Earlier this month, long-awaited plans were released to build the UK’s first new coal-fired power station since the 1970s. But unlike its polluting predecessors, if approved, the plant at Hunterston in Ayrshire will integrate carbon-capture and storage (CCS) technology – a process that many believe is absolutely key to solving the world’s carbon-emission problems.

The Ayrshire proposal is the first application made since the UK government enforced rules stating that all new plants must be fitted with CCS, a technology that captures CO2 and buries it deep beneath the ground. The developer behind the proposal, Peel Energy, claims that the facility could provide enough energy to power up to three million homes, while creating up to 1,600 jobs and storing 90 per cent of the carbon dioxide produced.

“In the UK alone, the sector could be worth more than £3bn a year and is estimated to sustain between 70,000 and one million jobs by 2030.”

Jeff Chapman, CCSA

The environmental and economic benefits in Ayrshire could be seen on a larger scale if the government is able to implement its CCS strategy throughout the UK. The process is increasingly being viewed as the best chance for the UK to reach its carbon-emissions targets and the race is now on to develop the technology.

Prior to the election the government passed the Energy Act, which provided the largest statutory investment in CCS made in any country in the world. But environmental concerns weren’t the only catalyst behind Westminster’s massive funding programme. A report released earlier this year outlined the case for CCS investment, stating that countries and companies who develop CCS first will be the ones who have the advantage in a global growth industry.

In the UK alone, the sector could be worth more than £3bn a year and is estimated to sustain between 70,000 and one million jobs by 2030. Jeff Chapman, chief executive of the Carbon Capture and Storage Association (CCSA), believes the potential market for CCS is huge. ’It has become clear that you cannot deal with climate change without a large proportion of CCS,’ he said. ’We’ll be facing a situation where we are going to have to invest very many billions of dollars worldwide.’

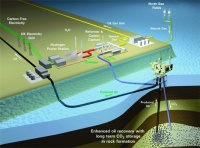

And it seems that the UK is well placed to benefit from that investment. Access to depleted gas and oil fields in the North Seas means that the UK, along with Norway, has some of the best storage sites in Europe. It also has transferable skills in the offshore oil and gas, petrochemical and power industries, where transportation by pipeline and effective storage techniques mean that much of the same skills can be used to get a head start on CCS.

’This is key to being at the fore of CCS,’ said Jon Gluyas, professor in CCS and Geo-Energy at Durham University. ’Most of the equipment for that is home designed, if not always home produced, and we know how to put the components together. I am sure it would be a fillip for the manufacturing sector if it can move swiftly and deliver high-specification components.’

But, while experience in the oil and gas industry is likely to hold the UK in good stead, the country’s research base will be equally important in developing new skills specific to the CCS industry. One problem facing engineers is estimating the available storage capacity in relation to issues such as porosity, permeability and the fracture strength of rock. The current range of capacity estimates varies widely because of the lack of data on saline aquifers.

“We have a huge challenge from an engineering point of view… It’s important that the government gets started soon.”

Jon Gibbins, Edinburgh University

’A lot of the basic skills are in place from the oil and gas industry, but putting material back in the ground is not quite the same,’ explained Gluyas. ’We will be inflating the subsurface rather than deflating it. CO2 is an acidic fluid that will react with the minerals in the subsurface. Monitoring is a whole new area in which to develop skills, be it during injection or after the sites are shut in. Also, on the transport side, we need to able to move off-spec CO2 in pipelines – this will require further technological developments.’

Jon Gibbins, a lecturer in power-plant engineering at Edinburgh University, believes that the country needs to act now. ’We have a huge challenge from an engineering point of view,’ he said. ’To go from nothing to having 5GW of CCS in 10 years, which is what the government wants, is actually quite a lot when you’re doing it for the first time. It’s important that the government gets started soon, because everything takes longer than you think. It’s proven technology, its just a case of getting out there and showing that it can be done at a very large scale.’

“Someone needs to push this across the line. The first projects are pioneering, equal to bringing ashore the first North Sea oil.”

Jon Gluyas, professor in CCS and Geo-Energy at Durham University

The UK is supporting the construction of four commercial-scale CCS projects that aim to demonstrate established CCS techniques, as well as explore less advanced processes, such as oxy-fuel capacitor technology. But many experts believe that the government needs to do more to take over the strategy for CO2 transport and storage.

Gluyas said: ’Someone needs to push this across the line. The first projects are pioneering, equal to bringing ashore the first North Sea oil. In a volatile market, the initial investments will not be made. Our monitoring has to be outstanding. One major CO2 leak could put us back decades if the public determines that the industry has been irresponsible.’

Responsibility is one issue that is still under contention. Unlike the BP Deepwater Horizon oil leak, any CO2 leaks will be the responsibility of the government, according to Gibbins. ’The chance of anything happening is very low but, if it does, it’ll be centuries away and, actually, no companies will be there to sort that out. Given that the liability will ultimately rest with a government, there is actually a strong argument that, just to preserve its own risk, it has got to oversee its own storage.’

Despite the challenges and risks for getting CCS underway, the geological and intellectual position of the UK means that CCS could provide a major boost to British engineering and make the UK a global leader in addressing climate change.

’The opportunities will help the engineering industry pick up from where it is now,’ said Chapman. ’If I was a teenager thinking forward in terms of career, I’d be thinking that the world of energy is going to be a very exciting area. There’s going to be a lot of work to be done in the future and I think it makes for quite a safe and lucrative life for engineers in Britain.’

Indepth

Oxy-fuel

Oxy-fuel capacitor technology involves firing a conventional coal-fired power-station boiler with oxygen and recycled exhaust gases, instead of regular air. The process produces a concentrated stream of CO2 that can be captured and stored beneath the ground. The technology was used in a pilot CCS power plant at Schwarze Pumpe, the first carbon-capture plant in the world, and there have also been a number of demonstrations using pilot-scale facilities in the US, Europe, Japan and Canada. But there are a number of technical barriers to deployment, including improving the technology for air separation needed to produce oxygen, which currently demands a lot of energy. The UK has said that it has not ruled out using oxy-fuel on a commercial-scale project if a company is prepared to get involved.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...