loss. Romain Pages could ill afford to end up in that situation nor could they order large volumes in advance, so were particularly attracted to the fast and flexible low-volume production runs made possible by the Protomold process.

This was wise because, as Jean-Pierre admits: “We made a mistake – a good mistake but a mistake nevertheless.” Romain Pages had produced two versions of the book: one without the mould priced €13.50 and one with priced €24.50. Romain Pages had expected to sell more of the lower-priced books, so had only ordered 10,000 moulds but in the event the market surprised him. “In the first month we sold just 4,000 without the mould but 8000 with.” It was obvious the firm would need more moulds – and fast.

Again Protomold’s rapid injection moulding service gave Romain Pages the flexibility needed to respond quickly to the market’s demands. The first batch of moulds had arrived so soon after Anne placed the order, so she was confident they could deal with the unexpected success and promptly ordered another 5,000 moulds. Three weeks later the second batch arrived and Romain Pages was able to repackage those books without a mould as books with a mould. As Anne says: “It was reassuring to know that we can place an order and if necessary, get them in just a few days.”

With the chocolate book proving a success even before the Christmas rush, Anne and Jean-Pierre are already working on the second and third volumes for 2010, which will include all new recipes and new moulds for different shaped bars and sweets. They are also looking at a new project that just like some of the chocolate recipes, was inspired by their trip to Japan. This project involves ‘Bento’ boxes – and once again Romain Pages will be using Proto Lab’s rapid injection moulding service, Protomold, to add value with well-made and practical utensils.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...