The Spherical Tokamak for Energy Production (STEP) project, which aims to design a power station fired by nuclear fusion, has announced another new collaborator, with France-based contractor Assystem coming on board to provide designs for a key component of the fusion system and services that will help other collaborators deliver the project.

STEP is a UK government-proposed project to take a lead in the development of fusion. In early October, the government announced a £200m investment to develop the concept behind STEP, which is to use a spherical Tokamak to perform and manage nuclear fusion and harness the heat produced to generate electricity. The ambitious goal for the project is to have a power station – which would be the first fusion unit – sending electricity to the grid by 2040.

_______________________________________________________________________

Further reading

- Beyond ITER – next steps in fusion power

- Interview: Jonathan Carling, Tokamak Energy’s new CEO

- Tokamak Energy hits 15 million degree fusion milestone

_______________________________________________________________________

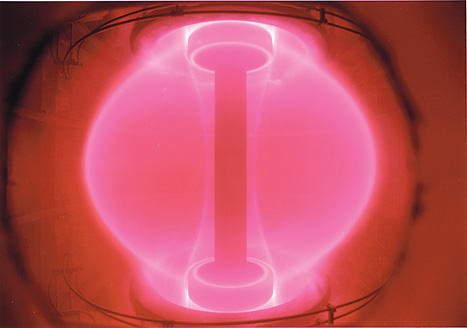

Spherical Tokamaks are part of a family of reactor designs that generate nuclear fusion by heating and compressing plasma (a gas formed of charged particles) using electromagnetic technologies. They are, to date, the most successful kind of fusion reactor, with the Joint European Torus (JET) located at Culham in Oxfordshire, the current record-holder for fusion energy production, although like all fusion reactors, it has not yet produced more energy than it takes to generate fusion. While conventional Tokamaks like JET, and the ITER reactor currently under construction in the south of France, are shaped like ring doughnuts, spherical Tokomaks resemble cored apples and produce a more stable plasma which the design’s proponents believe will be easier to manage and would allow energy to be produced from a smaller and therefore cheaper reactor.

This technology has also been pioneered at Culham, with the Mega Ampere Spherical Tokamak (MAST) being the first operational reactor of this type. A company spun off from the MAST team, Tokamak Energy, is developing the technology and working on a succession of reactors, increasing in scale. STEP is a continuation of this project.

Assystem has announced that its UK operations, based in Sunderland, Blackburn and Derby, will develop designs for a breeder blanket for the STEP reactor. This component lines the reactor interior and performs two functions: it extracts the heat from the reactor so that it can be used to raise steam, and it captures the fast neutrons generated by the fusion reaction (where the nuclei of two heavy isotopes of hydrogen, deuterium and tritium, are forced together to form a helium nucleus with the release of energy) and multiplies them so that they can generate tritium through a further reaction with lithium nuclei. It will also gather and scrutinise information generated from the testing of materials in different parts of the STEP reactor to produce a materials database that, it says, will be key in assessing the theoretical performance and manufacturing readiness of a new nuclear fusion reactor. Moreover, it will provide a detailed review of the STEP programme’s current delivery tools, processes and procedures to help produce a set of recommendations based upon its own digital asset management experience.

While the reactor itself is being developed by UKAEA at Culham, Assystem’s contribution will be delivered from its locations in the North and Midlands. The Sunderland site is already involved in fusion development, as it is leading the design of a robotic device to handle components of ITER while the reactor is in operation.

"With global dialogue on reducing carbon emissions becoming an urgent priority, we commend the nation’s commitment to investing in the development of fusion energy and are proud to be associated with STEP. We firmly believe this project has the potential to help the nation take a giant leap towards achieving its net zero targets. We are also positive that bringing Assystem’s learnings and expertise from working on ITER will help us in creating a functional, strong and steady plant,” commented Kevin Wilkinson, business unit director at Assystem.

Assystem joins Frazer Nash on the STEP team. In November, the company announced that it would design the diverter for the STEP reactor; this component, which runs around the base of the reactor interior, handles the highest heat loads as is the only point where the plasma actually comes into contact with the reactor. Frazer Nash’s contribution, which leverages its expertise with heat exchanger technologies, is aimed at ensuring the components can be easily produced for a commercial power station.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.