This is the claim of a team of researchers at North Carolina State University (NC State) who found the CNT film to possess a combination of thermal, electrical and physical properties that make it a viable candidate for next-generation smart fabrics. The team’s findings are detailed in ACS Applied Energy Materials.

Graphene infused garments regulate body temperature

The researchers are also said to have optimised the thermal and electrical properties of the material, allowing it to retain its desirable properties even when exposed to air for many weeks. According to NC State, these properties were achieved using processes that were relatively simple and did not need excessively high temperatures.

In a statement, Tushar Ghosh, co-corresponding author of the study said: “Many researchers are trying to develop a material that is non-toxic and inexpensive, but at the same time is efficient at heating and cooling.

“Carbon nanotubes, if used appropriately, are safe, and we are using a form that happens to be inexpensive, relatively speaking. So it’s potentially a more affordable thermoelectric material that could be used next to the skin.”

“Right now, the research into clothing that can regulate temperature focuses heavily on integrating rigid materials into fabrics, and commercial wearable thermoelectric devices on the market aren’t flexible either,” said Kony Chatterjee, first author of the study and a Ph.D. student at NC State.

Chatterjee said that to cool the wearer, CNTs have properties that would allow heat to be drawn away from the body when an external source of current is applied.

“Think of it like a film, with cooling properties on one side of it and heating on the other,” Ghosh said.

The researchers measured the material’s ability to conduct electricity, plus its thermal conductivity. They found the material to have relatively low thermal conductivity, so heat would not travel back to the wearer easily after leaving the body in order to cool it. Similarly, if the material were used to warm the wearer, the heat would travel with a current toward the body, and not pass back out to the atmosphere.

The researchers were able to measure the material’s thermal conductivity through a collaboration with the lab of Jun Liu, an assistant professor of mechanical and aerospace engineering at NC State. The researchers used a special experimental design to more accurately measure the material’s thermal conductivity in the direction that the electric current is moving within the material.

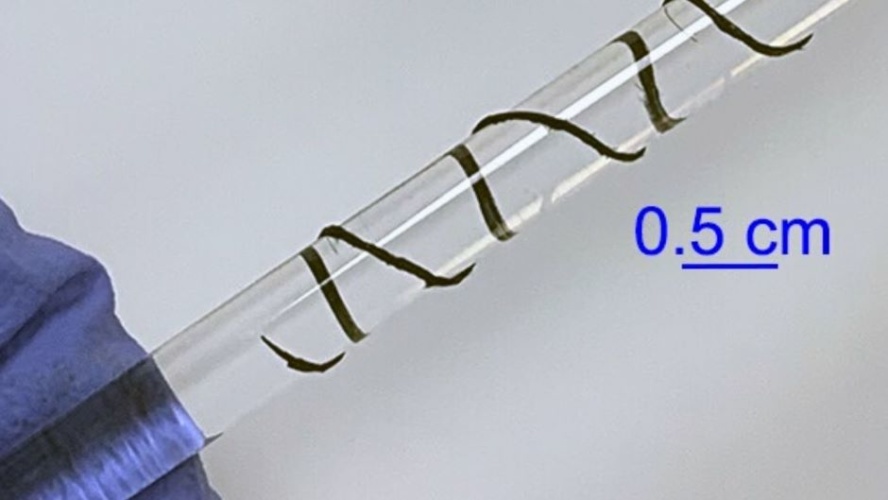

“You have to measure each property in the same direction to give you a reasonable estimate of the material’s capabilities,” said Liu, co-corresponding author of the study. “This was not an easy task; it was very challenging, but we developed a method to measure this, especially for thin flexible films.”

The research team also measured the ability of the material to generate electricity using a difference in temperature between two environments. Researchers said that they could take advantage of this for heating, cooling, or to power small electronics.

Liu said that while these thermoelectric properties were important, it was also key that they found a material that was also flexible, stable in air, and relatively simple to make.

“The point of this paper isn’t that we achieved the best thermoelectric performance,” Liu said. “We achieved something that can be used as a flexible, electronic, soft material that’s easy to fabricate. It’s easy to prepare this material, and easy to achieve these properties.”

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...