Complex crystalline minerals known as perovskites have been a matter of interest in solar cell research for some years, as they have the potential to be far cheaper than cells made from pure silicon. However, although perovskites are efficient at freeing electrons when struck by photons, one barrier to their production has been the difficulty in extracting these freed electrons from the crystal structure so they can flow through a circuit.

Researchers at the University of Toronto (U of T) now claim to have developed a method for achieving this goal. Using chemical reactions to make an electron-selective layer (ESL) in direct contact with perovskite-containing layer, they claim that this method could allow perovskite solar cells to be fabricated by a cheap printing process.

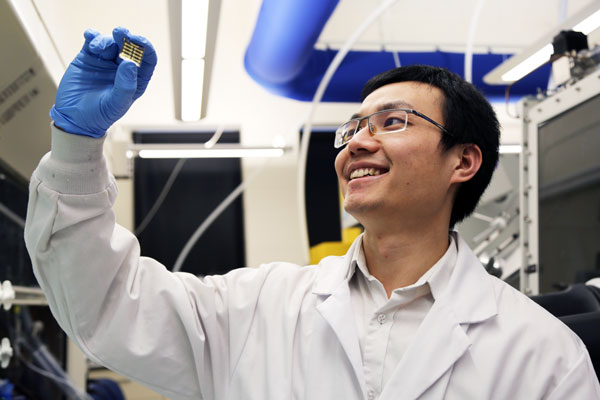

One of the advantages of perovskites is that micro-crystals of the substance can be mixed into an organic ink and printed directly onto glass, plastic or other materials using standard inkjet technology. But the ESL problem has meant that these printed films could not be used as functional cells. "The most effective materials for making ESLs start as a powder and have to be baked at high temperatures, about 500° C," explained Hairen Tan of the department of computing and electrical engineering at U of T, who led the research. "You can't put that on top of a sheet of flexible plastic or on a fully fabricated silicon cell – it will just melt."

Tan’s team has developed a method for making an ESL from nanoparticles of titanium dioxide in solution. These are coated with chlorine, which, they explain in a paper in Science, helps them to bind onto the perovskite layer, which can be fabricated by printing. Although some heat is required to activate the reaction that forms the film, the temperature never exceeds 150°C – low enough to be compatible with many plastics.

Tan claims that the solution-grown ESL produces a photovoltaic cell with the perovskite layer with an efficiency of 20.1 per cent. By comparison, perovskite cells made using a high temperature ESL have a highest-recorded efficiency of 22.1 per cent, and the best silicon solar cells are at 26.3 per cent. "This is the best ever reported for low-temperature processing techniques," he said. Moreover, the cells retained 90 per cent of their efficiency after 500 hours of use, in contrast to other perovskite cells which can suffer stability problems.

The research also open opens up the possibility of hybrid perovskite-silicon cells, Tan adds. "With our low-temperature process, we could coat our perovskite cells directly on top of silicon without damaging the underlying material," he said . "If a hybrid perovskite-silicon cell can push the efficiency up to 30 per cent or higher, it makes solar power a much better economic proposition."

Red Bull makes hydrogen fuel cell play with AVL

Formula 1 is an anachronistic anomaly where its only cutting edge is in engine development. The rules prohibit any real innovation and there would be...