Micro-actuators are devices that convert signals and energy into mechanically driven movement in small-scale structures. Used in a range of advanced microscale technologies, they usually rely on external changes in bulk properties such as pH and temperature to trigger repeatable mechanical transformations.

The new study, published in Nature Chemistry, highlights a novel approach using internal changes as the trigger for signal-based movement.

Researchers from Bristol’s School of Chemistry, the Max Planck Bristol Centre for Minimal Biology (MPBC) and the Bristol Centre for Protolife Research said they successfully embedded tens of thousands of artificial cell-like entities (protocells) within helical filaments of a polysaccharide hydrogel to produce tiny free-standing springs that are chemically powered from within.

Moving hydrogels have potential for soft robotics and artificial muscles

Soft robotics actuators are "fast as a hummingbird, strong as an elephant"

The team loaded the protocells with urease, an enzyme that generates carbonate ions when supplied with urea, then captured the artificial cells in a twisting jet of calcium alginate hydrogel using a home-built microfluidic device.

According to the study, the helical filaments start to uncoil in water when the urease is switched on and the speed of the lengthwise extension increased as more carbonate ions escaped from the protocells into the surrounding hydrogel.

The coupling of endogenous chemical activity to mechanical movement was associated with the breaking of crosslinks in the hydrogel due to removal of the calcium ions by on-site formation of calcium carbonate particles, leading to slow release of elastic energy in the spring-like microstructures.

Researchers said that reclaiming the calcium ions by dissolving calcium carbonate particles using a second population of acid-producing glucosde oxidase-containing protocells placed outside the filaments reversed the uncoiling and re-established the original helical pitch of the free-standing springs.

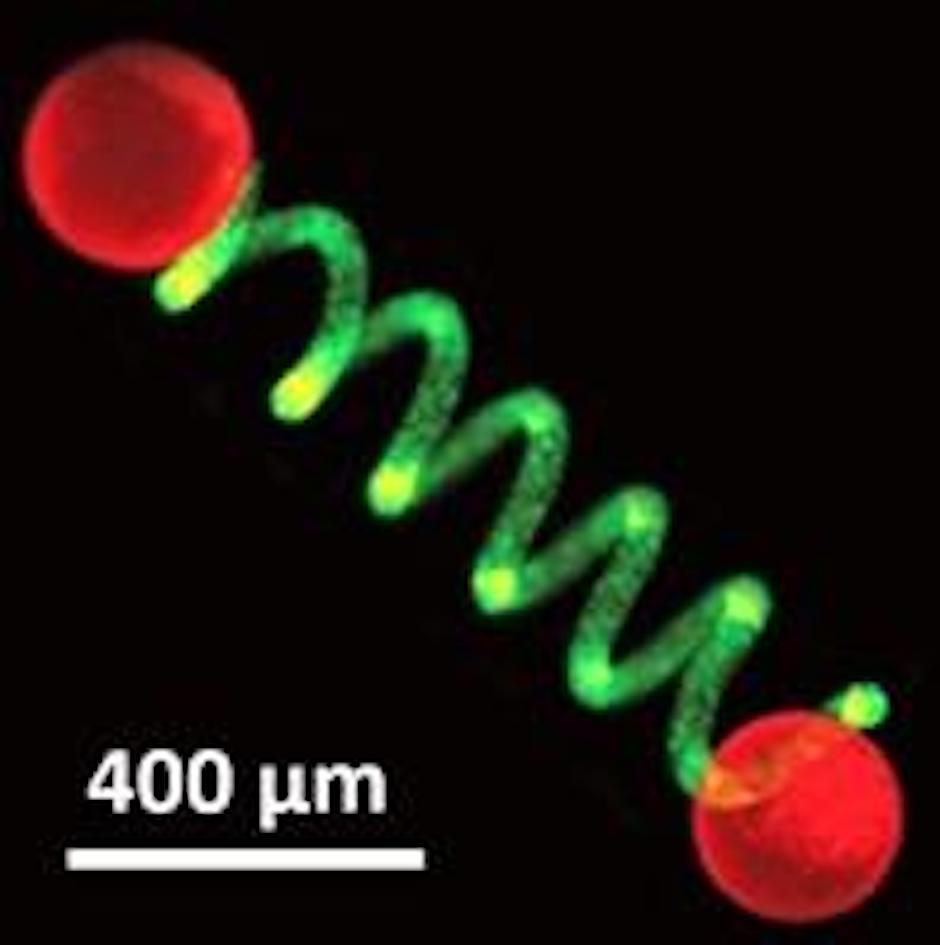

Based on this, they used the helical protocell filament as a drive shaft for performing protocell-powered mechanical work by attaching a single ‘giant’ protocell at each end of the coiled hydrogel and exploiting the tiny dumbbells as free-standing micro-actuators.

Urease activity in the two giant protocells was sufficient to cause a lateral extension of the dumbbell, the team said. The movement could be curtailed if one of the attached giant protocells contained glucose oxidase, which worked to restore the lost calcium in the hydrogel connector. A range of modes of chemical-mechanical transduction could be programmed into the micro-actuators by on-board processing of chemical signals.

“We have a longstanding interest in protoliving technologies,” said professor Stephen Mann, co-director of the MPBC. “One key challenge is how to interface protocell communities with their environment to produce functional relationships. The new work provides a step in this direction as it illustrates how endogenous chemical processes can be coupled to their energised surroundings to produce a programable chemo-mechanical micro-system.”

Dr Ning Gao, also at the MPBC and Bristol’s School of Chemistry said the team hopes its approach will motivate fabrication of new soft adaptive microstructures that operate via increased levels of autonomy.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.