Seattle-based EnerG2 has been awarded $21.3m (£12.8m) in funding from the US Department of Energy, which it plans to use to help it build a facility to produce nano-engineered synthetic carbon electrode materials.

EnerG2 will partner with Oregon Freeze Dry, one of its existing manufacturing partners, in the construction of the new plant, which will be located in Albany, Oregon.

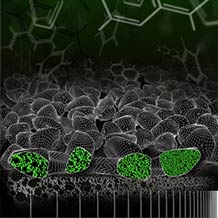

Working in collaboration with the University of Washington's Department of Materials Science and Engineering, EnerG2 has developed unique sol-gel processing technologies to help it make the carbon materials. The materials are extremely conductive and are attractive to electrolytic ions, methane, natural gas and hydrogen.

Sol-gel processing is a chemical synthesis that gels colloidal suspensions to form solids through heat and catalysts. EnerG2 has invented a means to control the hydrolysis and condensation reactions within the gelling process, allowing the materials' surface structures and pore-size distributions to be shaped, moulded and customised for a variety of energy-storage uses.

Most commercially available materials for energy storage are produced from naturally occurring precursors. Therefore, much of the performance of these derivative materials is determined by the natural physical properties of the selected precursor.

As a result, important characteristics such as pore size distribution and purity are fixed within the natural precursor and are merely exposed by competitors’ various processing approaches.

But EnerG2 claimed that its building of its energy-storage materials from scratch allows it greater structural control of the material and improved product purity.

Over the past year, EnerG2 has raised a total of $11m in financing from established cleantech investors including OVP, Firelake, Yaletown, and WRF Capital.

The patented and proprietary technology used by EnerG2 is based on molecular self-assembly and produces nano-structured carbon materials that are finely controlled and offer ultra-high surface areas

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.