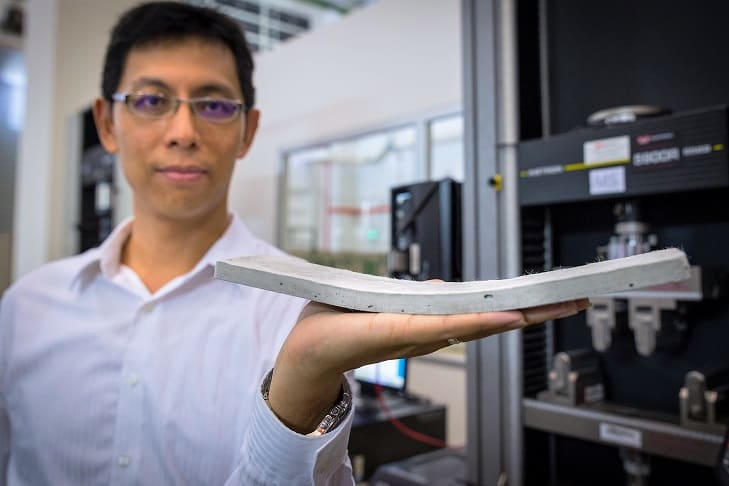

Scientists from Nanyang Technological University (NTU) in Singapore have developed a new type of bendable concrete that they say could reduce maintenance and speed up construction work.

Known as ConFlexPave, the material is formed from the regular concrete components of cement, water, gravel and sand, combined with polymer microfibres. The addition of the synthetic fibres allows the concrete to flex under tension, making it at least twice as strong as traditional concrete when subjected to bending forces.

According to assistant professor Yang En-Hua from NTU’s School of Civil and Environmental Engineering, understanding how the various components interacted with each other at a microscopic level was crucial.

“With detailed understanding, we can then deliberately select ingredients and engineer the tailoring of components, so our final material can fulfil specific requirements needed for road and pavement applications,” he said.

The researchers say that ConFlexPave is designed to be precast in slabs for quick installation, halving the time required for roadworks and new paving. As well as providing the concrete with flexibility, the polymer microfibres have the added benefit of providing skid resistance, making it safer to both walk and drive on.

“The hard materials give a non-slip surface texture,” Yang explained, “while the microfibres which are thinner than the width of a human hair, distribute the load across the whole slab, resulting in a concrete that is tough as metal and at least twice as strong as conventional concrete under bending.”

So far, the bendable concrete has only been tested in tablet-sized slabs at NTU’s laboratories. The next phase will see real-life testing taking place in locations around the university campus over the next three years, to see how the material holds up to both pedestrian and vehicle traffic.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...