The solar cells, developed by a team from North Carolina State University and the Chinese Academy of Sciences, can be manufactured at room temperature, which has implications for large-scale commercial production.

Plastic solar cells - or organic photovoltaics - are lightweight, flexible, transparent and inexpensive to manufacture, making them useful in multiple applications.

However, the halogen-containing solvents used in their manufacture present obstacles to large-scale commercialisation. These solvents ensure that the solar cell’s morphology maximises its energy efficiency but they are deemed environmentally hazardous. Additionally, the use of these chemicals requires a controlled environment, which adds to production costs.

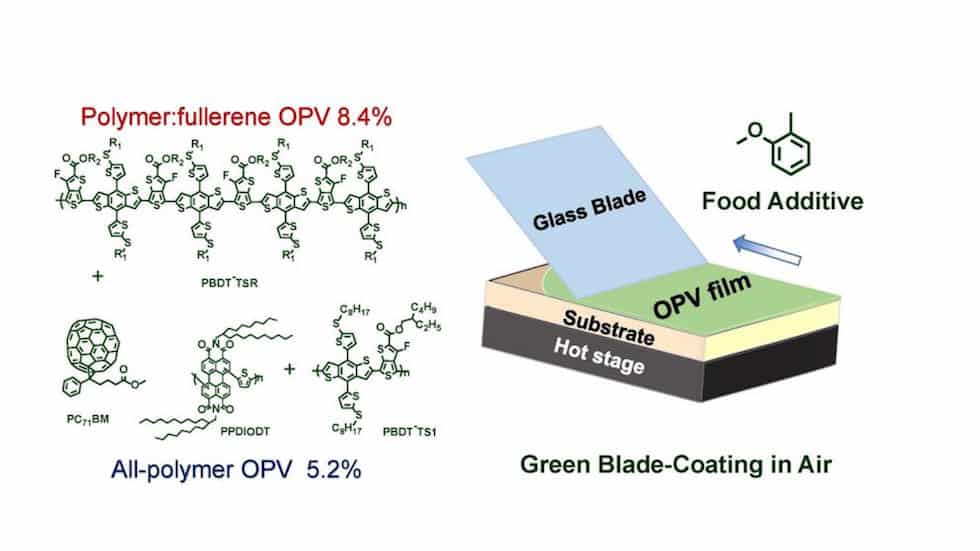

Long Ye, a postdoctoral research scholar in physics at NC State and lead author of a paper describing the work, wanted to find out if non-toxic solvents could provide equally efficient morphology in the manufacturing process. Ye and his colleagues developed a proof of concept semi-printed plastic solar cell that utilised o-methylanisole (o-MA) as the solvent. O-MA is a commonly used flavouring agent in foods, and is non-toxic to humans.

The researchers used soft X-ray techniques to study the morphology of their solar cell and found that the o-MA based solar cell had similar morphology, crystalline features and device performance to those produced by halogenated solvents.

According to NC State, the solar cell’s overall efficiency rating was around 8.4 per cent. Furthermore, their cell could be produced via blade coating at ambient, or room temperature. Blade coating is a process that uses a glass blade to spread a thin layer of the photovoltaic film onto either a rigid or flexible substrate, and the process is compatible with large-scale commercial manufacturing.

“Two of the key requirements for mass producing these solar cells are that the cells can be produced in the open air environment and that the process doesn’t pose health or environmental hazards,” Ye said in a statement. “Hopefully this work can help pave the way for printing solar cells in ambient air.”

The work appears in Chemistry of Materials.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...