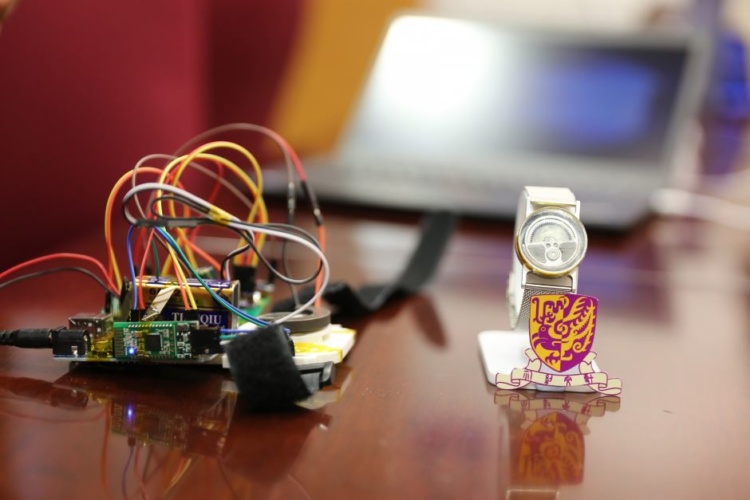

Led by Professor Wei-Hsin Liao, chairman of the Department of Mechanical and Automation Engineering (MAE) at CUHK, the team has proposed a ‘highly compact’ embedded generator equipped with a motion capture unit, a magnetic frequency-up converter and a power generation unit, complete with coaxial topology. Although the total volume of the harvester is 5cm3, researchers claim it can achieve 1.74mW power output.

Knee-powered energy-harvester keeps devices running

The energy harvesting system has been designed to easily embed into smart watches and other wrist-worn wearables to provide a sustainable power supply. Functions such as health monitoring, contactless payment, entertainment and living assistance are making smart watches and wearables more popular but limited battery life remains an issue.

Energy harvesters have been used to power up traditional watches in which mechanical gears are equipped to increase the frequency of human motion and convert mechanical energy to electricity, but these designs require precision manufacture, and the mechanical friction caused by gears leads to significant energy loss with devices occasionally suffering mechanical failure.

In a statement, research group member Dr Mingjing Cai said: “The low frequency of human motion results in relatively low energy conversion efficiency. We applied a magnetic frequency-up converter to increase the frequency of human motion, which helps the energy harvester to efficiently convert the human motion into electrical energy. With the magnetic frequency-up converter, the output power of the device can be significantly enhanced, achieving ten times that of [existing] devices.”

The mechanical frequency-up converter uses magnetic force for transmission, avoiding the energy loss caused by mechanical friction and potentially protecting the device from impact. Another advantage of the magnetic frequency-up converter is its simple structure and low cost, which could help to commercialise the device in future.

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...