The leak was reported as being caused by a faulty seal in one of the ship’s propeller shafts, which was causing the ingress of 200 litres of sea water an hour.

HMS Queen Elizabeth is the first of two new UK aircraft carriers being built in the UK to enter service. These are the largest ever vessels to be built for the Royal Navy.

Much like any commissioning exercise, sea trials are carried out to ensure a vessel’s seaworthiness, prompting us to ask if it was fair or relevant for the national press to report the 'fault'.

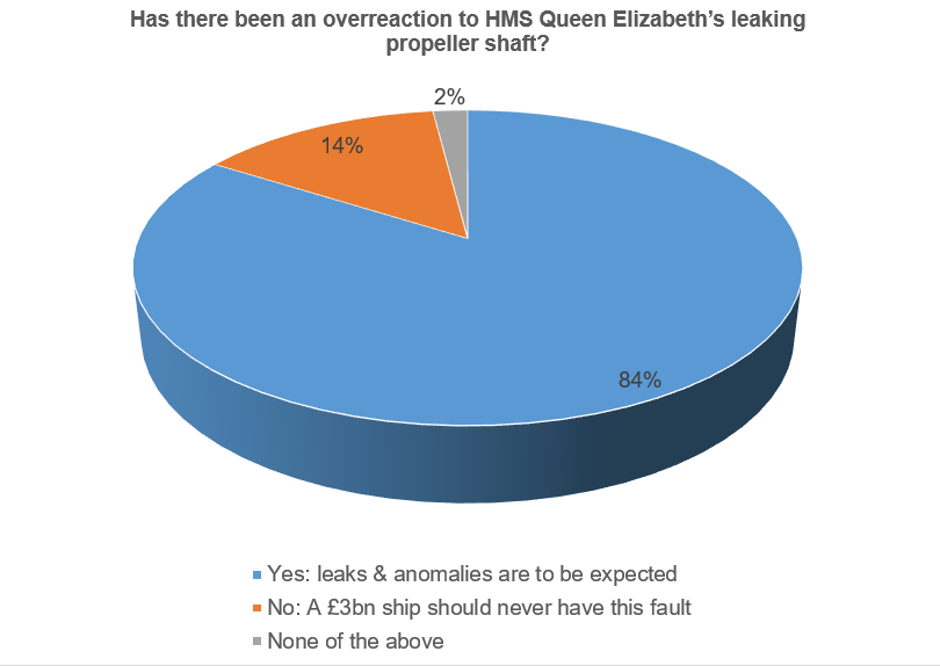

A total of 1,250 Engineer readers responded to the poll, with the vast majority (84 per cent) agreeing that there had been an overreaction and that such leaks and anomalies are to be expected.

Only 14 per cent agreed that — at a cost of £3bn — the carrier should not have such a fault. The remaining two per cent elected to choose the ‘none of the above option’.

To date, the poll has garnered 55 comments with many decrying national media outlets and others identifying what they see as the bigger issue, namely a lack of clarity about aircraft for the carriers.

Comments focused also on the technical elements arising from the story, including one from Tony Prince CEng who wrote: ‘As a marine engineer, I think this problem is not as trivial as it looks. Modern stern tubes are not old fashioned packed glands. They are oil filled with mechanical seals at either end. There is a header tank maintaining a positive pressure in the bearing. If there is a leaking outer seal, then oil will leak out. Sea water should never leak into the bearing, or the ship.’

Jonathan Douglas added: ‘Stern glands are always a source of issues for ships. This seems a rather serious fault, but the servicing of moving parts is what it is and can’t be ignored. I doubt many journalists have much idea what is actually involved.’

What do you think? Continue the debate using Comments below.

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...