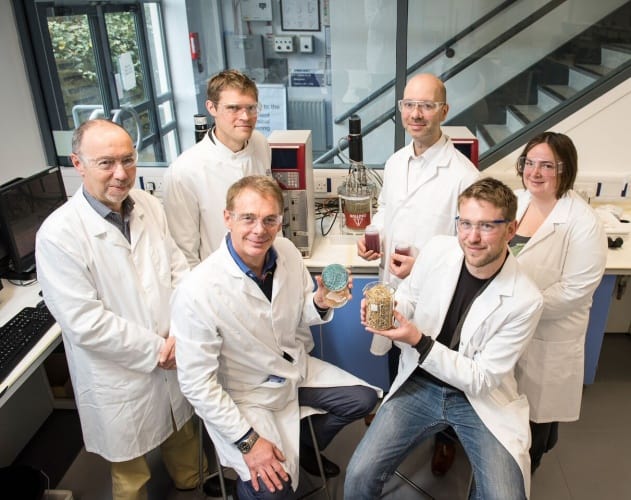

Researchers from the Universities of Bath and York are working on a yeast-based alternative to palm oil, which they hope to be able to produce on an industrial scale.

Palm oil has a wide range of uses including biofuel, cosmetics and as an ingredient in foods such as cakes and biscuits. However, farming of palm is associated with widespread deforestation, particularly in parts of South East Asia. The environmental impact includes loss of habitat for wildlife, water pollution, and carbon emissions resulting from fires used to clear the land.

Previous work at Bath involved the production of a thick oil nearly identical in properties to palm oil, using the yeast Metschnikowia pulcherrima. The yeast can be grown under non-sterile conditions on a variety of agricultural and food wastes, and the researchers believe it could provide an alternative to palm and the destructive farming methods that often accompany it.

“This project is an exciting opportunity for us to develop a renewable alternative to palm oil, while developing further sustainable technologies that could have a significant impact on many other UK sectors,” said lead researcher Dr Chris Chuck, from Bath’s Department of Chemical Engineering.

“The yeast is naturally oleaginous, which means that certain strains can accumulate triglyceride oils within the cell. If you culture the yeast under the right conditions we can get up to 50 per cent of the cell weight to be oil. Certain conditions, different strains and growing methods will change the composition of the oil, but it is possible to match the composition exactly to palm oil.”

The team has just been awarded a £4.4m grant via BBSRC, EPSRC and Innovate UK to further develop the technology and techniques. To commercialise the process, production must be scaled-up to industrial levels. According to Chuck, this will involve some engineering challenges, but also opportunities to harvest by-products to help mitigate the costs.

[embed]http://bcove.me/zjo487o0[/embed]

“Oleaginous yeasts are grown aerobically so it is important to provide enough oxygen, (but) on a larger scale this is tricky to do cost effectively,” he told The Engineer.

“We are also aiming to continually extract co-products to reduce the overall costs of the oil. Development of an effective system to continually strip these is also part of the grant. Finally, for the yeast, extracting the oil by low energy means is another key challenge that we are applying novel technology to.”

Chuck says that one of the biggest challenges is developing cost-effective methods to depolymerise the feedstock. This needs to be done to release mono and oligo saccharides that the yeast can be grown on, but requires microwave heating. Scaling this up is a part of the grant project that the University of York is handling.

“The grant is for developing the separate technologies together and demonstrating on the lab scale,” Chuck explained.

“The aim is to have brought these technologies together and scale up to a pilot scale demonstration by the end of the four years. If all goes to plan we will then be aiming to commercialise through our industrial stakeholders after this point.”

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...