The findings are reported in Advanced Materials, in a paper by MIT graduate student Grace Gu, postdoc Mahdi Takaffoli, and McAfee Professor of Engineering Markus Buehler.

According to GU, conch shells possess a unique architecture with a structure that makes the material 10 times tougher than nacre, commonly known as mother of pearl. This resistance to fractures comes from a unique configuration based on three different levels of hierarchy in the material’s internal structure.

The three-tiered structure makes it very hard for any tiny cracks to propagate; the material has a “zigzag matrix, so the crack has to go through a kind of a maze” in order to spread, said Gu.

The structure of a conch shell is well understood but replicating it has so far proved challenging. “But now, our lab has developed 3D printing technology that allows us to duplicate that structure and be able to test it,” said Buehler, who is the head of the Department of Civil and Environmental Engineering.

Part of the innovation involved in this project was the team’s ability to simulate the material’s behaviour and analyse its performance under realistic conditions. “In the past, a lot of testing [of protective materials] was static testing,” Gu said. However, a lot of applications for military uses or sports involve highly dynamic loading, which requires a detailed examination of how an impact’s effects spread out over time.

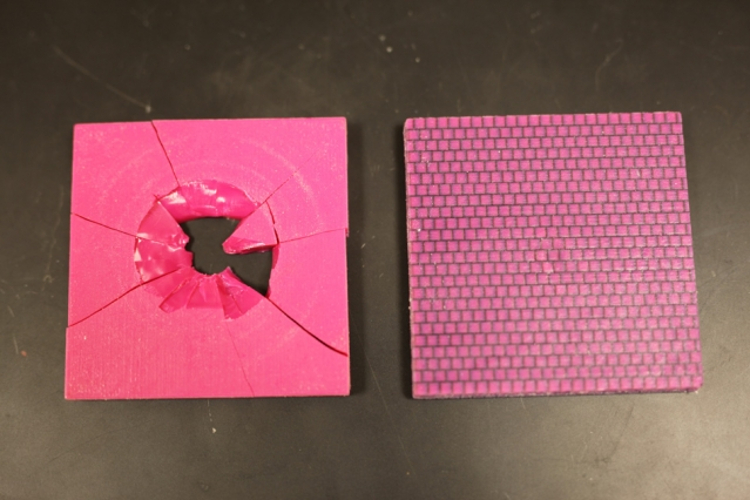

According to MIT, the researchers did tests in a drop tower that enabled them to observe exactly how cracks appeared and spread - or didn’t spread - in the first instants after an impact. “There was amazing agreement between the model and the experiments,” Buehler said.

That’s partly because the team was able to 3D print composite materials with precisely controlled structures, rather than using samples of real shells, which can have unpredictable variations that can complicate the analysis.

By printing the samples, the team were able to use the same geometry as used in the computer simulations and get very good agreement. Now, in continuing the work, they can focus on making slight variations as a basis for future optimisation, Buehler said.

To test the relative importance of the three levels of structure, the team tried making variations of the material with different levels of hierarchy. Higher levels of hierarchy are introduced by incorporating smaller length-scale features into the composite, as in an actual conch shell. Lower-level structures proved to be significantly weaker than the highest level pursued in this study, which consisted of the cross-lamellar features inherent in natural conch shells.

Testing proved that the geometry with the conch-like, criss-crossed features was 85 per cent better at preventing crack propagation than the strongest base material, and 70 per cent better than a traditional fibre composite arrangement, Gu said.

Swiss geoengineering start-up targets methane removal

Several rather dubious statistics in this report. IF methane had 120× the thermal effect of CO2 that would be TWO orders of magnitude. Two is not...