The discovery, which appears in Applied Physics Letters, is said to offer more potential applications for the strong, lightweight nanotube fibres developed by the Rice lab of chemist and chemical engineer Matteo Pasquali.

The lab introduced the first practical method for making high-conductivity carbon nanotube fibres in 2013 and has since tested them for use as brain implants and in heart surgeries.

The research could help engineers in streamlining materials for airplanes and spacecraft. Increased interest in wearables like wrist-worn health monitors and clothing with embedded electronics could benefit from strong, flexible and conductive fibre antennas that send and receive signals, Pasquali said.

The Rice team and colleagues at the US National Institute of Standards and Technology (NIST) developed a ‘specific radiation efficiency’ metric to judge how well nanotube fibres radiated signals at the common wireless communication frequencies of 1 and 2.4 gigahertz and compared their results with standard copper antennas.

They made thread comprising from eight to 128 fibres that are about as thin as a human hair and cut to the same length to test on a custom rig that made comparisons with copper practical.

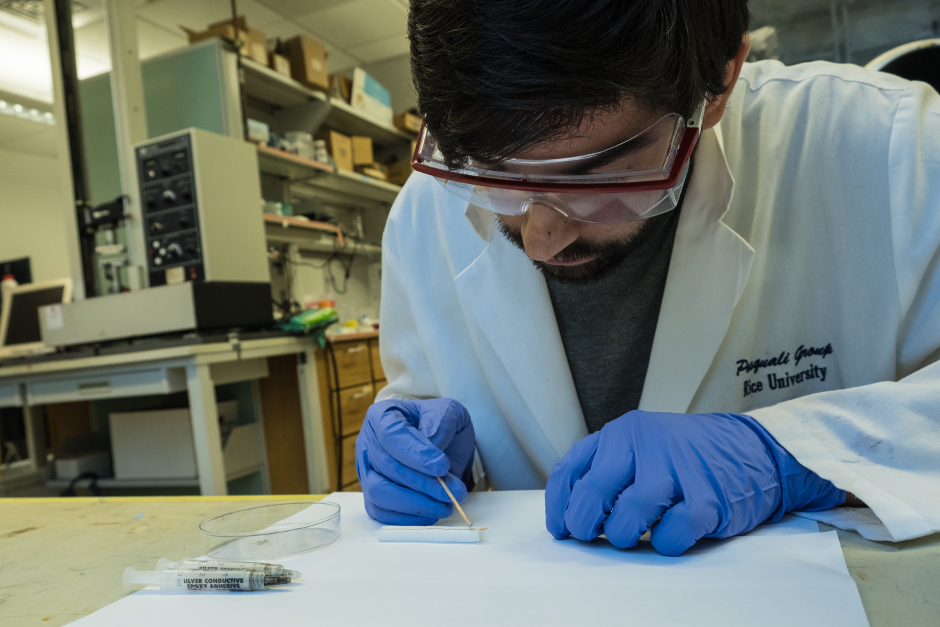

“Antennas typically have a specific shape, and you have to design them very carefully,” said Rice graduate student Amram Bengio, the paper’s lead author. “Once they’re in that shape, you want them to stay that way. So one of the first experimental challenges was getting our flexible material to stay put.”

The Rice researchers found the fibre antennas matched copper for radiation efficiency at the same frequencies and diameters. Their results support theories that predicted the performance of nanotube antennas would scale with the density and conductivity of the fibre.

“Not only did we find that we got the same performance as copper for the same diameter and cross-sectional area, but once we took the weight into account, we found we’re basically doing this for 1/20th the weight of copper wire,” Bengio said.

“Applications for this material are a big selling point, but from a scientific perspective, at these frequencies carbon nanotube macro-materials behave like a typical conductor.” Even fibres considered “moderately conductive” showed superior performance, he added.

Although manufacturers could simply use thinner copper wires instead of the 30-gauge wires they currently use, those wires would be very fragile and difficult to handle, said Pasquali.

“Amram showed that if you do three things right — make the right fibres, fabricate the antenna correctly and design the antenna according to telecommunication protocols — then you get antennas that work fine,” he said.

“As you go to very thin antennas at high frequencies, you get less of a disadvantage compared with copper because copper becomes difficult to handle at thin gauges, whereas nanotubes, with their textile-like behaviour, hold up pretty well.”

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?