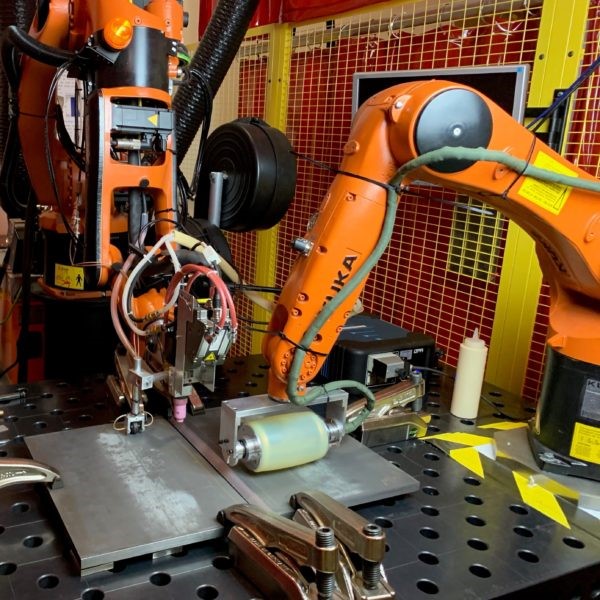

The Automated Welding Equipment System Inspection and Monitoring project (AWESIM) will see the development of an integrated package of machine learning, sensor technology and advanced remote manufacturing processes to deliver welding, weld inspection and potentially weld certification all in near real time.

The work, which is being led by Babcock’s civil nuclear business Cavendish Nuclear, along with some of the UK’s most renowned engineering and academic institutions – is being driven by urgent UK industry targets to achieve a 30 per cent cost reduction in nuclear new build along with savings of 20 per cent in nuclear decommissioning projects by the year 2030.

The first phase of the project will receive £1.3m of funding through the BEIS’ Energy Innovation Programme, whilst the remainder of the funding will come from industrial partners.

Jon Hall, Managing Director of Technology at Babcock said: “Babcock is a technology-led business driven by engineering insight. Advanced manufacturing is a core part of our offering, given the complex and critical assets we manage. We’re delighted to have secured the confidence and funding of UK government to lead this innovative project which will add value across our customer base.”

MORE FROM THE ENGINEER

UK nuclear sector calls for quick decision on new power stations

Tony Burnett, Head of Innovation and Technology for Cavendish Nuclear added that whilst AWESIM has initially been developed for the nuclear sector, its capabilities will be applicable to any industry developing large scale critical assets involving high-integrity welding processes.

A large, factory scale demonstrator to showcase the integrated technologies will be built at the University of Sheffield’s Nuclear Advanced Manufacturing Research Centre later this year.

The University of Strathclyde’s Advanced Nuclear Research Centre will also develop a non-destructive examination system with Derbyshire engineering company Peak NDT as part of the project.

Cavendish Nuclear, working in collaboration Doosan Babcock, will provide engineering expertise to ensure the technology is industry-ready.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...