Stuart Nathan

Stuart Nathan

Features editor

Airbus's innovation event was geared around new materials and methods for aircraft manufacture and meeting the increasing demand for flying

It’s entirely a coincidence, but as my colleague Andrew wrote about his week in aerospace last Friday, my week has also been dominated by this sector. However, my experience was somewhat different from Andrew’s; I’ve been a guest at Airbus’s annual Innovation Days event, held at the company’s vast site in a particularly sweltering Hamburg, where it shows off what’s new within the company.

Innovation is of course a word with many meanings. While we at The Engineer would tend to define it as the development of technology – in Airbus’s case, to either improve the aircraft themselves or how they are built – to the company it encompasses a vast array of other ideas. These include changes to business processes, for example, or research into the effects of lighting and cabin décor on passengers’ state of mind. While this can throw up some fascinating nuggets of information (for example, if you make the seats a little bit wider, you can put more rows of seats in the cabin without affecting the passengers’ perception of comfort) it generally wouldn’t be of much interest to our readers.

Touring the manufacturing areas of the site, however, revealed an industry and a company on the cusp of great changes. In response to increasing demand for air travel, with the Asian market growing particularly fast as the growing middle-classes in India and China use their newly-found disposable income to fly rather than travelling vast distances by train, Airbus is ramping up its production rates from what’s known in the sector as ‘rate 30’ (30 aircraft a month) to rate 60.

As chief operating officer Tom Williams told the 160 international journalists attending the huge event, as recently as 2005 this would have been thought impossible. Airbus made 30 single-aisle aircraft in 2005, and ‘people said that producing at a rate of more than one finished aircraft per day would break the laws of physics.’ These days, however, the assembly teams can complete an A380 fuselage section every five hours, and assembly times on wings at the Broughton plant in North Wales are being reduced from ten days for a pair of finished wings to six.

This can’t challenge the rates achieved in the automotive sector, Williams conceded, but that would be impossible for two reasons. First, airliners are just too big and complex to be made on an automotive-style production line (although increasing numbers of sub-assemblies can be); and second, as chief executive Fabrice Brégier pointed out, the aerospace industry only builds an aircraft when it has contracts in place from a customer to do so, whereas the automotive sector will build as many cars as it can and then work out how to sell them.

But in the cavernous hangers where Hamburg’s workers build aircraft sections and assemble them, the influence of automotive techniques can be seen clearly. Those A380 fuselage sections are built on a modular basis, looming in giant slices within jigs purpose-built to accommodate technicians working on several aspects of the build at the same time. Smart tooling in also much in evidence; The Engineer has written before about how Airbus is using industry 4.0 techniques so that tools in use ‘know’ how much force to use to tighten a particular bolt, for example, and Williams also mentioned a smart drill designed to cut through a stack of different materials, controlling the bit speed according to what’s necessary for each material in the stack to achieve a clean bore. The company is also making use of exoskeleton technology, such as a spring-loaded arm (modified from the Steadicam mounts we’re familiar with from TV sports coverage) which can help an operator lift a 12kg, top-heavy tool into a position with its business end his above his or her head some 600 times per shift with little fatigue and no chance of injury.

Another area where change is becoming apparent is in materials. The use of composites is becoming more and more prevalent in aircraft, and the hall at the site dominated by an enormous autoclave for curing the 27m-long wing covers of the A350 series is testament to that. The vertical tailplanes of all aircraft are made down the road from Hamburg in Stade, and these are entirely composite constructions (the towering sharkfin-shape of an A380 tailplane is a sight to behold). Since March of this year, tailplanes are being painted using enormous vertical inkjet printers; a technique originating in bus and truck manufacturing. This is both fast, because designs can be printed in a single operation rather than built up laboriously layer by layer with drying times between each application; and it helps reduce weight. A printed A320 tailplane is 5kg lighter than a painted one because the ink layer is 3µm thick, as opposed to 120µm for an airbrush-applied paint layer.

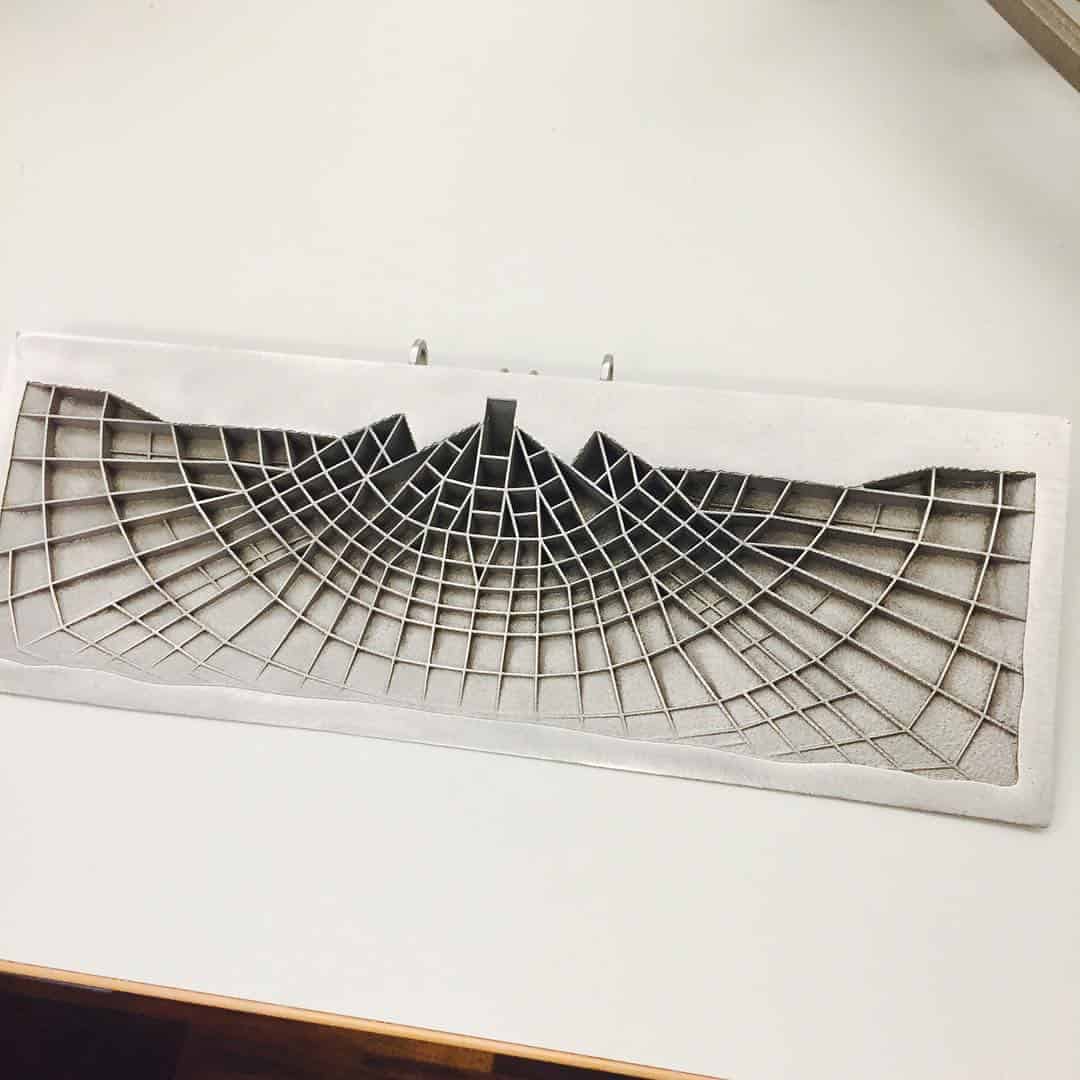

Additive manufacturing is also now beginning to proceed beyond mere potential into reality, at least at the testing level. Numerous additively-produced components were on show, including a model for an airbrake panel with reinforcing ribs modelled after those of a water-lily leaf: this, said head of emerging technologies Peter Sander, is even lighter than a composite component. It is planned to be tested at full-scale on an A320 family aircraft by 2018.

Also on display was THOR, an entirely 3D-printed unmanned aircraft. Made from resin sections, it took about two months to print and assemble. This technology will be used to test both new aerodynamic configurations and subsystems such as electric propulsion and micromechanical sensors to measure parameters such as air pressure on the structure. Effectively expandable, THOR provides a low-risk and relatively fast way of testing structures and systems by trial and error that has not been previously available; it might also be a valuable tool in the training of aerospace engineers or even to attract schoolchildren into further engineering education.

The various engineering presentations at the event left attendees in no doubt about the main thrust of Airbus’s R&D; it’s to produce aircraft that are more efficient in their use of fuel and allow their customers to maximise the revenue they can generate, by finding ways to increase passenger numbers while minimising the effect on passenger comfort. As Fabrice Brégier put it, airport expansion is limited, but more people want to fly; the only way to accommodate these two facts is to get more people onto aircraft, either by making bigger airliners or increasing the capacity of existing fuselages.

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?