Researchers at Rensselaer Polytechnic Institute have developed a simple new technique for identifying and repairing small, potentially dangerous cracks in high-performance aircraft wings and many other structures made from polymer composites.

By infusing a polymer with electrically conductive carbon nanotubes, and then monitoring the structure’s electrical resistance, the researchers have been able to pinpoint the location and length of a stress-induced crack in a composite structure. Once a crack is located, engineers can then send a short electrical charge to the area in order to heat up the carbon nanotubes and in turn melt an embedded healing agent that will flow into and seal the crack with a 70 percent recovery in strength.

Real-time detection and repair of fatigue-induced damage will greatly enhance the performance, reliability, and safety of structural components in a variety of engineering systems, according to Nikhil A. Koratkar, an associate prof in Rensselaer’s Department of Mechanical, Aerospace and Nuclear Engineering.

The majority of failures in any engineered structure are generally due to fatigue-induced microcracks that spread to dangerous proportions and eventually jeopardise the structure’s integrity, Koratkar said. His research is looking to solve this problem with an elegant solution that allows for real-time diagnostics and no additional or expensive equipment.

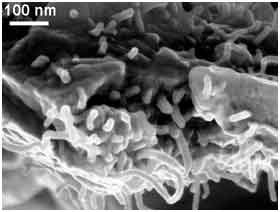

Koratkar’s team made a structure from common epoxy, the kind used to make everything from the lightweight frames of fighter jet wings to countless devices and components used in manufacturing and industry, but added enough multi-walled carbon nanotubes to comprise 1 percent of the structure’s total weight. The team mechanically mixed the liquid epoxy to ensure the carbon nanotubes were properly dispersed throughout the structure as it dried in a mould.

The researchers also introduced into the structure a series of wires in the form of a grid, which can be used to measure electrical resistance and also apply control voltages to the structure.

By sending a small amount of electricity through the carbon nanotubes, the research team was able to measure the electrical resistance between any two points on the wire grid. They then created a tiny crack in the structure, and measured the electrical resistance between the two nearest grid points. Because the electrical current now had to travel around the crack to get from one point to another, the electrical resistance of the circuit increased. The longer the crack grew, the higher the electrical resistance between the two points became.

Koratkar is confident this method will be just as effective with much larger structures. Since the nanotubes are ubiquitous through the structure, this technique can be used to monitor any portion of the structure by performing simple resistance measurements without the need to mount external sensors or sophisticated electronics.

'The beauty of this method is that the carbon nanotubes are everywhere. The sensors are actually an integral part of the structure, which allows you to monitor any part of the structure,' Koratkar said.

Koratkar said the new crack detection method should eventually be more cost effective and more convenient than ultrasonic sensors commonly used today. His sensor system can also be used in real time as a device or component is in use, whereas the sonic sensors are external units that require a great deal of time to scan the entire surface area of a stationary structure.

Plus, Koratkar’s system features a built-in repair kit.

When a crack is detected, Koratkar can increase the voltage going through the carbon nanotubes at a particular point in the grid. This extra voltage creates heat, which in turn melts a commercially available healing agent that was mixed into the epoxy. The melted healing agent flows into the crack and cools down, effectively curing the crack. Koratkar shows that these mended structures are about 70 percent as strong as the original, uncracked structure – strong enough to prevent a complete, or catastrophic, structural failure. This method is an effective way to combat both microcracks, as well as a less-common form of structural damage called delamination.

'What’s novel about this application is that we’re using carbon nanotubes not just to detect the crack, but also to heal the crack,' he said. 'We use the nanotubes to create localised heat, which melts the healing agent, and that’s what cures the crack.'

The ongoing research project is funded in part by the National Science Foundation and the US Army.

Prof Nikhil Koratkar has developed a new method to use carbon nanotubes for both detecting and repairing tiny cracks in nearly any polymer structure

JLR teams with Allye Energy on portable battery storage

This illustrates the lengths required to operate electric vehicles in some circumstances. It is just as well few electric Range Rovers will go off...