With the recent success of the Rosetta and New Horizons missions, along with Tim Peake’s adventure on the ISS, space exploration seems to have regained a foothold in the public consciousness. Last month, The Engineer reported on NASA’s Orion programme, the Multi-Purpose Crew Vehicle that should herald a new era of manned space flight, with Mars the ultimate goal. Mars now seems tantalisingly within reach, and both ESA and NASA predict that humanity’s first steps on another planet will happen some time in the 2030s.

But while the technology to get there is reasonably well established, surviving on the red planet for any length of time will be a major challenge. Creating a long-term presence on the Moon or Mars will mean making use of indigenous resources, using native soil and rock to build structures and habitations. To do this, the challenges of manufacturing beyond our own planet will need to be met.

In-orbit manufacturing is the first step of that journey. As well as being a vital testing ground, manufacturing off-Earth also has a number of practical and economic advantages.

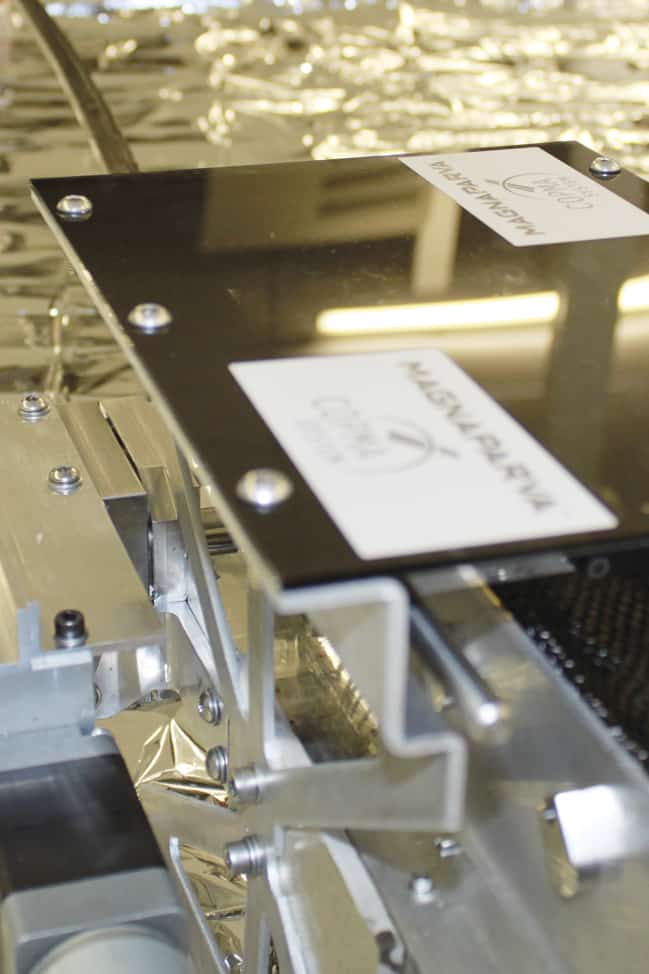

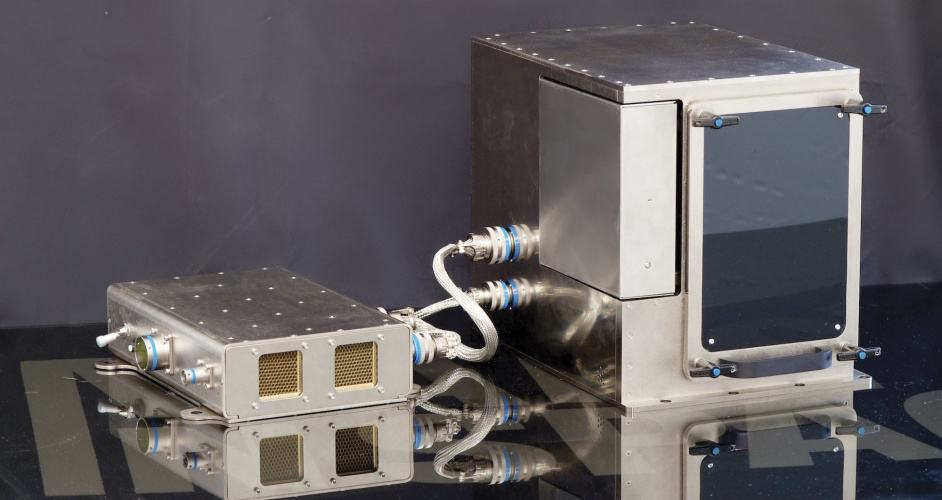

Although UK involvement in this nascent sector is limited, Magna Parva, based in Leicester, UK, has been developing its COPMA prototype since 2007. The system, which uses a form of miniaturised pultrusion, is designed to build large carbon-composite 3D structures in space. COPMA stands for Consolidated Off Planet Manufacturing and Assembly System for Large Space Structure.

“Really it’s a spin into the space industry of a common terrestrial technology,” Andy Bowyer, director and co-founder of Magna Parva, told The Engineer. “The technology itself is relatively elegant, in the sense that it’s not hugely complicated in terms of a manufacturing technology. There’s not a lot of elements or components in it, but it needs a fair amount to get it to work in a space environment, because that’s where the challenge is.”

That challenge includes variations in gravity, the vacuum of space, high levels of radiation, and temperature extremes. In the face of such obstacles, one may ask: why go to the trouble to manufacture in space? As usual, the answer can be found in the bottom line. Launching pre-fabricated structures is inevitably less efficient and more costly than launching the raw materials required to build them. By sending spools or containers of component materials and manufacturing in orbit, the cost of launches could fall dramatically.

“It’s a lot easier to fly raw materials to space than it is to fly a component that’s been folded up into 100 different levels,” said Bowyer. “So you can design the end component to only work with the end use requirements. Whereas if you’re designing a structure for end use in space now, you’ve got to design it to be used on Earth.”

A related benefit is that space-built structures no longer have to be designed to withstand launch. Anything sent into space has to endure the extreme forces associated with escape velocity. If it is built in orbit, that requirement disappears and further efficiency gains can be made.

“You’ve got to design it for the test environment, which is gravity and all those sorts of things,” Bowyer explained. “So it is, by its very nature, a more massive structure than is actually required by the end use. By designing your end structure to be specific for that, you reduce the mass significantly. Also, a roll of carbon fibre, a jar of resin, is a lot more compact than a component that has got lots of air around it and in between it.”

Terrestrial pultrusion devices tend to be room-sized machines, built for heavy industrial use. The challenge for Magna Parva is to miniaturise the technology to make it practical for operation in space. The only in-orbit environment to currently test this type of equipment is the International Space Station, so engineers tend to have it in mind when designing orbital manufacturing systems.

“We’ve got our prototype down to about the size of a shoebox,” Bowyer said. Future versions will be even smaller, he claims, as the prototype is gradually refined. COPMA’s current capabilities are limited to manufacturing, but Magna Parva is also looking at incorporating assembly into the system’s evolution. The plan is to embed elements such as copper wiring and fibre optics into the structures, and there are early-stage concepts for assembling multiple structures together. How soon we might see the system in action is a matter of funding, according to Bowyer.

“It’s always down to money ultimately,” he said. “If you can get the funding, the development itself is quite rapid, it’s probably only a couple of years. The challenge with space technology is not necessarily designing and building it. There are clever engineers around, we employ clever engineers and you can design and make stuff with the right budget. The challenge is how you get the flight opportunity. Who’s going to put it on whose spacecraft? Ideally, we’d like to go to the ISS, go as an experiment. It’s where most people get their first opportunities for new technology.”

“There’s a set process. We’re British, so we go through the European Space Agency. You get on to a programme, you lobby to get a slot. We’re doing all the appropriate lobbying at this point so that in a couple of year’s time we could be in a position to do it. But it’s highly competitive. There’s lots of people with good ideas, and it’s a very competitive marketplace, but that would be the ideal place for us to trial.”

Magna Parva’s ambitions certainly have precedent. Since 2014, the ISS has been equipped with a 3D printer designed and built by US company Made In Space (MIS). In December of that year, the crew of the space station printed a tool using a design file transmitted from Earth for the first time. The small ratchet wrench that was printed was subsequently returned to Earth for testing, but the exciting potential of printing on demand in space was confirmed.

“The main lesson was that it worked,” Brad Kohlenberg, business development engineer at Made In Space, told The Engineer. “We weren’t sure if extended microgravity and printing multiple times would work. We’d done it in little bursts through parabolic flights, but we had never had that extended microgravity kind of experience.”

It worked so well, in fact, that a considerably more advanced device will soon be joining it. The commercial-grade 3D printer, known as the Additive Manufacturing Facility (AMF), was due to be delivered to the space station last year. However, a string of ISS resupply failures means Made In Space is now looking at a March 2016 launch date. Initially, the AMF will only print polymers, but there are plans to adapt it in future to print with metals and other materials.

“It’s designed to be modular so we can actually swap out the plastic extruder for potentially a metal extruder,” Kohlenberg explained. “It has the ability to upgrade to do that, but right now it’s only going to be polymer.”

Assuming the AMF is delivered safely to the ISS, the added capability it will bring opens up interesting new scientific and commercial opportunities. In August 2015, MIS announced that it was teaming up with fellow US company NanoRacks to develop an orbital construction-and-deployment service for CubeSats. Called Stash & Deploy, the service will use a variety of components stored on the ISS to build custom CubeSats for customers. The plan is for many of these components to be built on board the space station using the AMF.

“You will have an inventory of commonly used space components on board,” said Kohlenberg. “Things such as radios, processors, gyroscopes – things that every CubeSat has.”

Developers on Earth will be able to look through this inventory, and rather than launching complete CubeSats, will only have to launch certain components. These will then be supplemented with stock from the orbiting inventory and integrated into 3D-printed structures, saving considerably on launch costs.

“Eventually you will integrate all those parts and pieces,” Kohlenberg added, “ideally in a really easy, almost snap-together Lego kind of fashion, and are left with this hybrid ‘3D printed/electronic components’ spacecraft.”

Made In Space’s plans don’t end there. In November 2015, the company secured funding from NASA to progress with Archinaut, a project that Made In Space said will deliver the first additive manufacturing, aggregation and assembly of large and complex systems in space without the aid of astronaut extravehicular activity.

It will be a free-flying spacecraft that is capable of 3D printing and assembling large structures in orbit, including antennae, booms, and even other spacecraft.

“Archinaut is definitely something that we’re really proud of,” said Kohlenberg. “It’s the realisation of the vision we’ve had since the beginning. We started [the company] thinking one day everything in space will be made in space, and we’ll be building these giant spaceships in space. But how do we get there?”

“So if 3D printing was one big step, this is kind of the next big step on that path to this overall grand vision. Now instead of inside the ISS with astronauts printing 3D-printed parts, you’re outside the station, completely autonomous, this robot is using robotic arms to 3D print struts and beams and using its arms to connect those beams together and building up scaffolding.”

Once this scaffolding is in place, electronic components could then be integrated and large capable structures could begin to take shape. While it may sound like borderline science fiction, amazingly, the initial stages are just a couple of years away, according to Kohlenberg.

“The timeline is about two years,” he said. “We’re getting the money from NASA later this year, and we hope to have the first demonstration of the overall programme in 2017.”

Looking even further ahead, concepts are already in place for space-based manufacturing on both the lunar and martian surfaces. In 2013, ESA revealed concepts it developed with architects Foster + Partners to 3D print a lunar habitation using regolith from the Moon’s surface. By using indigenous materials to create structures on other worlds, long-duration missions could one day become a reality. Unsurprisingly, it’s an area where Made In Space is also active, using simulated martian and lunar soil developed by NASA to carry out research.

“We’ve actually had some success using lunar regolith – lunar simulated soil – as well as martian regolith, and using that as 3D-printing feedstock,” said Kohlenberg. “They call it ISRU: In Situ Resource Utilisation. When we land on these planets, actually using the planets and the atmosphere of these planets themselves to be the resources that we use to create whatever we need in our surroundings.”

“We’ve done a lot of tests. We’re located at NASA Ames [a major NASA research centre in Mountain View, California] so we’ve actually been able to use some of NASA’s resources, and one of those resources is access to all this lunar regolith simulate.”

While technology has brought ISRU into the realms of possibility, there are still a few obstacles to clear before we start breaking ground on the first Moon bases. There are two main methods for printing with lunar regolith. One involves mixing it with some form of organic binder to create a cement-like substance that is then printed. The other is to melt the regolith using high-energy X-rays, essentially sintering the rock and printing it while still in a molten state. While the first method involves transporting large volumes of binding agent to the Moon – or perhaps even growing it there – the second involves huge quantities of energy. Each presents unique challenges.

“The technology is here and now,” Kohlenberg said. “We can do this. It’s just figuring out the cost-benefit analysis of doing it – does it actually make sense? I think it does make sense, but if we are going to do it, we’re probably going to have to make some automated systems, because either way you look at it it’s going to be a slow process. So what we want to do is throw these robots on the planet and just have them going 24/7, building out these infrastructures so that by the time we put boots on the ground we have roads and landing pads and structures and habitats waiting for them.”

***

For additional information on off-earth manufacturing you can visit Magna Parva's recently launched microsite inspacemanufacturing.com

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...