Using nanoparticles in a manufacturing environment is problematic. In their dry form, they have a low density, are electrostatic and can travel in the air. This makes them a potential environmental or health hazard and a challenge to handle.

Until recently, nanoparticles could only be used if they were in liquid solvent suspensions. However, in such a form, their applications are limited. Manufacturers would prefer them in a safe, dry form so that they could be used in conventional powder processing equipment to build ceramic or metal parts.

Now, a team from GEA Niro has developed a system that not only eliminates the health risks involved in handling the particles but also helps manufacturers to exploit the enhanced strength and fatigue characteristics of the materials.

Michael Wahlberg, head of GEA Niro’s Test and Development Centre in Denmark, said the rationale was to produce a nanostructured material that could be used in dry processes as easily as the powders being used today.

The company’s engineers built on years of experience of developing systems for drying liquid, particulate and solid materials, tailoring a more traditional system to control the production of nanostructured granules in a closed-loop environment.

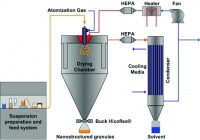

’In the new drying process, nanoparticles suspended in a solvent are pumped into the top of a spray dryer through one or more nozzles that atomise the suspension into fine droplets of around 20 and 50 microns in size,’ said Wahlberg. ’Heated air is simultaneously pumped into the chamber, where it is mixed with the atomised nanoparticle suspension.’

Inside the chamber, the hot air dries the atomised nanoparticle suspension, evaporating the liquid – a process that leaves the solid nanoparticles inside a number of nanostructured, micron-sized granules. Each granule can consist of up to a billion nanoparticles. The granules then fall to the bottom of the dryer where they can be collected.

According to Wahlberg, one of the keys to ensuring the effectiveness of the system was to optimise the mixing of the air and the particles.

To do this, the engineers utilised computational fluid dynamics to simulate the drying process until they found the optimal mixing conditions – ensuring that no wet particles deposited on the drying chamber walls, the integrated filter bags or the fluid bed at the bottom of the drying chamber.

The design of the new system also means that no particles can escape from the dryer until they have agglomerated with other particles The humid air from the dryer is then filtered to remove any particles left in the air stream. Next, it is fed into a condenser where the solvent vapour used to suspend the nanoparticles is collected. A fan then blows the dry air back through a heater before it re-enters the drying chamber.

According to Wahlberg, when the filler bag containing the granules is removed from the system, there is no risk of nanoparticles escaping, thanks to a Hycoflex valve that closes off any path into the dryer while the filler bag containing the nano-structured granules is replaced.

He added that the company has manufactured a laboratory-scale dryer capable of producing titanium dioxide and silicon dioxide nanostructured granules, for example, at a rate of 250g to 1,000g of granules per hour. Wahlberg believes the system could be scaled up to produce granules in production quantities at a rate of several tons of powder per hour.

With the laboratory-scale dryer complete, GEA Niro is actively soliciting interest from companies that are experimenting with the use of nanotechnology in their manufacturing processes.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...