Professor Saffa Riffat is leading a research team at Nottingham University in the development of the self-contained and long-lasting ‘cold pack’ that can be used with PPE in healthcare settings or patients on ventilators, as well as the public wearing face masks.

CLICK HERE FOR MORE ON THE ENGINEERING RESPONSE TO COVID-19

The COVID-19 pandemic has seen a huge rise in the use of PPE, which can cause heat stress for those having to wear it for extended periods. Similarly, COVID-19 patients often display a high temperature, a situation that can be worsened if required to be put onto a ventilator in poorly ventilated or poorly air-conditioned hospital wards.

According to Riffat, conventional cold packs are ill-suited for Covid-19 situations because of their design complexity, lack of versatility, high unit cost, poor manufacturability, and recyclability.

“We have two types of BeCool,” he told The Engineer. “[A] self-cooling one and another one you can place in a refrigerator. However, both are reusable. We can design the BeCool [to] last two hours or more, but the pack can easily be replaced with another one.”

Riffat added that a BeCool Pack uses a multi-cell bio-polymer structure containing an endothermic composite chemical agent such as urea/ammonium chloride that is separated from water cells. The fast and controllable cooling effect is achieved through rupturing the seal between the cells. By activating some cells to provide cooling and later activating more cells to provide further cooling, the generated cooling and temperature can be controlled depending on the end-user’s demand, he said.

BeCool Packs are said to be free from harmful chemicals, using water or combined with a urea-based endothermic material, which is a natural biochemical substance, non-toxic, and biodegradable. Similarly, biopolymer materials are proposed for encapsulating BeCool Packs.

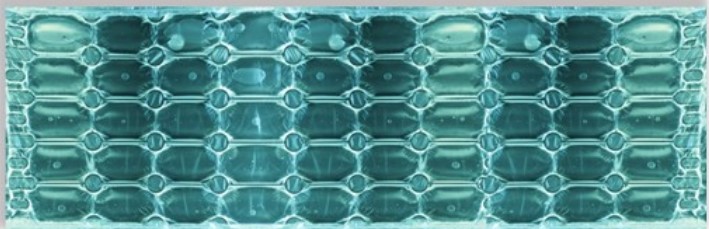

Riffat said the packs can be manufactured in long chains akin to bubble wrap and easily cut into sections, bringing down costs compared to conventional cold packs. Heat-sealing can be used to form two watertight envelopes for loading predetermined amounts of endothermic material and water. The packs can be made to insert into clothing such as aprons and masks or made into blankets to lower body temperature and provide cooling for COVID-19 patients during transportation, Riffat said.

“The optimum temperature is about is about 8oC,” he said. “It will take about 45-60 minutes to reach ambient temperature.”

The university is working with phase change materials specialists PCM ltd and packaging company KMD Company ltd in the development and commercialisation of the patented BeCool technology.

Viking Link connects UK and Danish grids

These underwater links must, based on experience with gas pipelines, be vulnerable to sabotage by hostile powers. Excessive dependency on them could...