It’s perhaps surprising, given the increasingly divisive nature of the Brexit conundrum. But at a time when all we seem hear about is the severing of political ties to Europe, the UK is becoming ever more closely connected to the European mainland via an ambitious series of underwater power cables linking its energy network with the grids of its nearest continental neighbors.

Across Europe, these so-called interconnectors, which enable countries to trade and transfer electricity across borders, are viewed as an increasingly important way of boosting security of supply; stabilising prices; managing fluctuations in supply and demand; and driving the uptake of low-carbon technologies by helping to provide a solution to intermittency issues.

There are already almost 4,000 MW of interconnectors joining the UK to France, the Netherlands, and the Republic of Ireland, and with a pipeline of approximately 12,000MW of projects proposed or under construction by 2025, they form a major element of the UK National Grid’s strategy for the future.

UK / Europe interconnectors

There are already 4,000 MW of operational interconnectors linking the UK to France, the Netherlands, Northern Ireland and the Republic of Ireland, and a pipeline of approximately 12,000MW of projects proposed or under construction by 2025.

- IFA1 – 70km, 2GW link with France. Opened in 1986

- Britned –1GW, 260km link with the Netherlands. Commissioned in 2011

- NEMO – 1 GW link with Belgium (2019) began operating Jan 2019

- IFA2 – 1GW link with France. Due to be commissioned in 2020

- Viking Link - 760km long, 1.4GW link with Denmark. Expected to be up and running in 2023

- East West Interconnector – 500 MW connection between Wales and Ireland. Commissioned in 2012

- Moyle Interconnector - 500MW high-voltage direct current (HVDC) link between Scotland and Northern Ireland. Went into service in 2001.

Earlier this year (2019) the highest capacity link yet, the 1GW NEMO interconnector – which connects the UK with Belgium – was switched on, and work is already underway on a number of other projects including the longest and most ambitious connector to date: the North Sea Link (NSL), a 720km, 1.4GW capacity electricity link between Norway and the UK.

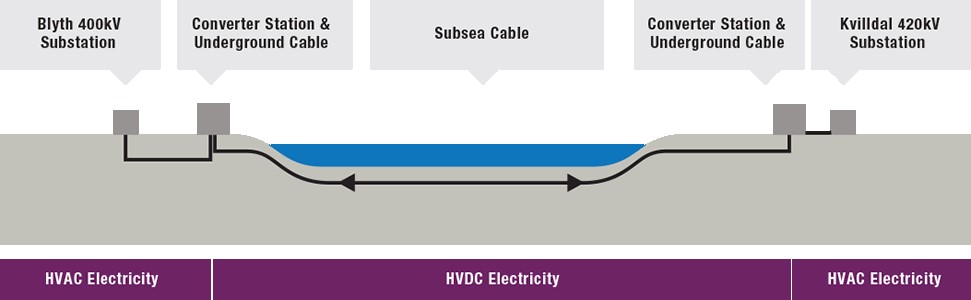

A joint project between the UK’s National Grid and Norwegian grid operator Stattnet, NSL will link Kvilldal in Norway to Blyth in Northumberland via two parallel high voltage direct current (HVDC) subsea cables. Both sites are key strategic locations for energy infrastructure. Blyth, an increasingly important hub for the UK offshore energy sector, is home to the first offshore wind farm in the UK and The National Renewable Energy Centre Catapult research facility, whilst Kvilldal is the site of Norway’s largest hydroelectric power station.

_____________________________________________

Further reading

- ABB wins €300m interconnector contract

- Subsea cable set to improve internet connectivity in Africa

- Nexans wins Denmark-Norway subsea power cable contract

___________________________________________________________________

When it begins operating in 2021, NSL will not only become the longest subsea interconnector in the world but also, according to Project Director, National Grid’s Nigel Williams, one of the only links of its kind to exclusively carry green energy. “Norway is 100 percent hydro and on our side the only time we would trade electricity from the UK to Norway would be when the price is lower here than it is there and that only happens when there’s a surplus of wind, so it’s fair to say North Sea Link is always carrying green electricity.” Williams added that in the early years of operation, thanks to Norway’s abundance of hydro, the direction of travel along the cable is going to be dominated by flows of electricity from Norway to the UK.

"It’s fair to say North Sea Link is always going to be carrying green electricity."

Nigel Williams, project director

In common with other interconnectors, NSL consists of two key components: the cable system and the converter stations at each end which convert electricity from AC (which is used in each country’s transmission system) to DC (which is used for sending the electricity along the subsea cable) and vice-versa.

Construction of the converter stations is already well underway, explained Williams. At Kvilldal all of the civil works are complete, and the team has just begun electrical installation and fit out work whilst electrical work at the UK end is due to start around the end of this year (2019). Both stations are being built by ABB and are based its HVDC Light technology, which has been specially designed to transmit power underground and under water and over long distances.

Arguably the most logistically challenging area of any interconnector project though, is the installation of the cable system itself, and NSL is no exception.

This process began, explained Williams, with a painstaking route planning operation, aimed at ensuring that the cable avoids major seabed obstacles such as oil pipelines. Another consideration is ensuring that the cable doesn’t come into contact with one of the tens of thousands of unexploded first and second world war bombs that are thought to litter the seabed around the UK.

In common with other offshore engineering projects NSL has employed specialist contractors who have used advanced magnetometer technology to scan the seabed for the tell-tale signature of buried metallic objects. So far, said Williams, they’ve not had any problems.

The cable itself is being manufactured and installed by two separate contractors: Prysmian and Nexans. Nexans, which is currently producing the cable at its Halden Plant in Norway, is responsible for the 500km of cabling that will run in the fjord and onshore sections in Norway, whilst Prysmian - which is manufacturing cable for the project at its plant in Milan - is supplying around 950km on the UK and Norwegian North Sea sections of the route.

The use of two contractors is, said Williams, normal for a project of this scale. “Our route is 720km end to end and we’re laying 2 cables so we need 1440 km. If we want one factory to make all that cable we wouldn’t be able to go live in 2021 because of the constraints in the factory.”

Most of the cabling work carried out so far has been on the Prysmian side. Last year, two 130km sections of cable were laid, and three more will be down by the end of the 2019. Prysmian will complete its share of the cabling in 2020 with two further sections. Nexans will begin next year, and complete its cable laying in 2021.

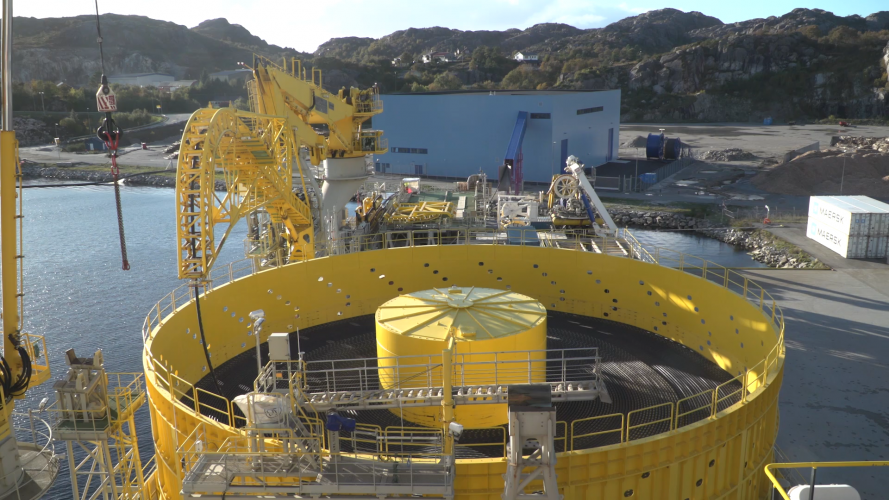

The cable is installed in two phases, explained Williams, beginning with the arrival of the cable laying vessel, which uses a giant turntable and dynamic position systems to painstakingly unwind its payload and lay it on the seabed. In good weather it takes about ten days to lay a whole 130km section, he said.

The next step is to secure and protect the cable on the seabed, and ensure that it’s buried deeply enough to avoid being caught up by trawler nets. Here, explained Williams, specialised ROVs (remotely operated vehicles) is used. Attached to an umbilical that provides power and a visual link to the surface, these are carefully positioned so that they straddle the cable on the seabed. They then move slowly forwards, using high pressure jets of seawater to carve a trench on the seabed, into which the cable drops as they pass by. Williams said that the aim is to bury the cable at least one metre below the seabed.

Whilst the core components and key techniques are the same as those used on other interconnector projects, NSL has, nevertheless, presented a number of unique engineering challenges, said Williams, not least the broad challenge of being the first interconnector project to cross the North Sea, a particularly crowded body of water when it comes to existing energy infrastructure. “The North Sea has never been crossed by big power cable before,” he said, “so we're trailblazing a little bit. And all the crossings in the North sea and dealing with all the different oil companies is a challenge.”

“The North Sea has never been crossed by big power cable before, so we're trailblazing a little bit. And all the crossings in the North sea and dealing with all the different oil companies is a challenge.”

It also presents a significant geological challenge in the form of the Norwegian trench, a 700 metre deep ravine in the sea floor off the south coast of Norway that the cable has to cross. “We have to pick a cable route that affixes the cable to the floor, we don’t want any suspended cable sections,” he said.

But perhaps the biggest challenge for the project, and one which sets it apart from initiatives linking the UK with low-lying nations like the Netherlands, is the mountainous nature of Norway, and the deep, narrow environment of the fjords.In order to reach the converter station at Kvilldal, the cable has to pass through Hylsfjorden, a 20km long Fjord in Western Norway. From here, it goes through a specially excavated 2.3 km tunnel that takes it up into the mountains to Lake Suldalsvatnet, the sixth deepest lake in Norway (376 metres deep) . It then runs across the bottom of the lake to the converter station at Kvilldal.

Rune Stoten, Nexans’ project manager for NSL explained that this is one of the most unusual and challenging parts of the project and, has required the construction of a purpose built barge that can be assembled in situ in the lake. “It’s specially designed for this project and equipped with laying equipment so you can spool the cable from the turntable,” he said. “It also has a separate ROV that can monitor the cable during laying” Stoten said that this operation will take place in the summer of 2020.

When NSL opens for business in 2021, the relationships that underpin the trading of electricity in Europe could look very different. Norway, of course, isn’t a member of the EU, but as part of the European Economic Area, enjoys many of the same benefits, and there are growing concerns that should the UK leave the bloc without a deal, cross border trade in electricity could also be affected.

But whilst acknowledging that Brexit could have an impact Williams prefers to take the long view. “All I would say is that we’re putting a cable system in for the next fifty years and Brexit is one point in time. Whatever happens, life will go on. The decarbonisation challenge will still be there; Norwegian hydropower will be there; our excess wind will still be there and the long term need for this is there.”

In the meantime, he praises Norway for taking a more joined up view of the future of European energy. “ It’d be easy for them to say “I’m all right Jack” our system is dominated by hydro, we’re very clean and we’ll keep it to ourselves. But….they take a view that if they can help some of their near neighbors out with some hydro and that can offset some burning of fossil fuels then it’s a win win-win for everyone – they get to sell more product and the help to deliver a greener world.”

"The power systems of the future will require us to be strongly linked to near neighbours. Cooperating in this way is what will make the world go round."

More generally, whatever the broader political climate, Williams sees interconnectors, and a more joined up approach to power sharing, as key to the future of the European energy. “The power systems of the future will require us to be strongly linked to near neighbours,” he said. “In continental Europe there’s an infinite source of help. If we have a rapid power deficit for some reason, where else to get a fast injection from than Europe or Norway? Using our neighbours and cooperating in this way is what will make the world go round.”

All images courtesy of National Grid

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...