FASTBLADE is the world’s first composite and materials test facility with regenerative fatigue loading currently being developed between the University of Edinburgh and Babcock International to conduct large-scale, accelerated testing. FASTBLADE test facility will be based at Babcock’s Rosyth location.

Neil Young, a technology director at Babcock, and Professor Conchúr Ó Brádaigh, head of engineering at the University of Edinburgh, explain what it’s all about.

Q: Who came up with the initiative of FASTBLADE and why?

COB: FASTBLADE is a concept created by the university with Babcock as the principal engineering designer. I’ve been working for the past 32 years in composite materials research, both within industry and at the university, and it became apparent that there was a clear need for a concept that could deliver full scale fatigue testing of industrial blades, such as tidal. Blades are the prime movers of tidal energy devices and that’s what we’ll be testing first.

Q: What does the partnership with Babcock offer?

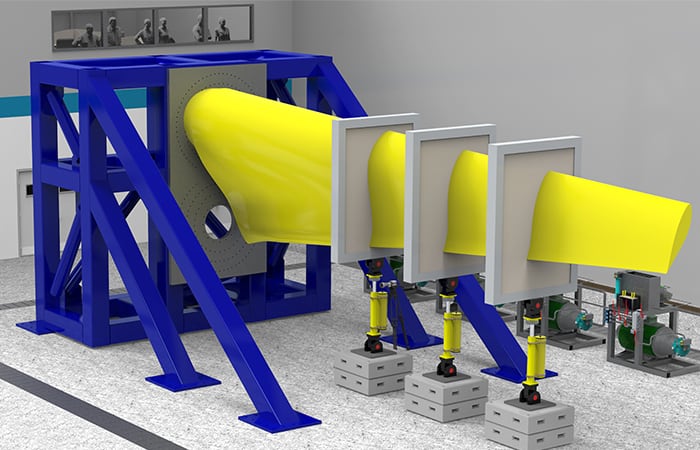

NY: FASTBLADE is part of Babcock’s wider plans around innovation, technology and composite research. The University approached us because they were looking for specialist facilities and engineering design expertise to help get the project from research application to reality. At Rosyth, we have both these key requirements, which aren’t available anywhere else in a single location. As principal designers of the facility we have optimised the design of the reaction frame to which the composite structure is mounted. This includes upgrading the foundation design in the building to accommodate the additional loads imposed by the fatigue testing.

Q: What structures will be tested at FASTBLADE and how will it benefit companies using the facility?

COB: Initially we’ll be testing tidal blades. People think of tidal turbines like wind turbines, but because of the density of the water, which is 800 times greater than air, and the turbulence it creates, it has proved a real engineering challenge to the industry for decades. Tidal blades tend to be shorter and stiffer, more like an aircraft wing box than a wind turbine. As well has being able to fatigue test these blades in a laboratory we are also using a new generation of highly efficient digital displacement hydraulics with regenerative pumping. This use of hydraulic technology will enable structures to be tested significantly faster and using less energy compared with existing technologies. The fact that we have created a system that will recover energy between load cycles, thus reducing the cost of testing for OEMs, is a real game-changer.

NY: For Babcock, this really underpins the existing work we already do in through-life engineering. To be able to gather crucial data in the testing-cycles of composites and materials, such as the next generation of glass and carbon-reinforced plastics, will really help us understand how we can better support the critical and complex assets we manage.

And it won’t just be the marine sector. FASTBLADE will speed the development of materials and structures for a variety of industries, including those in marine, transport, nuclear and aerospace sectors. We have some of our best engineering minds working on this project, along with some of the best academic minds at the University.

COB: FASTBLADE will be able to test structures in a fraction of the time originally needed for this type of fatigue testing. This will allow us to validate the 20-year life design requirement before companies incur significant costs in manufacturing. In conventional hydraulic systems any excess energy would be lost, not recovered. That creates an added cost for companies. The data from our testing will allow us to really drive innovation in all the areas we’ll be testing.

Q: How is FASTBLADE supporting future skills in the technology and data space – will it spark new opportunities for future talent?

NY: For Babcock, securing the right engineering talent isn’t just an aspiration, it’s very much part of our future success as a business and where we can, we will develop our home-grown talent to undertake senior roles. That’s why we have just promoted one of our graduates to Innovation Manager at our Rosyth facility.

COB: It’s our vision to develop learning spaces at the site as we know that the foundation of our future knowledge base will come out of understanding the data we collect. Having the right skills in place to collect and process this data is imperative and helps fulfil the University’s commitments as part of the Edinburgh and South East Scotland City Region Deal, which includes targets to help improve digital skills across the whole of the region. This work will create opportunities for apprentices, graduates, postgraduates and people within businesses. We are working with Babcock to ensure we have that foundation of skills available. The University is also offering a new TRAIN@ED fellowship opportunity for data driven structural testing at FASTBLADE.

NY: This work has also led to us creating a new PhD at the University of Edinburgh in the asset management of composites in the marine environment, which is jointly funded by Babcock and the National Manufacturing Institute for Scotland.

Interested in data research? FASTBLADE has research posts available. For more information visit https://www.ed.ac.uk/human-resources/jobs/train-ed or email jeff.steynor@ed.ac.uk

Babcock is the partner of The Engineer’s 2019 Data Week

MORE ON MATERIALS AND ENERGY & ENVIRONMENT

April 1886: the Brunkebergs tunnel

First ever example of a ground source heat pump?