Cars made from spot welded steel and aircraft made from riveted aluminium have involved manufacturing technologies which have served their industries well for decades. Contrary to popular belief however, both the aero and auto industries are surprisingly material agnostic and are solely driven by balancing the three key elements of weight, cost and functional performance.

Whether the challenge is for greater fuel efficiency or emissions reduction, or whether your vehicle is fossil fuelled, or electrically powered, keeping “m” (mass) as low as possible in Newtonian calculations, has become the norm for today’s engineers. As a result we have seen the emergence of aluminium intensive cars, carbon fibre composite aircraft and the new manufacturing processes that these drive have now become ubiquitous in the UK.

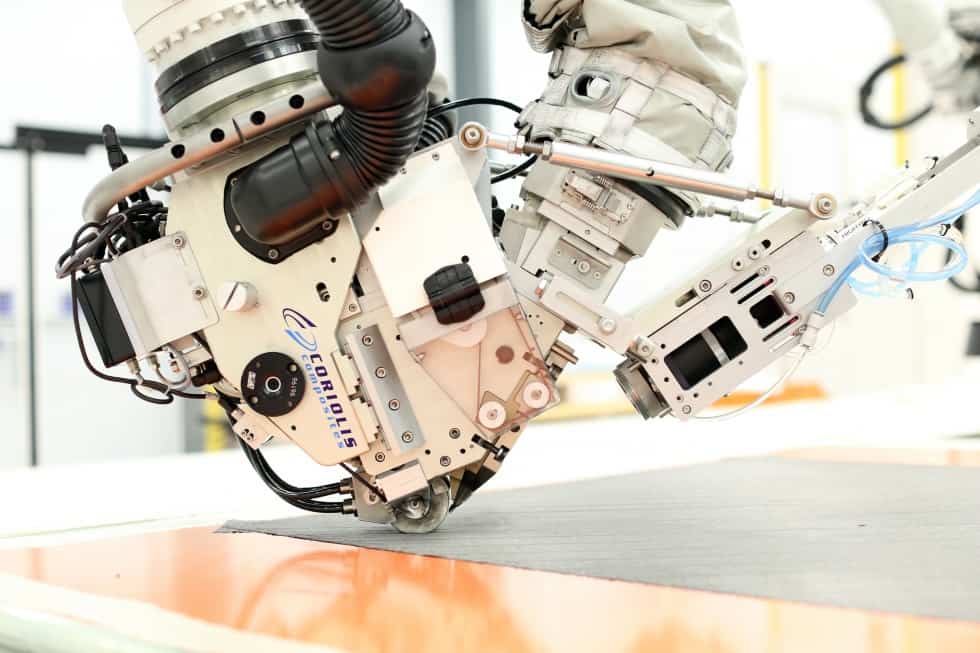

There is no doubt that advanced carbon fibre composite materials score well on performance, strength and weight but the challenge thus far has been on cost of the material and the time and cost in the manufacturing process.

There is a lot at stake, so we need to address this challenge now. In the UK alone, the market for affordable composites for the automotive industry is predicted to grow from a current value of approximately £300m to over £3bn in 2030, whilst the total global market could be worth £80bn.

In my role as chairman of the Automotive Council’s Manufacturing Group we have recognised this opportunity and realising it has become one of our key projects.

We’ve established that there is very real appetite for affordable structural composites if we can overcome the process and technical barriers, and cost of materials.

To this end, working with the Composites Leadership Forum and the National Composites Centre in Bristol - part of the High Value Manufacturing Catapult - we have scoped out a national plan showing what technology and supply chain capability the UK requires to succeed in this market. The elements of the plan cover everything from the development of materials to the final forming of the components using processes such as Resin Transfer Moulding.

Together, we have established the new ‘Affordable Composites Group’ (ACG). The ACG was set up to proactively facilitate the development of UK technology capability and supply chain capacity to deliver high productivity manufacturing of globally competitive, higher volume composite structures and components.

This collaboration is a prime example of industry taking the lead in identifying gaps in the current supply chain and proposing (funding) measures to address those gaps. Already, through collaborative projects, we have shown at the National Composites Centre that we can produce complex forms such as the floorpan, demonstrating high productivity, component integration and weight reduction potential of using composites in automotive applications.

Indeed, a programme of this scale can only be achieved through collaboration. We have brought 14 companies together with CR&D competition funding and 5 research partners to the tune of over £11Mm which has been supported by Innovate UK and the Office for Low Emissions vehicles.

If carbon fibre composites can be made to work for the car industry, there are very obvious and real benefits to spin back into aerospace and also into sectors such as the construction industry, rail and marine.

The programme is not just about developing the technology, it’s about giving the UK a chance to develop a valuable new supply chain for these materials. The UK was the first to produce a carbon fibre Formula 1 car and the first to produce a composite road car. We have a dynamic industry in the application of carbon fibre for aircraft with serious presence from Airbus, Rolls-Royce, Bombardier and their supply chains. I am therefore determined that we make the best use of our inherent technological capability.

Why this sense of determination? Well, I speak from experience. In my days leading car programmes I found myself at the helm of Engineering at Jaguar Cars at a time when my team were transitioning from steel based cars to the aluminium bonded and riveted construction which is now at the heart of the JLR brand.

The transition, although tough to manage was a great and enduring technical success. My only disappointment however was that the UK supply base did not respond to the new opportunity and step up the exploit it. As a result, much of the aluminium sheet, casting and extrusions had to be sourced from overseas.

We are poised to make a step change to the next generation of lightweight materials if the National Project can be made a success. Many industries will benefit and it will create new markets for British based engineering and manufacturing technology. I’m determined that this opportunity will not pass us by…

Dick Elsy is the Chief Executive of the High Value Manufacturing (HVM) Catapult

HVM Catapult is an official sponsor of The Engineer's Collaborate To Innovate awards

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...