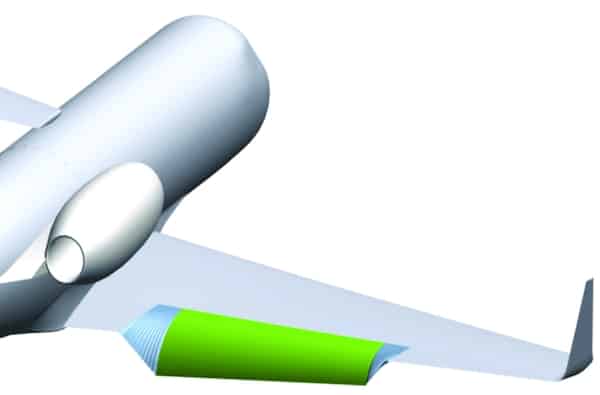

Earlier in 2014, researchers replaced an airplane’s conventional aluminium flaps with advanced, shape-changing assemblies that are said to form seamless bendable and twistable surfaces.

Flight-testing will determine whether flexible trailing-edge wing flaps are a viable approach to improve aerodynamic efficiency and reduce noise generated during take-offs and landings.

The Adaptive Compliant Trailing Edge (ACTE) project is a joint effort between NASA and the US Air Force Research Laboratory (AFRL), using flaps designed and built by FlexSys, a company based in Ann Arbor, Michigan.

With AFRL funding the project through the Air Force’s Small Business Innovative Research program, FlexSys developed a variable geometry airfoil system called FlexFoil that can be retrofitted to existing airplane wings or integrated into brand new airframes.

Using conventional materials and actuators, FlexFoil - with no moving parts in the shape-adapting mechanism - is being applied to demonstrate camber changes (-9 to +40 degrees), span-wise twist and high response rates (50 degrees/sec), along with a control surface that is strong and stiff enough to support over 10,000lbs of air loads.

According to NASA FlexFoil’s inventor, FlexSys founder and CEO Sridhar Kota hopes July’s tests with the modified Gulfstream III will confirm the design’s flight worthiness and open doors to future applications and commercialisation. ACTE is being flown at NASA’s Armstrong Flight Research Center in Edwards, California.

The experimental control surfaces were locked at a specified setting during the initial ACTE flight. Different flap settings will be employed on subsequent flights to collect a variety of data demonstrating the capability of the flexible wings to withstand a real flight environment.

‘We have progressed from an innovative idea and matured the concept through multiple designs and wind tunnel tests, to a final demonstration that should prove to the aerospace industry that this technology is ready to dramatically improve aircraft efficiency,’ AFRL program manager Pete Flick said in a statement.

ACTE technology is expected to have far-reaching effects on future aviation as advanced lightweight materials will reduce wing structural weight and give engineers the ability to aerodynamically tailor the wings to promote improved fuel economy and more efficient operations.

‘The first flight went as planned - we validated many key elements of the experimental trailing edges,’ said Thomas Rigney, ACTE project manager at Armstrong. ‘We expect this technology to make future aircraft lighter, more efficient, and quieter. It also has the potential to save hundreds of millions of dollars annually in fuel costs.’

The flight test forms one of the NASA Environmentally Responsible Aviation (ERA) Project’s eight large-scale integrated technology demonstrations to show design improvements in drag, weight, noise, emission and fuel reductions.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...