The two companies have announced that Forgemasters is to make a trial reactor vessel head for NuScale’s SMR design by the end of 2017, as part of a £4million project funded by Innovate UK.

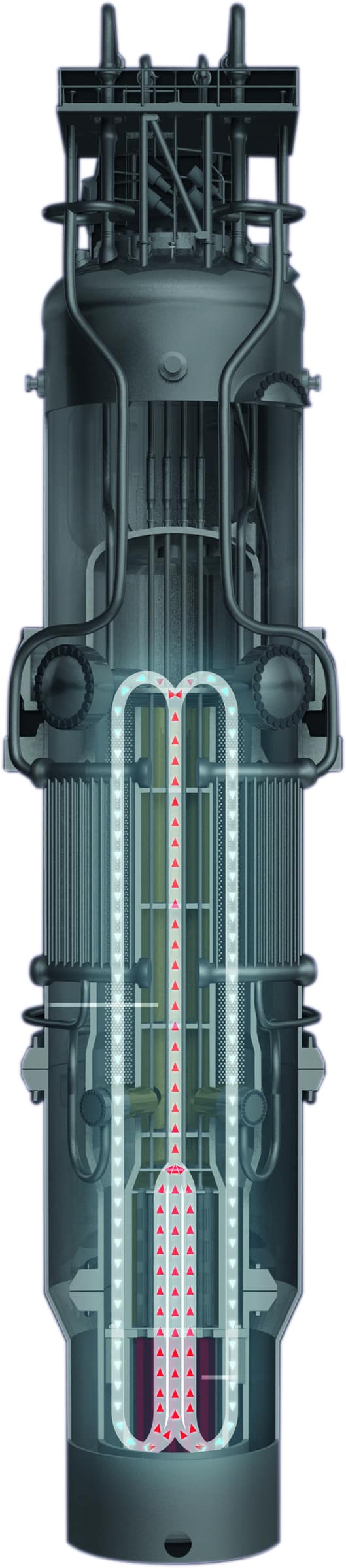

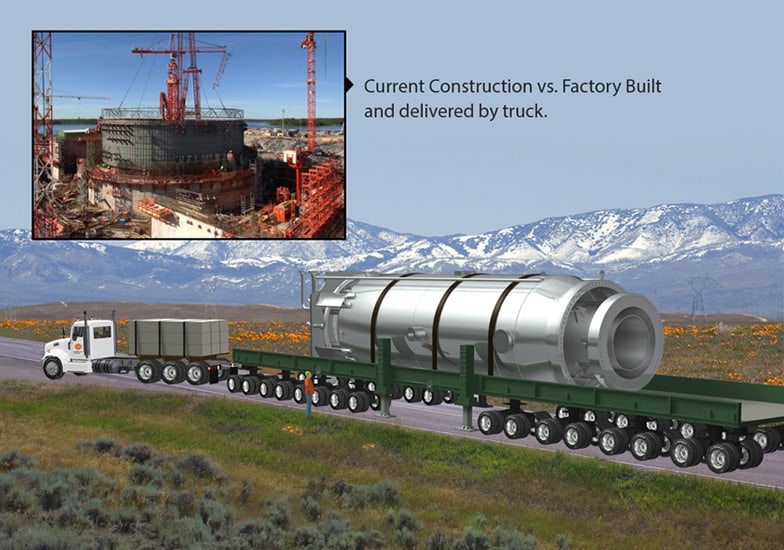

NuScale, part of the giant engineering construction company Fluor, announced its intention to introduce SMR technology into the UK last year. Its technology is based around 50MW reactors (around 5 per cent of the generating capacity of a typical civil reactor) that are intended to be deployed singly or in clusters of up to 12 units. The advantage of this technology is that the reactors are designed to be made on production lines in factories, more cheaply and efficiently than the huge facilities required for conventional reactors.

The reactor head component is a forging about 2.75m in diameter and weighing around 9.5tonnes. None of the NuScale SMR reactors have yet been made, although the company says that it is pursuing the development of a first plant in Idaho; and NuScale is working closely with Forgemasters on the geometries that the reactor head, which houses the system that operate the control rods that moderate the nuclear reaction and the outlets for the steam generators, will require.

Forgemasters has expertise in techniques such as near-net forging, where the approximate shape of a complex component is made by shaping it over a die before it is machined to its precise shape. This is in contrast to the way that conventional reactor heads are made, where the steam generator outlet pipes are typically forged separately from the main domed ‘lid’ of the reactor and attached using highly specialised welding techniques to ensure a completely flawless joint. “Sheffield Forgemasters’ skill, expertise and heritage is known the world over,” said Tom Mundy, NuScale’s managing director for the UK and Europe, speaking at a conference on the so-called “Northern Powerhouse” strategy. “Working together now is, I hope, the starting point of a lasting relationship that will ultimately see UK-manufactured SMRs generating clean reliable power for the UK grid by the 2020s.”

For Forgemasters, chief executive Graham Honeyman was keen to focus on the company’s expertise. “NuScale’s design is one of the most advanced in the world and this forging project will allow us to prove yet again that UK manufacturing is at the leading edge of global technological advancement,” he said. “The efficient factory manufacture of major components [for SMRs] will be crucial to seeing them deployed cost-effectively and Sheffield Forgemasters has an unparalleled track record in the production of civil nuclear forgings of this size.”

Swiss geoengineering start-up targets methane removal

Several rather dubious statistics in this report. IF methane had 120× the thermal effect of CO2 that would be TWO orders of magnitude. Two is not...