Denmark is no stranger to challenging infrastructure projects. Over the years – primarily in an effort to improve the transport links between the country’s mainland and its largest islands – it has built a host of record-breaking bridges and tunnels that have cemented its reputation as a global centre of structural engineering excellence.

But now, its civil engineers are poised to begin a construction project that could be the country’s most challenging yet: an 18km-long sub-sea tunnel that will link the German island of Fehmarn with the Danish island of Lolland. Its proponents claim that it will fundamentally transform transport in the region, replacing around two million ferry journeys annually, and slashing rail travel time between Copenhagen and Hamburg by more than 25 per cent.

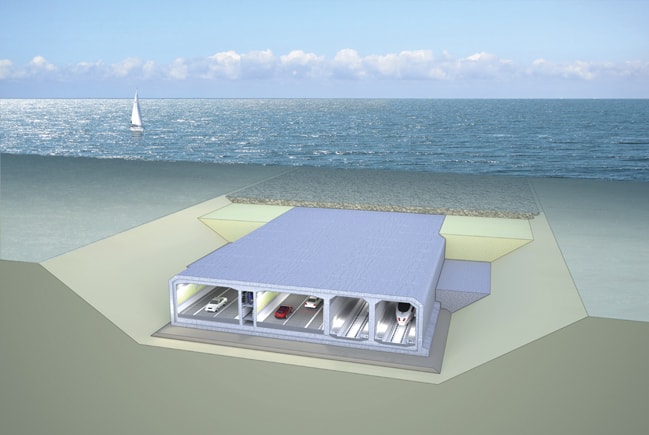

Dubbed the Fehmarn Belt Fixed Link (after the Baltic strait separating the two islands), the new link will be the longest immersed tunnel ever built and will be five times longer than the current record-holder, the Øresund tunnel, which is also in Denmark. Constructed from vast pre-fabricated concrete sections that will be installed in a trench on the seabed up to 35m beneath the surface, the tunnel will comprise twin railway lines, four motorway lanes and a separate emergency tube.

Kim Smedegaard Andersen is the technical director for Femern A/S, the Danish government-owned organisation responsible for building the tunnel.

He explained to The Engineer that a direct link across the Fehmarn Belt has been under discussion for a number of years, but that a tunnel was chosen as the preferred solution primarily because of the distance of the link, the water depth in the Fehmarn belt and a host of environmental factors. “A tunnel below the seabed will cause some environmental disruption during construction,” he said,

“but once in place it will be neutral, while a bridge, which would have giant pillars would constantly impact on the environment.”

The decision to build an immersed tunnel rather than a bored tunnel such as those recently excavated for London’s Crossrail project was, he added, driven by both the desired size of the tunnel (it would require the largest tunnel-boring machine ever built) and the complex geology of the region. “We don’t have a uniform soil type, there are some very plastic clays and some very hard marine clays with a lot of flint and it can be a very complicated to construct machinery which can cope with material changing from sand and silt to clay and so forth.”

The project has been formally approved in Denmark, and the team is now waiting for it to be signed off by the German government. Once this happens, a mammoth manufacturing and engineering operation will begin.

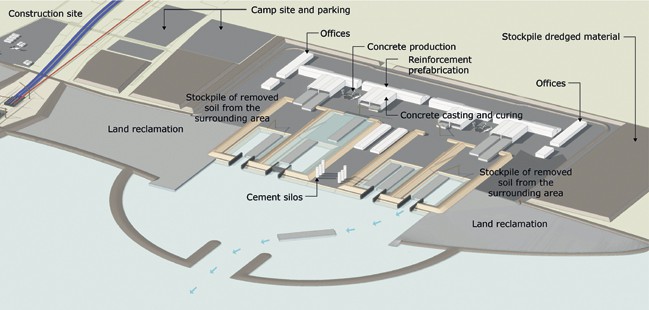

The first step will be the construction of a giant purpose-built manufacturing facility and harbour near Rødbyhavn, on the south coast of the Danish island of Lolland.

Here, eight identical production lines will be set up for the continuous casting of the huge reinforced concrete elements that will form the structure of tunnel.

Made from a series of nine identical segments that are joined together during the manufacturing process, each element will weigh approximately 73,000 tonnes and will be 217m long, 9m high and 42m wide. A total of 89 separate elements will be produced for the tunnel. Ten of these will feature a special additional deck beneath the traffic tube that will be used to carry out maintenance work once the tunnel is operational. This, said Andersen is a completely new innovation in immersed tunnel design that has been necessitated by the distance of the crossing. “Most tunnels are so short you are only operating from the poles,” he added.

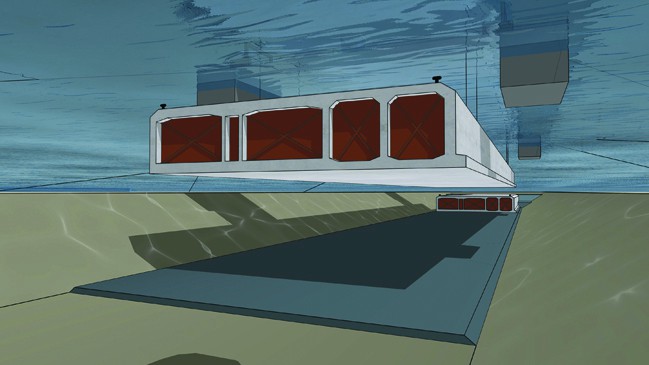

Once an element has been cast, watertight steel bulkheads will be added to each end of element to ensure that it floats and it will be pushed into a basin and towed to a holding area near the trench.

The element will then be connected to advanced pontoons that will be used to carefully guide it to the immersion site.

Once positioned directly above the trench, cables anchored to the seabed will hold the element in position, and its ballast tanks will be filled with water to enable it to sink to the seabed. Its descent to the immersion site will be carefully controlled by cables attached to the immersion pontoon while a combination of GPS and sonar will help guide the giant structure to its final resting place.

The next challenge is connecting the separate elements together on the seabed in order to form the tunnel, and this is achieved using an elegant process that Andersen likens to “a great big kiss”. When the tunnel element has been placed in the tunnel trench and lined up with the previous one, a hydraulic arm will be used to haul the new element right up to the existing one.

As the elements are brought together, huge rubber gaskets mounted on their ends will form a watertight chamber between the steel bulkheads. Water is then pumped out of this chamber, until it’s at normal atmospheric pressure, and the considerably higher water pressure on the free end will force the elements close together creating a watertight seal.

This will continue until all the elements are in place. They’ll then be secured in the tunnel trench with gravel and sand, and covered with a protective layer of stone. The top layer of stone will be level with the existing seabed and the tunnel itself will be safely below the seabed, protected against ship anchors and other collisions.

Once that process is complete, the engineering team can then set about installing the road and rail infrastructure that will, says Andersen, make the Fehmarn tunnel one of the most advanced links of its kind in the world.

Much of the technology that will be deployed in the tunnel is, he said, still to be decided. Safety and traffic management systems are evolving rapidly and with the project expected to take around eight years to complete, he and his team are watching developments around the world with interest.

In the meantime, with the Danish parliament giving the scheme the go-ahead earlier this summer, Andersen and his team are anxiously awaiting a similar vote of confidence from the German federal government.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...