Researchers at Nottingham University have developed EcoVent, a novel window ventilation/heat recovery system aiming to minimise the impact of COVID-19 dispersion in buildings.

The research team is led by Professor Saffa Riffat, Fellow of the European Academy of Sciences and President of the World Society of Sustainable Technologies.

In order to minimise the risk of high virus concentration airflow, ventilation rates need to be maximised in buildings.

MORE ON THE ENGINEERING RESPONSE TO COVID-19 HERE

However, ventilation rates in many naturally ventilated buildings (such as care homes, restaurants and schools) are inadequate. In general, traditional windows can only be used within the short summer months due and can present other issues, such as outdoor noise and pollutants. Closing windows in winter does not allow virus dispersion and can result in poor indoor air quality, dampness and damage to building fabric.

Meanwhile, conventional centralised mechanical ventilation heat recovery systems (MVHR) can be noisy, bulky, require ducting and be costly in installation, therefore are not widely implemented.

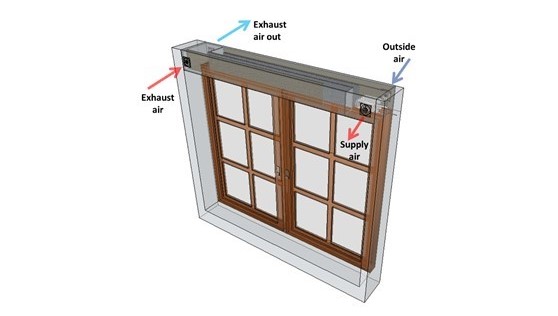

According to researchers, the EcoVent system can be retrofitted into window frames and uses displacement ventilation with 100 per cent fresh air supplied to buildings. The system uses either a heat pipe/heat exchanger to recover sensible heat loss or an enthalpy heat exchanger unit to capture both sensible and latent heat losses from outgoing warm air, using this heat to warm the incoming air. The heat pipe/heat exchanger allows the recovery of about 60 per cent of waste heat while the enthalpy heat exchanger allows the recovery of around 85 per cent of heat loss.

Membranes coated with an absorbent material (such as sodium chloride and calcium chloride) are used by the enthalpy heat exchangers, and the EcoVent is fitted with ‘highly efficient’ bio-aerogel air filters for removal of particular pollutants such as PM 2.5 when outside air enters the building. The system could also effectively capture airborne contaminants and kill viruses entering the building, researchers claim.

The team have described the system as ‘inexpensive, compact and much easier to install compared to conventional MVHR systems’. In addition, they have suggested that the system could be used in bathrooms, showers and kitchens to minimise heat loss/draught due to ventilation for both existing and new buildings.

EcoVent’s system is has been evaluated using a so-called Hot Box laboratory at the Nottingham University which allows simulation of indoor and outdoor environments. The Hot Box allows evaluation of a full size EcoVent and is fitted with measuring and data-logging instrumentations to allow continuous monitoring, the team explained.

Nottingham University has worked with industry partners EPS Ltd and PAK Engineering on the development of the EcoVent system, which has been funded by Innovate UK. Outdoor facilities at PAK Engineering have also been used for the testing of the system.

“We are currently applying for further funding involving manufacturers of window and construction companies in order to demonstrate the EcoVent technology in real buildings,” said Prof. Riffat. “Our aim is to turn the EcoVent technology into a marketable product.”

Swiss geoengineering start-up targets methane removal

No mention whatsoever about the effect of increased methane levels/iron chloride in the ocean on the pH and chemical properties of the ocean - are we...