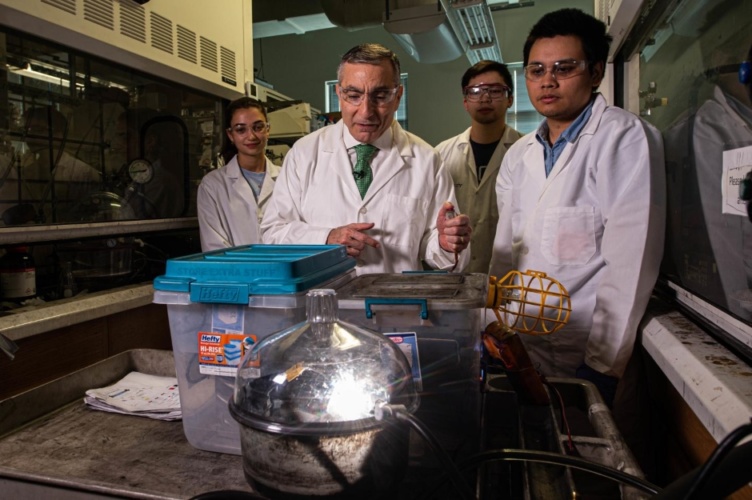

The advance from the Rice University lab of James Tour can reportedly convert a ton of coal, food waste or plastic into graphene for a fraction of the cost used by other bulk graphene-producing methods.

"This is a big deal," Tour said in a statement. "The world throws out 30 per cent to 40 per cent of all food, because it goes bad, and plastic waste is of worldwide concern. We've already proven that any solid carbon-based matter, including mixed plastic waste and rubber tyres, can be turned into graphene." The research is published in Nature.

Texas team turns graphene into bacteria-killing filter

Lasing technique adds graphene to multiple substrates

"With the present commercial price of graphene being $67,000 to $200,000 per ton, the prospects for this process look superb," he said, adding that 0.1 per cent of flash graphene in the cement used to bind concrete could lessen its environmental impact by a third.

"By strengthening concrete with graphene, we could use less concrete for building, and it would cost less to manufacture and less to transport," he said. "Essentially, we're trapping greenhouse gases like carbon dioxide and methane that waste food would have emitted in landfills. We are converting those carbons into graphene and adding that graphene to concrete, thereby lowering the amount of carbon dioxide generated in concrete manufacture. It's a win-win environmental scenario using graphene."

"Turning trash to treasure is key to the circular economy," said co-corresponding author Rouzbeh Shahsavari. "Here, graphene acts both as a 2D template and a reinforcing agent that controls cement hydration and subsequent strength development."

Flash Joule heating for bulk graphene, developed in the Tour lab by Rice graduate student and lead author Duy Luong, is claimed to improve upon techniques like exfoliation from graphite and chemical vapour deposition on a metal foil that require much more effort and cost to produce small quantities of graphene.

The process also produces turbostratic graphene, with misaligned layers that are easy to separate. "A-B stacked graphene from other processes, like exfoliation of graphite, is very hard to pull apart," Tour said. "The layers adhere strongly together.

Turbostratic graphene is easier to work with as the layers come apart in solution or upon blending in composites.

"That's important, because now we can get each of these single-atomic layers to interact with a host composite," he said.

The flash process happens in a custom-designed reactor that heats material quickly and emits all noncarbon elements as gas. "When this process is industrialised, elements like oxygen and nitrogen that exit the flash reactor can all be trapped as small molecules because they have value," Tour said.

He said the flash process produces very little excess heat, channelling almost all of its energy into the target. "You can put your finger right on the container a few seconds afterwards," Tour said. "And keep in mind this is almost three times hotter than the chemical vapour deposition furnaces we formerly used to make graphene, but in the flash process the heat is concentrated in the carbon material and none in a surrounding reactor.

Tour hopes to produce a kilogram a day of flash graphene within two years.

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.