Vlatko Vlakovic

Education

BSc electrical engineering University of Novi Sad, former Yugoslavia

MSc electrical engineering Virginia Tech

PhD power electronics Virginia Tech

Career

1994: Joined GE Global Research, leading projects with GE Medical Systems, Industrial Systems and Transportation Systems.

Subsequently: manager, Power Controls Lab

Global Technology Leader, Electronic & Photonic Systems Technologies

2012: Joins newly created Power Conversion business

2013: Named head of engineering

Vlatko Vlatkovic has little time for those who argue that renewable energy will always be dependent on government subsidy. ‘Just not true’, said the chief technology officer of GE’s power conversion business. ‘The cost of these technologies has been falling for the past 10 years. Although it’s true that subsidies are an important driver at the moment, especially for wind and solar, we’re not too far away from the situation where we’re at parity with energy generated from fossil fuels. We’ll certainly have parity within the next 10 years, no question.’

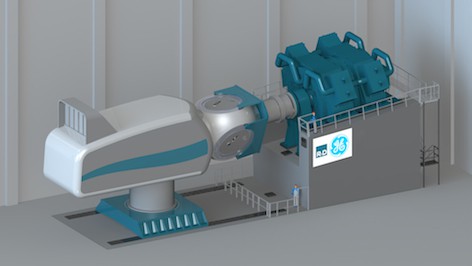

Power conversion is a relatively new division within GE, created in 2012 to stand alongside its established businesses in power generation gas turbines and jet engines, healthcare and oil and gas. Vlatkovic has been in the business since its inception, joining after four years in the oil and gas business, before which he had worked in the company’s central R&D division in upstate New York.

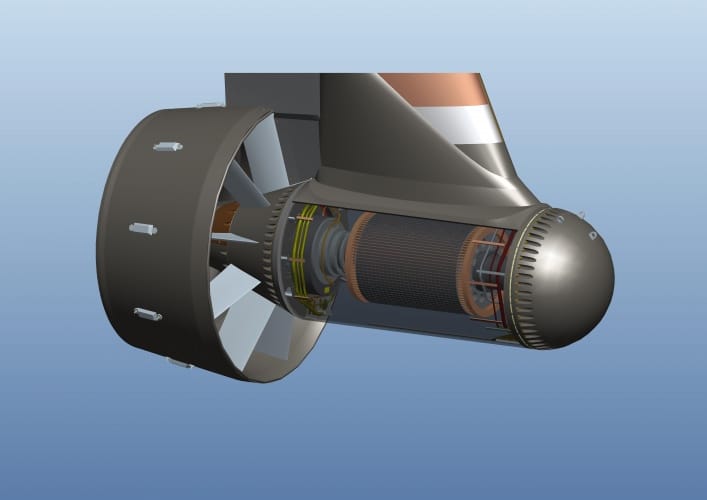

The division makes electrical and electronic equipment that works as an ancillary to power generation, converting the motion of gas and wind turbines into electric current and including the power electronics and switchgear to manage the electricity and get it onto distribution grids. ‘We make rotating machinery, generators, motors, powertronics and batteries, mostly infrastructure scale; we have applications in sectors from power generation, oil and gas, marine, general purpose industry from steel mills and mining,’ Vlatkovic said. ‘Infrastructure scale means anywhere from a few megawatts to hundreds of megawatts.’

Although GE doesn’t directly manufacture generating equipment for renewables, it is closely associated with the sector because it makes all the ancillary equipment needed for renewable energy. In solar, for example, it has formed a partnership with US cadmium telluride photovoltaic specialist First Solar and is involved in the quest to bring down the cost of solar farms. ‘A key part of that is scaling up the equipment,’ Vlatkovic said. ‘One of our core products, along with the rest of the industry, is a converter rated at a megawatt — 1,000VDC — and you’d stack those together to make a solar farm; 20 of them for a 20MW farm, obviously. But we’ve recently introduced a unit which is 4MW, 1,500VDC, and that reduces cost in terms of capital and operational expenditure; you only need to build the foundations for one equipment station instead of four, you only need to maintain one set of equipment, and the higher voltage rating means you can put 50 per cent more power through the cables.’

Demand is strong for solar equipment in First Solar’s home market of the south-western US — California, Nevada and Texas — and also in the oil-rich states of the Middle East. ‘The Middle East is showing increasing interest in renewables to generate electricity for their own grids,’ Vlatkovic said. ‘They’d far rather sell their oil and gas than burn it. The renewables market in Saudi Arabia is becoming very important and I think it’s going to remain so.’ In Europe, demand is slackening from the southern regions of Spain and Italy, where it had previously been strong, because of those countries’ financial woes; it is now growing faster in the UK and Germany.

Scale-up of installations is the most important driver for reducing cost in solar, but Vlatkovic emphasises that development is ongoing across the whole range of equipment and there is plenty of room for improvement. This is true for the whole renewables sector, he stressed. ‘When it comes to gas turbines, for example, we have to expend a lot of effort and development budget to get just one or two per cent more efficiency out of them; the technology’s been around for a long time and there’s been decades of work to optimise it already. That’s not true for renewables. The constituent technologies, the power electronics, the architecture of the wind turbine and the solar farm are still relatively new and there are a lot of things you can do to scale them up and reduce the cost. I can see over the next 10 years the cost of these renewables coming down 30–40 per cent for sure.’

’According to our studies you need about four per cent of the renewable generation capacity as energy storage, so for a 100MW wind farm, you’d only need 4MW of storage

There are two main avenues for technological improvement in renewables, Vlatkovic said. The first is in the basic equipment itself: photovoltaic cells and modules for solar, as well as the way they are packaged; for wind, blade design and generators; and for both, power electronics. The other area for both is the systems side. How does one design the architecture of a wind or solar farm to reduce the cost? There we’re looking at things such as moving more towards DC architecture. A third area is enterprise-scale controls and large-scale grid integration. Those three areas will continue to see investment and you will see progress. There’s a lot of technology in there that’s under development and that’s going to have a continual impact on the cost.’

Equipment from the wind energy development stream is also in use in marine energy projects in Wales and Orkney, Vlatkovic said, although he conceded that development in this sector is considerably behind wind and solar.

Another strand of GE’s business is looking at energy storage. ‘We have a batteries business, which we started from scratch, based around technology developed in upstate New York,’ Vlatkovic said ‘and we have a factory there making cells based on sodium metal halide technology.’ That’s very different from the more familiar lithium-ion technology, he said. ‘That’s good for high-power-density applications but it’s rather expensive for utility scale. Sodium metal halide is better for higher energy density and it’s tailored for utilities where you want to store more energy.’ GE’s products in this sphere include a 1MW unit including inverters and power electronics that fits into a standard shipping container, can be plugged straight into a grid, and can also be used for remote power for applications such as mobile-phone towers.

The question of grid-connected energy storage is, of course, a vital part of the integration of renewables into the grid. Vlatkovic thinks that this is not as big a problem as many might believe. ‘Every power plant has energy storage; they all have a gas tank or a lake or a pile of coal or uranium; and they’re all used to responding to fluctuations in demand,’ he said. ‘The question is not so much do I need to add storage to deal with intermittency, it is how do I integrate with the capability of the existing plants to offset the intermittency.’

Conventional grids are, in fact, already configured to cope with intermittency, Vlatkovic said; demand, or load, fluctuates throughout the day and balancing mechanisms are built into the system to cope with that, bringing large amounts of energy onto the grid to cope with peaks. The intermittency of renewables is ‘just negative load’, he insists. ‘When you have very large penetration of renewables — say 20–30 per cent — then you’d need some storage, but actually not all that much. According to our studies it’s about four per cent of the renewable capacity, so for a 100MW wind farm, you’d only need 4MW of storage. It’s then that you need to think about storage — what type you need, and how to mix and balance battery storage with hydro, flywheel or whatever other type. It’s actually much more of a grid integration issue than a matter of “do I need to add batteries”.’

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...