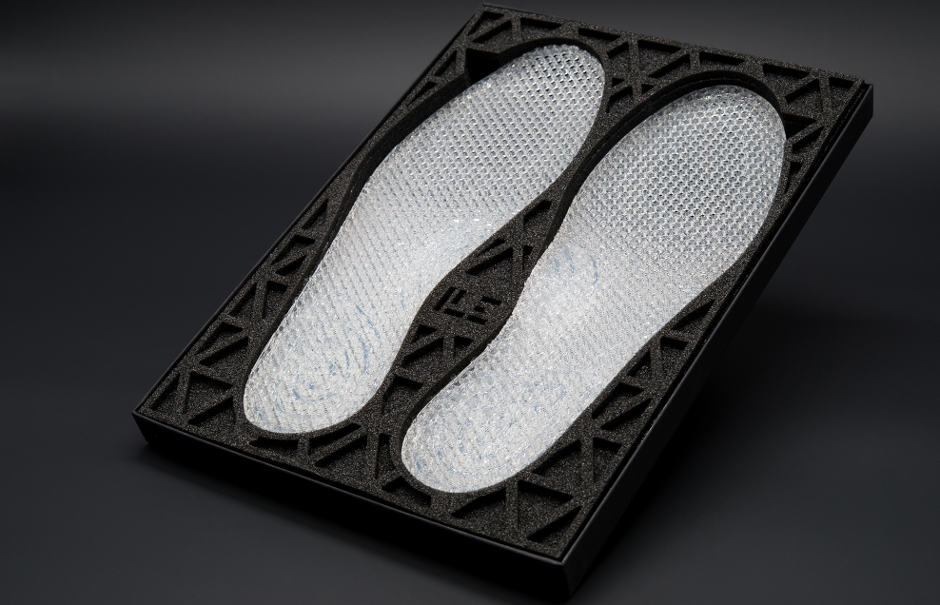

ECCO’s QUANT-U project takes individual data to produce customised silicone midsoles via an in-store additive manufacturing process.

In the space of a few minutes, consumers receive a full digital analysis of their foot structure and the way they move. Shoes are then tailored to their specific requirements in a few hours.

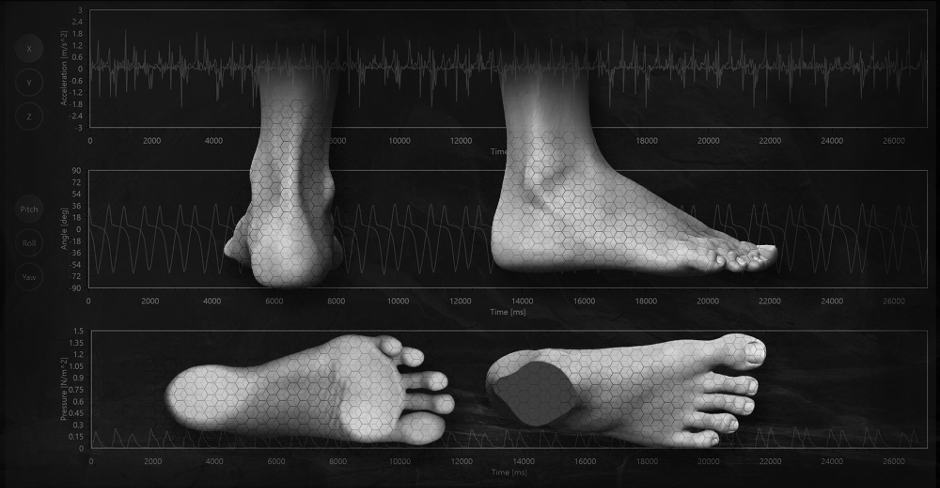

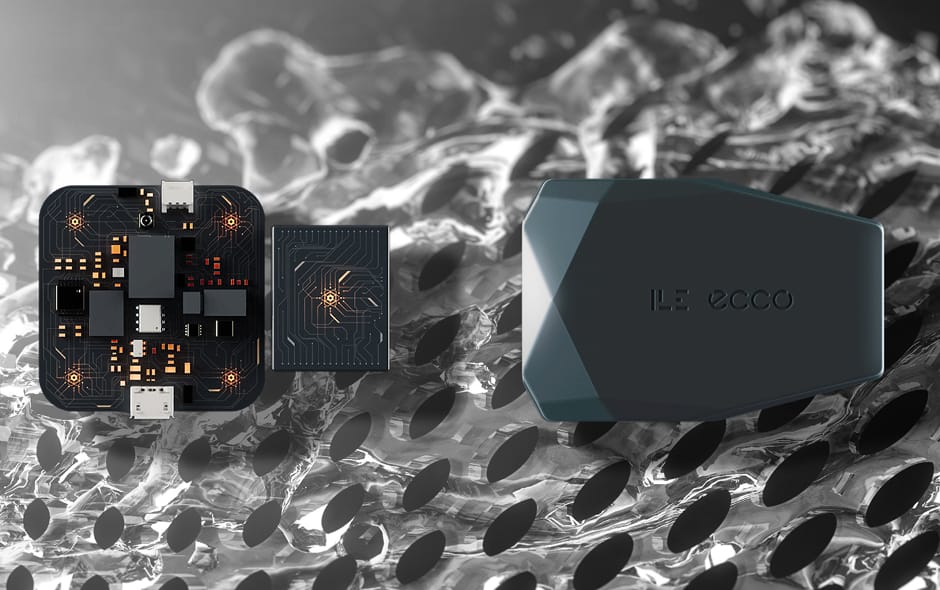

A wearable sensor embedded in the soles of the test shoes collect data using gyroscopes, pressure sensors and accelerometers – as well as recording the temperature and humidity inside each shoe – to create a unique digital footprint.

This data is autonomously translated into geometries for in-store 3D printing of shoes based on each individual’s biomechanical and orthotic parameters.

“The biggest challenge was the fact that the sensors are very close to the ground, hidden inside shoes and covered by a human body – yet they need to send data from both shoes simultaneously to a connected device such as a mobile phone,” said Roberto Basile, a software engineer at CDP. “We needed to maintain reliable communication – using Bluetooth Low Energy – despite the human body acting as an obstacle to the wireless signals. The mechanical system inside the sensor had to be robust enough for people to walk on it, while the battery had to be small and last at least three days without being recharged.”

The first prototype of the wearable sensor was created by CDP and ECCO in under four months. The inbuilt algorithm filters the raw biomechanical data from the sensor into functional information. This data creates the input parameters for a 3D-printed customised midsole for individual customers in approximately two hours.

“Additive manufacturing offers the chance to create bespoke parts in series but this is rarely translated in a consumer product; most likely due to the complexity of the 3D models and a lack of measuring data to begin with,” said Patrizio Carlucci, head of ILE (Innovation Lab ECCO). “To solve this, we focused heavily on the digital capture and interpretation of motion and orthotic data, then made sure this experience would be no more complicated than trying on a shoe in the store and walking for a few minutes. We truly translated more than 50 years of shoe making experience into an algorithm.”

The QUANT-U (‘quantified you’) project will have an initial public release at W-21 Amsterdam – ECCO’s concept shoe store – in April.

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...