The highly efficient, compact and low maintenance motor is being developed for use in marine propulsion as part of a £1.7m project, co-funded by Innovate UK.

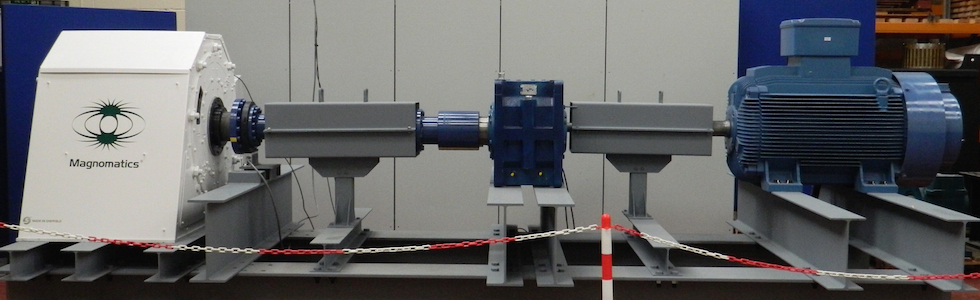

The project team - magnetic gear developer Magnomatics, Rolls-Royce and motor specialist ATB Laurence Scott - will design, manufacture and test a 2.5MW Magnetically Geared Propulsion Motor (MGPN), in a bid to prove its capabilities as a marine propulsion system.

The motor will be powered by a magnetic gear, developed by Magnomatics, a spin-out from Sheffield University. The gear, known as the Pseudo Direct Drive (PDD), uses magnetic fields generated by powerful permanent magnets to transmit mechanical power.

The PDD consists of three rings, each separated by an air gap. The outer and inner rings contain permanent magnets, which are arranged in a north-south pattern. A middle ring, consisting of steel segments, alters the magnetic field between the inner and outer rings.

The force of this magnetic field is transferred across the air gap, causing the rings to rotate, without the need for physical contact between each component.

This lack of contact means there is no friction, increasing the efficiency of the device. It also means there are no wearing parts, eliminating the need for lubricants, and meaning little or no maintenance is needed.

A stator is fitted around the three rings. As current flows through the electrical windings in the stator, it causes the inner magnetic ring to rotate, which in turn prompts the outer ring to rotate.

The device is able to drive a large load, without the need for a mechanical gear box.

The efficiency benefits and low maintenance of the new motor should allow more flexible propulsion systems to be used on different types of vessel, according to Andrew Myers, general manager of the drive technology division at Magnomatics.

“The use of a magnetically geared PDD compared to conventional permanent magnet propulsion systems will result in a compact, low-maintenance, robust and flexible propulsion system that could improve efficiencies and cut emissions for many types of vessel,” he said.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...