The use of graphene in batteries, composites, micro-sensors and ion-exchange membranes will all be investigated as part of a new collaborative research program.

The program, which will bring together researchers at Manchester University and the Masdar Institute of Science and Technology in Abu Dhabi, will focus on three projects covering the use of graphene and two dimensional materials in a range of applications.

Graphene is a single layer of carbon atoms, which is 10 times stronger than steel while 1000 times lighter than a sheet of paper per unit area.

In one of the projects, researchers from both organisations will develop low-cost ink-jet printing techniques for building micro-sensors designed to operate in the challenging environments found in high temperature energy and military applications.

Meanwhile, a separate team will investigate the benefits of using graphene-based ion exchange membranes in water desalination.

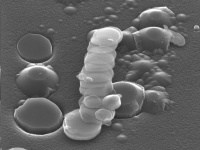

Finally, researchers will attempt to develop low-density graphene nanocomposite foams for use in batteries and supercapacitors, and to stiffen composite materials.

The advantage of using a 2D material like graphene in battery electrodes, for example, is that it has a very high surface area, and yet is only one atom thick, according to Prof Brian Derby at Manchester University, who is a member of the research team.

“But in order for the material to be useful, the atom-thick layers have to be packaged in a 3D object,” he said.

So the researchers are attempting to build foams out of graphene, he said. “We’re trying to develop ways of packaging these materials so that they assemble in space, but hold their surface area as much as possible.”

The team also hopes to develop composites in which very fine flakes of graphene are dispersed within a polymer matrix. This should allow for the efficient transfer of stress from the polymer to the graphene flakes, creating a stronger, but still workable composite, said Derby.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...