Space, as Captains Kirk and Picard so memorably said, is the final frontier. And not just for exploration. As plans for human presence in the solar system become more developed, researchers are increasingly looking for ways to expand hitherto earthbound areas of human activity into space. As a recent conference at Coventry’s Manufacturing Technology Centre explored, one area is manufacturing.

A very specific area of manufacturing is being studied: building spacecraft and items that human explorers might need on their missions (whether they last five years or even longer), such as shelters, habitats and tools, in space. The first stages of this are already beginning to be investigated: in-orbit assembly of spacecraft had notable success in the late 1980s and early 1990s, with the construction of the International Space Station (ISS) from modules transported by Russian launchers and the Space Shuttle, and assembled either by autonomous docking manoeuvres or astronaut crews.

The rationale behind off-planet manufacture is the same as the ISS build strategy: it’s easier to construct awkwardly shaped and large items in situ than to build them on Earth and launch them into orbit. They don’t have to withstand the vibration and rigours of launch, or be packaged for safe transport. The only thing that matters is the mass of the raw materials that need transporting.

This, of course, is theoretical. Easier it may be, but the task of actually building something still needs to be overcome and, until relatively recently, very few of the established manufacturing techniques were suitable (or practical) for a use in microgravity conditions.

The Engineer’s previous forays into this sector looked at techniques such as extrusion of plastics to make long booms, but ability to build the major modules of spacecraft, for example, were completely lacking.

This has been changed by the emergence of additive manufacturing techniques, which take very simple forms of raw material, such as powder or wire, and turn them into relatively complex, three-dimensional geometrical shapes. These would allow complex structures to be built in space, with the need to transport raw materials in a compact form into orbit.

According to Tony Mears of the UK Space Agency, “[Additive manufacturing] has the potential to shake up space manufacturing like nothing else. From wiping out the cost of traditional machinery, to making new designs, additive manufacturing is changing how we approach optical instruments, mirrors, even rocket engines. The UK Space Agency has funded projects across all these to mid-TRL (technology readiness level) and they all have a promising future ahead in commercial applications.”

Not all additive techniques are suitable for use in space. The technique most commonly referred to as 3D printing, powder-bed additive layer manufacturing – where a laser is used to melt a metal or polymer powder to build up an item slice-by-slice – is not suitable. Prof Richard Hague, director of the centre for additive manufacturing at the University of Nottingham, explained to The Engineer that in the absence of gravity, it would be impossible to consolidate a powder bed inside a 3D printer and, therefore, the technique would be impossible.

One technique that is showing promise, however, is wire + arc additive manufacturing (WAAM). Derived from welding, this uses an electric arc effector mounted on the robot arm to deposit metal from a wire, into whatever shape the effector arm is programmed to describe. As it is simple for such a system to move in circles, it is particularly well suited to making round-ended cylinders and spheres – both of which are shapes commonly used for space vehicles and habitats. Tanks designed to hold pressurised gases are very commonly shaped like this.

Cranfield University has played a key role in developing WAAM and is looking at space applications for the technique. Earlier this year, it collaborated with Thales Alenia Space and Scottish company Glenalmond Technologies, which is focusing on using the technique with high-grade metals, to build a full-scale prototype of a titanium alloy pressure vessel designed for space applications. Weighing 8.5kg and measuring a metre in length, the tank is made from the alloy Ti-6Al-4V, a high strength-to-weight ratio material commonly used for applications in the aerospace and biomedical sectors.

At the MTC conference, design engineer Abdul Haque of the Advanced Manufacturing Research Centre spoke about a project to build a spherical titanium propellant tank for a CubeSat, designed to hold ammonia to be used in a microwave-enabled electrothermal thruster system. This project, with industrial partner AVS Space, was undertaken as part of AMRC/Space, which was set up in September 2018 to explore opportunities in the UK manufacturing base to support the government’s vision for a “great British space age”. The tank met the internal pressure standards needed for such an application, Haque said.

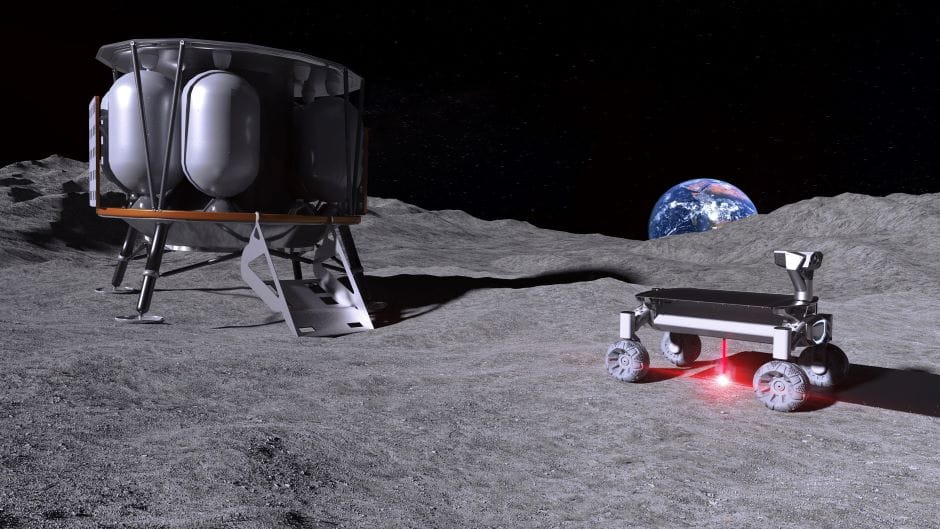

Another application where additive manufacturing for space has attracted great interest is in building habitats for astronauts on the moon, with an eye to later application in crewed missions to Mars. Once again, the rationale is to remove the need to transport bulky and heavy items from Earth to targeted landing sites. The goal in these cases is generally to use in situ resource utilisation (ISRU) for the raw materials to build the modules: in other words, to use lunar (or martian) soil, known as regolith. ISRU is currently the object of much interest for lunar return missions.

With new lunar missions now firmly on the timetable, interest in additive habitats has intensified, and at the end of May this year, Laser Zentrum Hannover (LZH), a German independent research Institute, in association with the Institute of Space Systems of the Technical University of Braunschweig (IRAS), announced a new phase of a project called MOONRISE, which began in 2015. IRAS research leader Prof Enrico Stoll said that the project equipment, a low-weight laser that can melt lunar regolith to redeposit it in a robot-controlled additive extrusion system, will hitch a ride on an ESA-led lunar mission by the end of 2021.

The MOONRISE laser weighs 3kg, and the team is currently adapting it to fit into a tunnel on the base of a lunar rover. Before the mission, the system will be tested to ensure that it can withstand the transit conditions and operate in the environment of the Moon. Testing has now been under way on the equipment for 10 months. LZH research leader Prof Ludger Overmeyer said that the challenge of ensuring the process is safe and equipment within the mass budget is considerable, but that progress is promising.

The project is being funded by the Volkswagen Foundation, Germany’s largest independent funder of basic research, which grants awards for new projects at the rate of €100m (£89m) per year. Despite its name, it is not affiliated to the automotive giant.

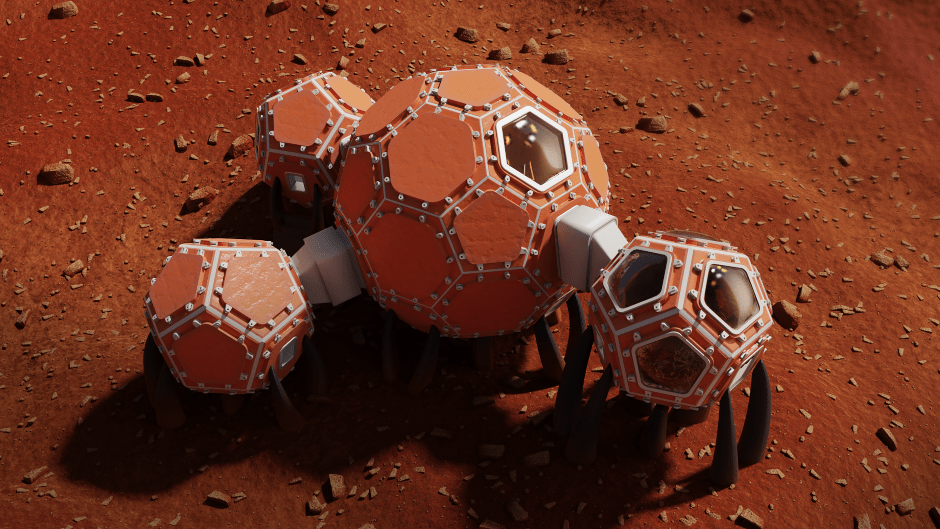

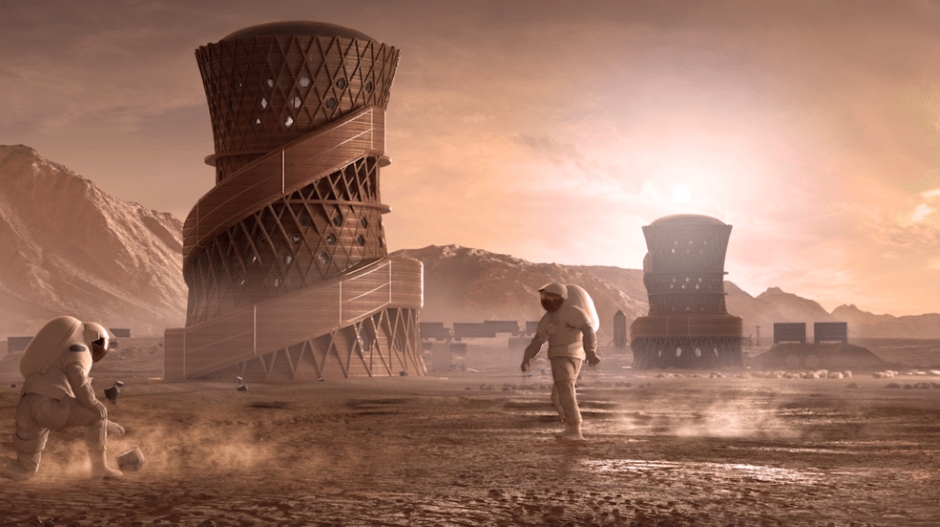

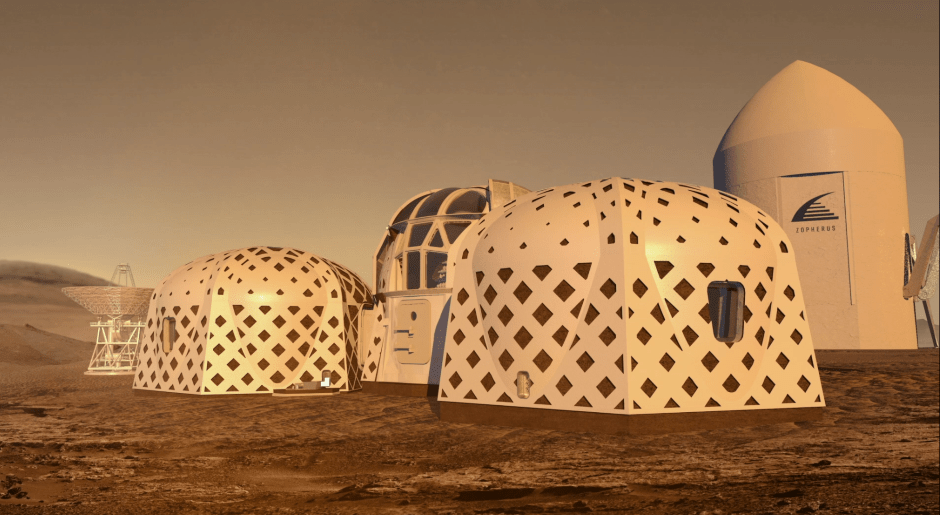

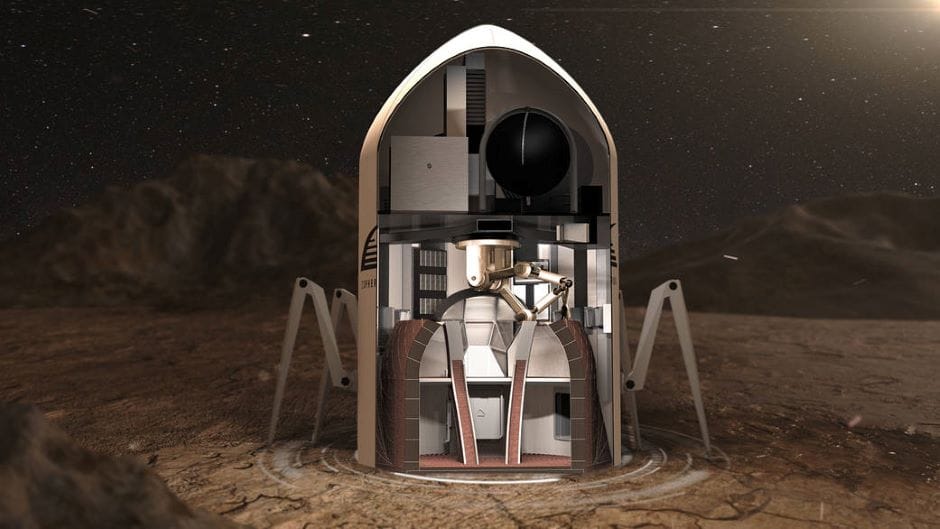

NASA, meanwhile, made construction of 3D-printed habitats on Mars the subject of a competition, which completed its penultimate and fourth phase in April. The top three teams to enter the competition, New York-based SEArch+/Apis Cor, Zopherus from Arkansas, and Mars Incubator of New Haven, Connecticut, shared a $100,000 prize purse based on short videos and miniature 3D printed models to show the interiors of their structures.

Each team took a different approach to the problem. SEArch+/Apis Cor developed a multi-storey design with continuous structural reinforcement, thanks to its spiral structure and ports along the side on top of the building to allow in light; Zopherus used a roving 3D printer that is designed to move from site-to-site building additional structures; and Mars Incubator’s design consists of four separate volumes with different purposes, connected by bridges.

The final phase of the competition has been completed, with three finalists going head-to-head to build full-size models of their structures, but as this feature went to press, the winner (which will win an $800,000 prize), had not yet been announced.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...