Researchers in the pharmaceutical industry need to be able to test prospective drug compounds under conditions as close as possible to those inside living tissue before they begin to undertake clinical trials.

Chemical tests are among the oldest methods for determining the activity of compounds, but a test tube cannot replicate the complex environments in which biological activity takes place.

“The human body is largely made up of anisotropic [having different properties in different directions], hierarchical, and mostly three dimensional structures,” explained Prof Avfaro Mata, of the Queen Mary's School of engineering and materials science in London. “New ways to fabricate environments that can recreate physical and chemical features of such structures would have important implications in the way more efficient drugs are developed or more functional tissue and organ constructs can be engineered."

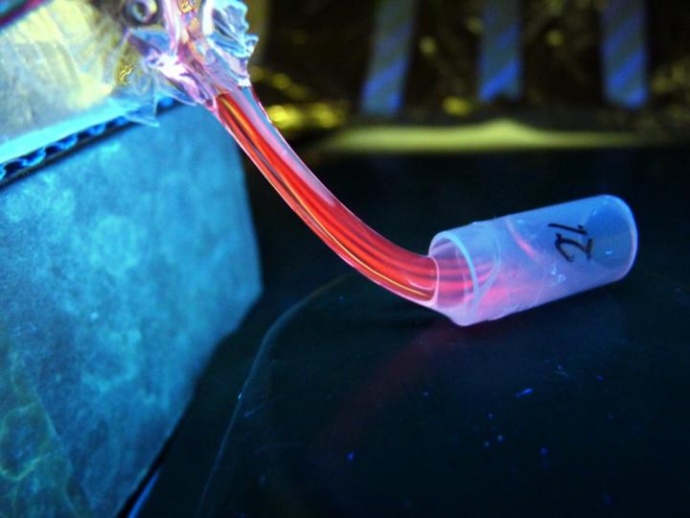

Mata and his colleagues have devised a method that uses an electrical field and porous mask to print patterns of molecules onto and into hydrogels. The printing method known as 3DEAL, is described in Advanced Functional Materials and can localise different types of molecules with microscale resolution to construct an environment such as might be found inside a living organ where drug compounds might encounter specifically shaped proteins.

Some of the patterns that can be printed include parallel and perpendicular columns, curved lines, gradients of molecular composition, and patterns of multiple proteins with sizes ranging from microns to tens of centimetres in size and depth. This, the researchers claim, could be used to design drug screening platforms or complex tissue-engineered structures.

"A major advantage of the technique is its robustness and cost-effectiveness,” said Gastón Primo, a co-author of the paper. “It is simple and can be used with different types of readily available hydrogels and be patterned with different types of molecules."

Nanogenerator consumes CO2 to generate electricity

Whoopee, they've solved how to keep a light on but not a lot else.