A simple bleach treatment restores the composite fabric to its original state after exposure to biological or chemical threats, making it a promising candidate for face masks and other protective clothing.

“Having a bifunctional material that has the ability to deactivate both chemical and biological toxic agents is crucial since the complexity to integrate multiple materials to do the job is high,” said Northwestern’s Omar Farha, an expert in metal-organic frameworks (MOFs) that underpin the technology.

Farha, a professor of chemistry in the Weinberg College of Arts and Sciences, is a co-corresponding author of the study.

The MOF/fibre composite builds on an earlier study in which Farha’s team created a nanomaterial that deactivates toxic nerve agents. With some small manipulations, the researchers were able to incorporate antiviral and antibacterial agents into the material.

Metal-organic framework materials show promise for fuel cells

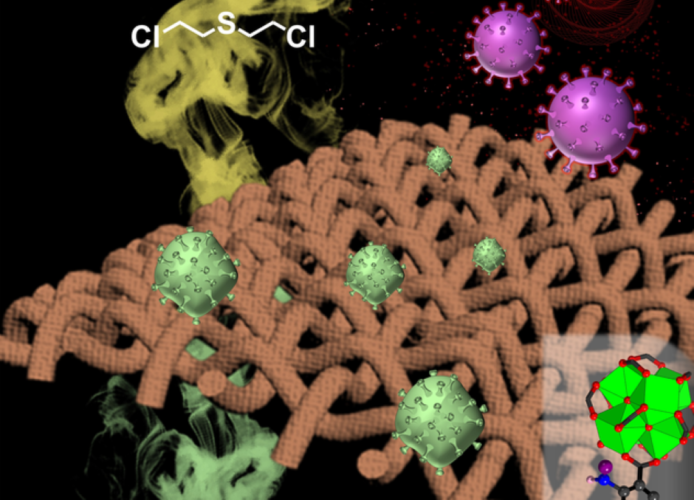

Nano-sized MOF materials are designed with a lot of holes that can capture gases, vapours and other agents. In the new composite fabric, the cavities of the MOFs have catalysts that can deactivate toxic chemicals, viruses and bacteria. The porous nanomaterial can be easily coated on textile fibres.

The study was published recently in the Journal of the American Chemical Society (JACS).

The researchers found that the MOF/fibre composite exhibited rapid activity against SARS-CoV-2 and gram-negative bacteria (E. coli) and gram-positive bacteria (S. aureus). Also, the active chlorine-loaded MOF/fibre composite rapidly degraded sulphur mustard gas and its chemical simulant (2-chloroethyl ethyl sulphide, CEES). The nanopores of the MOF material coated on the textile are wide enough to allow sweat and water to escape.

In a statement, Farha said the composite material is scalable as it only requires basic textile processing equipment currently used by industry. When incorporated into a facemask, the material should be able to protect the mask wearer from virus as well as protecting individuals who come into contact with an infected person wearing the mask.

According to Northwestern, the researchers also developed an understanding of the material’s active sites down to atomic level, allowing them and others to derive structure-property relationships that can lead to the creation of other MOF-based composites.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...