The AR tool in use today will help with the construction of the car’s monocoque, specifically with the application of carbon fibre laminates. The application process is conducted over an intense week-long period with students from Team Bath Racing working in shifts, applying each pre-cut carbon fibre laminate in the correct location. To ensure maximum strength and rigidity for the final product, the weave and direction of each laminate must vary according to a predetermined pattern.

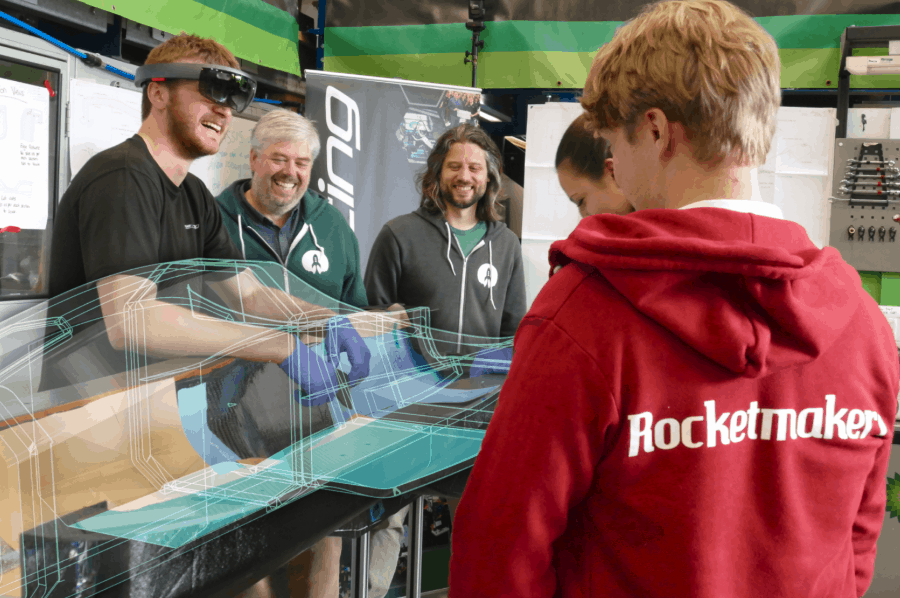

Designed by Rocketmakers, the tool creates an AR version of the car monocoque, with the correct shape, location, and orientation of each segment visible to the wearer during the application process. It is expected to provide users with a much-improved work experience and accuracy rate than current methods.

While carbon fibre laminates are typically applied by robots in production vehicles, their application in small-scale production is generally one of the more physically and mentally demanding parts of building bespoke vehicles. According to Bath, current state-of-the-art - even for Formula 1 car construction - consists of placing a computer screen nearby and ‘eyeballing it’.

“After you’ve spent most of a year designing a car, the week-long process of carbon fibre layup is really nerve-racking,” said Jack Harris, Team Bath Racing 19 Business Manager and MEng(Hons) Mechanical with Automotive Engineering student at the University of Bath.

“We’ve been talking to Rocketmakers for months to determine where the best use of AR technology would be for assisting car construction. Carbon fibre layup is definitely one of those jobs that, despite the high tech equipment we use for our design and testing, still relies mostly on hand-eye coordination. Having a tool to assist with the stressful, backbreaking process is really exciting.”

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.