According to a statement from MIT, the scientists believe that relatively simple, microscale roughening of a surface can dramatically enhance its transfer of heat. They claim the new approach could be far less complex and more durable than previous heat-transfer enhancement solutions.

Evelyn Wang, co-author of the paper and associate professor of mechanical engineering at MIT, believes heat dissipation is a major problem in many fields, especially electronics.

Wang claimed the use of phase-change liquids, such as boiling water to transfer heat away from a surface, has been an area of significant interest for many decades.

However, there has not been a good understanding of the parameters that determine how different materials — and especially surface texturing — might affect heat-transfer performance.

Wang said recent advances in microtechnology and nanotechnology has enabled scientists to manipulate surfaces to optimise the process.

The team found that the reason surface roughness greatly enhances heat transfer — more than doubling the maximum heat dissipation — is that it enhances capillary action at the surface, helping keep a line of vapour bubbles ‘pinned’ to the heat-transfer surface, delaying the formation of a vapour layer that greatly reduces cooling.

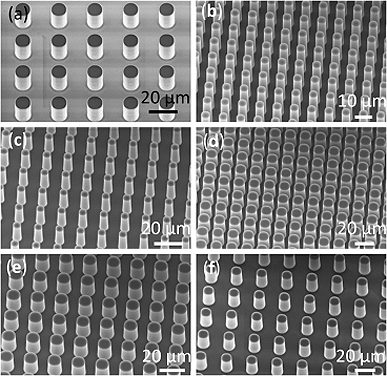

To test the process, the researchers made a series of postage-stamp-sized silicon wafers with varying degrees of surface roughness, including some perfectly smooth samples for comparison.

The degree of roughness is measured as the portion of the surface area that can come into contact with a liquid, as compared to a completely smooth surface

The researchers found that systematically increasing roughness led to a proportional increase in heat-dissipation capability, regardless of the dimensions of the surface-roughening features.

The results showed that a simple roughening of the surface improved heat transfer as much as the best previous techniques studied, which used a much more complex process to produce nanoscale patterns on the surface.

Wang believes the research is an important first step to understanding what kind of structures are needed for successful heat transfer.

While the most immediate applications would likely be in high-performance electronic devices, and perhaps in concentrated solar-power systems, the same principles could apply to larger systems such as power-plant boilers, desalination plants or nuclear reactors.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...