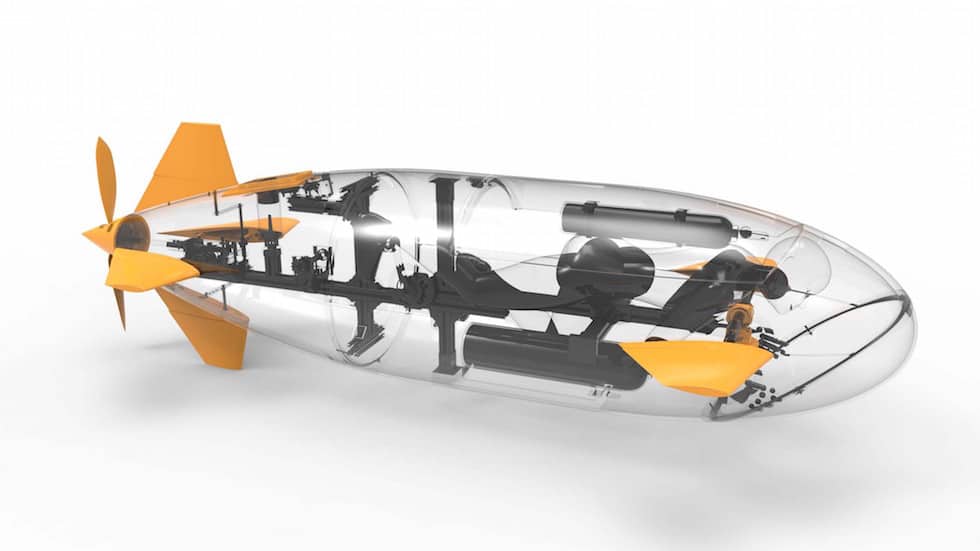

Dubbed Godiva 2, the Warwick team’s vessel is said to feature numerous 3D printed parts designed to withstand the challenging environment in which it will race. These parts include the fins, and the feet in which they sit, the propeller shroud and blades, plus a number of fixings, housings and internal steering components.

According to Josh Dobson, project leader of the Warwick Submarine team, the use of its Fortus 3D Printer from Stratasys has been integral to building the submarine in time for the race, as well as keeping costs within budget.

“Using this technology, we were able to 3D print final parts for the submarine 90 per cent faster than using conventional manufacturing and also saved £2,000-£3,000 in manufacturing costs,” said Josh. “These are parts that can perform in the harshest waters, which is incredible given the speed and cost at which they can be produced.”

Running for its fourth year, the academic project challenges final year Masters engineering students to build and race a human-powered submarine at the annual European International Submarine Races, which take place in Gosport, Hants between July 6-15.

The current project involved designing and manufacturing the submarine, which the students performed under the supervision of WMG’s Dr Ian Tuersley in their pit area within WMG’s Engineering Hall.

The team used of Stratasys 3D printing when building a prototype for last year’s competition, and for 2016 they have extended the use of 3D printing technology to include the manufacture of final production parts capable of performing in racing conditions. To help with this, the students used Stratasys’ advanced ABS-M30 material in their Fortus 3D Printer.

“The material development over the last few years at Stratasys has been integral to the evolution of 3D printing from beyond solely a prototyping tool right through to where we are today; 3D printing parts for direct use on our submarine,” said Josh. “All the parts were produced from ABS-M30, apart from the propeller blades which were 3D printed by Stratasys in the USA.

“Having access to this technology gives us the flexibility to produce extremely complex and multi-functional parts cost-effectively and on-demand,” added Josh. “For example, our fixing feet are an incredibly complex piece of geometry and have been 3D printed to perfectly fit the hull at virtually no additional cost, yet remain as functional and strong as a traditionally manufactured part. In addition, by creating the part using 3D printing, we’ve reduced material wastage by about 75 per cent compared to machining the part traditionally from a solid piece of metal, which bodes well for a future of more sustainable manufacturing.”

Known as ‘WarwickSub’, the team of six students are from various multi-disciplinary backgrounds including mechanical and manufacturing engineering. In addition to building their submarine, the students spent a significant amount of time engaging with other school pupils to encourage the uptake of STEM subjects, as well as working with industry partners internationally to learn more about the latest innovations in engineering.

Project to investigate hybrid approach to titanium manufacturing

What is this a hybrid of? Superplastic forming tends to be performed slowly as otherwise the behaviour is the hot creep that typifies hot...