Meet the panel

Jennifer Milne, Product Marketing Lead at Formlabs

Dave Veisz, VP of Engineering, MakerBot

Bryan Austin, Director of Additive Manufacturing Sales, Renishaw

What trends / customer requirements are driving developments in your product area?

JM: One of the major trends driving additive manufacturing is material science. The materials that are used in the 3D printing process, when coupled with novel designs only possible with 3D printing, enable customers to develop products that perform better than those created through traditional means of manufacturing. Material science is impacting every application 3D printing can be used for - from healthcare to engineering. In the healthcare use case in particular, the customer need for biocompatible materials is driving the industry to create plastics that are ISO 13485 certified.

JM: One of the major trends driving additive manufacturing is material science. The materials that are used in the 3D printing process, when coupled with novel designs only possible with 3D printing, enable customers to develop products that perform better than those created through traditional means of manufacturing. Material science is impacting every application 3D printing can be used for - from healthcare to engineering. In the healthcare use case in particular, the customer need for biocompatible materials is driving the industry to create plastics that are ISO 13485 certified.

DV: Our products are developed with customers’ needs in mind. We work with companies that operate across different industries, including automotive, aerospace, consumer goods, and robotics, so the demand for engineering-grade materials is high. As a result, we have been developing advanced materials that address their needs, such as Nylon Carbon Fiber, PC-ABS and PC-ABS FR. We have also partnered with leading global materials companies, including BASF, Kimya, Mitsubishi Chemical, Polymaker, Lehvoss, and Jabil, to launch MakerBot LABS for METHOD, an open materials platform that lets our users print a variety of specialty materials, future-proofing their investment in a 3D printing platform.

BA: In many market-sectors additive manufacturing (AM) has progressed beyond being simply an interesting technology for researchers, to becoming embedded into mainstream manufacturing. As such the drivers for the use of the technology are the same as for any other production process, which is cost per part and quality. This means that there is a growing requirement for sensibly priced multi-laser systems that can guarantee good quality parts on a consistent basis and high productivity.

Give one or two examples of how your products are helping customers meet the challenges that they are facing?

JM: Formlabs were instrumental in helping University of South Florida Health and Northwell Health, the largest health provider in New York State, develop a 3D printed nasal swab to be used to test for COVID-19. Formlabs 3D printers enabled these hospital systems to rapidly prototype the design and go on to produce them in large volume. Also, Formlabs’ 3D printers enabled Ashley Furniture to iterate on the shop floor in real time. Ashley Furniture is doing 10% more business and has eliminated the need for outsourced manufacturing, bringing lead times down from 3-4 weeks to 15.5 hours and reducing costs from $10 to $5.90 per part.

DV: All Axis Robotics, a machine shop and leader in turnkey robotics and automation solutions for other machine shops, uses the MakerBot METHOD X to produce custom tooling parts - significantly reducing lead times for its bespoke end-effector designs. This ability to create custom solutions for customers has helped All Axis Robotics gain a competitive advantage against competitors. A couple of examples of end-effectors include a custom part sander manufactured in MakerBot ABS material and a dual gripper mount produced in Kimya ABS Carbon.

DV: All Axis Robotics, a machine shop and leader in turnkey robotics and automation solutions for other machine shops, uses the MakerBot METHOD X to produce custom tooling parts - significantly reducing lead times for its bespoke end-effector designs. This ability to create custom solutions for customers has helped All Axis Robotics gain a competitive advantage against competitors. A couple of examples of end-effectors include a custom part sander manufactured in MakerBot ABS material and a dual gripper mount produced in Kimya ABS Carbon.

BA: Sandvik has worked with Renishaw AM systems since 2018 at its Additive Manufacturing Centre in Sandviken, Sweden. During this time, the two companies have worked together to develop process parameters for a range of Sandvik metal powders, including stainless and maraging steels, and the latest Osprey nickel-based superalloys. Sandvik has recently inaugurated a state-of-the-art titanium atomiser and powder processing facility and will now turn its focus to qualifying these alloys for industrial and medical applications.

BAE Systems began research into additive manufacturing techniques more than two decades ago and are currently using the technology to make production standard components for the Typhoon fighter aircraft. It is also applied in the rapid prototyping of new technology concepts as part of a drive to deliver Tempest - a capable, affordable and exportable next generation future combat air system.

What is the key product for you currently and how is it being applied?

JM: Form 3B is Formlabs’ newest 3D printer and was created for the dental industry. This one printer allows for a growing list of over 10+ dental applications from digital dentures to temporary crowns and bridges. Users can switch between a library of resins with a no-hassle cartridge system. Formlabs is providing a localised approach to the production of dental products like dentures. While scans are made at your dentist’s office, it’s a nearby dental lab that makes the part – and that lab can serve many dentists. By bringing 3D printing into these labs, technicians can produce multiple products at a time, significantly shortening lead times.

DV: We recently launched new METHOD and METHOD X Carbon Fiber Editions, which allow users to print carbon fibre reinforced nylon that is optimised for high strength and heat resistance. MakerBot Nylon Carbon Fiber is an ideal lightweight alternative to metal for structural applications. METHOD Carbon Fiber enables customers to print various parts, such as vehicular brackets and inspection gauges, manufacturing tools such as robotic end-effectors, and under-hood applications.

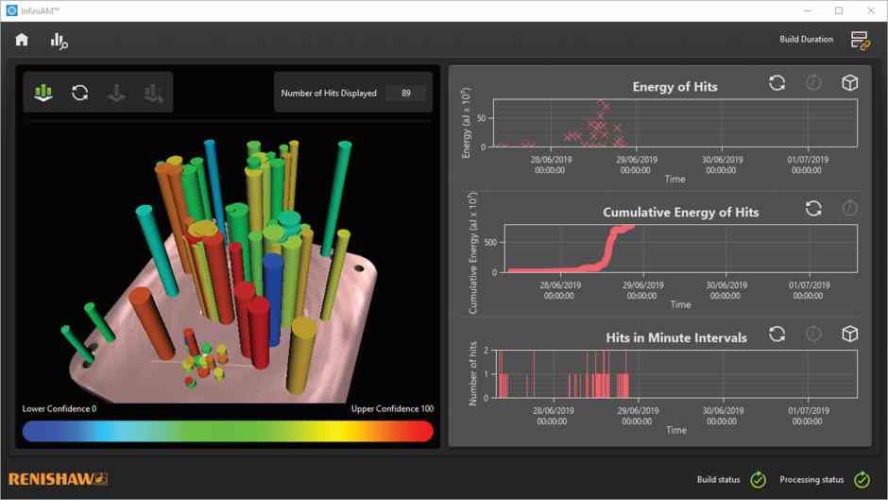

BA: The Renishaw RenAM 500Q multi laser system has been designed to deliver high productivity whilst maintaining very high-quality metal parts. When applied to the right application the system delivers extremely competitive cost per part and can be validated to operate in regulated market sectors such as medical and aerospace. The Ren AM 500Q is supplied with an on-board sieving system and can be configured as a four or single laser system.

BA: The Renishaw RenAM 500Q multi laser system has been designed to deliver high productivity whilst maintaining very high-quality metal parts. When applied to the right application the system delivers extremely competitive cost per part and can be validated to operate in regulated market sectors such as medical and aerospace. The Ren AM 500Q is supplied with an on-board sieving system and can be configured as a four or single laser system.

What products / technologies do you see changing your sector in the future?

JM: Generative design, which enables engineers to create thousands of design options by defining their design problem - inputting parameters such as fixed points and bounding constraints, applied forces and loading considerations, a factor of safety, and what material and manufacturing options are available to them. The program then provides a range of possible solutions to choose from or iterate on. When coupled with 3D printing it is possible to rapidly generate and test novel, lightweight design solutions leading to prototypes and products that perform better than similar products created with traditional means of design and manufacturing.

DV: New capabilities in FDM 3D printing are changing the traditional rules of manufacturing. Industrial features that have historically only been available on costly industrial 3D printers are now more accessible to more manufacturers and machine shops. In addition, advances in 3D printing materials development are enabling 3D printing to evolve from simple prototyping applications to mass customization of production end use parts.

BA: As the requirements for increased speed of throughput and reduced cost per part become ever stronger, the size of machine and number of lasers will become even more important in meeting these manufacturing demands. Larger machines should enable more components or bigger parts to be built and advances in automation will improve throughput. Validating that each machine will produce repeatable, consistent parts is becoming increasingly important for our customers and at Renishaw we are well placed to offer complete process solutions that draw on our historic strengths in measurement and process control.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.